Electromechanical relays rely on electromagnetic coils and mechanical moving parts to detect faults and trigger circuit interruptions, offering simplicity but slower response times. Digital protection relays use microprocessors to analyze electrical signals with high precision and customizable settings, enhancing accuracy and speed in fault detection and system control. The shift towards digital relays supports advanced diagnostics, remote monitoring, and integration with smart grid technologies.

Table of Comparison

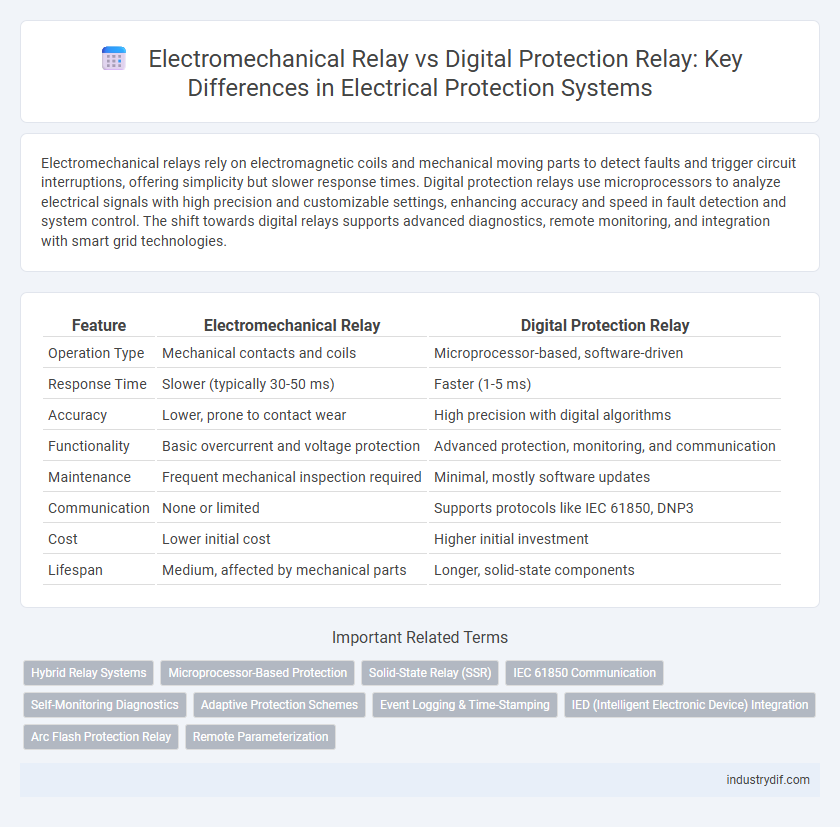

| Feature | Electromechanical Relay | Digital Protection Relay |

|---|---|---|

| Operation Type | Mechanical contacts and coils | Microprocessor-based, software-driven |

| Response Time | Slower (typically 30-50 ms) | Faster (1-5 ms) |

| Accuracy | Lower, prone to contact wear | High precision with digital algorithms |

| Functionality | Basic overcurrent and voltage protection | Advanced protection, monitoring, and communication |

| Maintenance | Frequent mechanical inspection required | Minimal, mostly software updates |

| Communication | None or limited | Supports protocols like IEC 61850, DNP3 |

| Cost | Lower initial cost | Higher initial investment |

| Lifespan | Medium, affected by mechanical parts | Longer, solid-state components |

Introduction to Electromechanical and Digital Protection Relays

Electromechanical relays operate using physical moving components and electromagnetic coils to detect faults and initiate circuit interruptions, providing reliable but slower response times in electrical protection systems. Digital protection relays utilize microprocessors and advanced algorithms for faster fault detection, precise monitoring, and enhanced communication capabilities within modern smart grid environments. The transition from electromechanical to digital protection relays improves accuracy, flexibility, and integration in power system protection and control.

Key Differences Between Electromechanical and Digital Relays

Electromechanical relays rely on mechanical moving parts and electromagnetic coils to detect faults, resulting in slower response times and higher maintenance requirements compared to digital relays. Digital protection relays use microprocessors to analyze electrical parameters with superior accuracy, configurable settings, and faster trip decisions, enhancing system reliability and protection coordination. Unlike electromechanical relays, digital relays offer advanced communication capabilities and self-diagnostic features, enabling integration with modern smart grid technologies.

Working Principle of Electromechanical Relays

Electromechanical relays operate by using an electromagnetic coil to physically move contacts that open or close electrical circuits, relying on mechanical movement triggered by current flow. When current passes through the coil, it creates a magnetic field that attracts an armature, causing a switch action that controls power to the load. This mechanical switching mechanism is slower and more prone to wear compared to the solid-state operation of digital protection relays.

Operation and Technology Behind Digital Protection Relays

Digital protection relays utilize microprocessors to monitor electrical parameters with high accuracy, enabling fast and precise fault detection and isolation compared to electromechanical relays. These relays employ algorithms and real-time data processing to analyze voltage, current, and frequency, ensuring adaptive and reliable protection for power systems. The underlying technology integrates communication protocols and programmable logic, facilitating remote configuration, diagnostics, and integration into smart grid infrastructures.

Advantages of Electromechanical Relays

Electromechanical relays offer robust physical isolation between control and load circuits, ensuring high dielectric strength and reliable operation in harsh industrial environments. They feature a simple construction that allows easy troubleshooting and maintenance, reducing downtime during faults. Their inherent ability to handle high surge currents makes them ideal for protecting electrical equipment against transient overcurrents.

Benefits of Digital Protection Relays

Digital protection relays offer enhanced precision and faster response times compared to electromechanical relays, enabling more reliable fault detection and system protection. They provide advanced features such as real-time monitoring, fault recording, and remote communication capabilities, which improve overall power system management. Their programmability and adaptability allow for easier integration into modern smart grids and automation systems, increasing operational efficiency and reducing maintenance costs.

Common Applications for Each Relay Type

Electromechanical relays are commonly used in industrial machinery control, motor protection, and simple overload protection due to their robust physical design and reliability in harsh environments. Digital protection relays are prevalent in modern power systems, including transmission and distribution networks, offering advanced features like real-time monitoring, fault analysis, and remote communication capabilities. Both relay types serve critical roles in electrical protection, with electromechanical relays favored for straightforward, cost-effective applications and digital relays preferred for complex, programmable protection schemes.

Reliability and Maintenance Considerations

Electromechanical relays offer high reliability due to their simple mechanical design but require frequent maintenance to prevent contact wear and failure. Digital protection relays provide enhanced reliability with self-diagnostic features, minimal mechanical parts, and easier firmware updates, reducing maintenance efforts significantly. Maintenance of digital relays primarily involves software management and periodic testing, improving operational efficiency compared to electromechanical counterparts.

Comparative Cost Analysis and Lifecycle

Electromechanical relays typically incur higher maintenance costs due to mechanical wear and shorter lifespans averaging 10 to 15 years, whereas digital protection relays offer lower operational expenses and longer lifecycles exceeding 20 years with software updates improving functionality. Initial capital expenditure for electromechanical relays is generally lower, but total cost of ownership often becomes higher over time because of frequent testing and calibration requirements. Digital protection relays provide improved reliability and adaptability, reducing unplanned outages and extending asset life, which translates into cost savings throughout their extended service duration.

Future Trends in Relay Protection Technology

Electromechanical relays are rapidly being outpaced by digital protection relays due to advancements in microprocessor technology, offering enhanced accuracy, faster response times, and extensive diagnostic features. Future trends in relay protection technology emphasize smart grid integration, IoT connectivity, and machine learning algorithms to enable predictive maintenance and real-time system optimization. These innovations will drive increased grid reliability, reduced downtime, and more efficient fault detection and isolation.

Related Important Terms

Hybrid Relay Systems

Hybrid relay systems combine the reliability of electromechanical relays with the precision of digital protection relays, enhancing fault detection and system stability in electrical networks. These systems leverage the mechanical robustness and straightforward operation of electromechanical relays alongside the advanced data processing, communication capabilities, and configurability of digital relays to optimize protective relaying performance.

Microprocessor-Based Protection

Microprocessor-based digital protection relays offer advanced functionality, precise fault detection, and real-time data analysis compared to traditional electromechanical relays, enhancing power system reliability. Their programmable nature enables adaptive protection schemes, communication capabilities, and integration with smart grid technologies for efficient system monitoring and control.

Solid-State Relay (SSR)

Solid-State Relays (SSRs) offer faster switching times and higher reliability compared to traditional electromechanical relays, utilizing semiconductor components to eliminate moving parts and reduce wear. SSRs in digital protection systems enhance signal processing accuracy and longevity, making them ideal for automated, high-speed electrical protection applications.

IEC 61850 Communication

Electromechanical relays rely on mechanical components for operation and lack advanced communication capabilities, whereas digital protection relays utilize microprocessors and support IEC 61850 communication protocols, enabling real-time data exchange and interoperability in smart grid systems. IEC 61850 facilitates standardized, high-speed communication between digital relays and substation automation equipment, enhancing protection, control, and monitoring efficiency compared to traditional electromechanical relays.

Self-Monitoring Diagnostics

Electromechanical relays lack advanced self-monitoring diagnostics, making fault detection and maintenance less efficient compared to digital protection relays, which continuously perform internal health checks and provide real-time status reports to enhance system reliability. Digital protection relays integrate self-diagnostic algorithms and communication interfaces, enabling proactive fault identification and minimizing downtime in electrical systems.

Adaptive Protection Schemes

Electromechanical relays, relying on mechanical components and fixed settings, lack the flexibility required for adaptive protection schemes that dynamically respond to system conditions. Digital protection relays utilize microprocessor-based technology, enabling real-time data analysis and adaptive algorithms to optimize fault detection and system stability under varying network scenarios.

Event Logging & Time-Stamping

Electromechanical relays provide basic event logging with limited accuracy and no precise time-stamping, relying mainly on manual inspection and external recorders. Digital protection relays feature advanced event logging capabilities with high-resolution time-stamping using synchronized clocks like GPS, enabling detailed fault analysis and improved system diagnostics.

IED (Intelligent Electronic Device) Integration

Electromechanical relays operate through mechanical components and are limited in their ability to interface with modern Intelligent Electronic Devices (IEDs), whereas digital protection relays use microprocessor technology for seamless IED integration, enabling real-time data communication, enhanced diagnostics, and remote monitoring. Digital protection relays support advanced protocols like IEC 61850, facilitating efficient automation and interoperability within smart grid systems.

Arc Flash Protection Relay

Electromechanical relays rely on physical moving parts and mechanical contacts, which often result in slower response times and increased wear, limiting their effectiveness in arc flash protection. Digital protection relays use microprocessors to quickly detect arc flash conditions and isolate faults with high precision, enhancing safety and minimizing damage in electrical systems.

Remote Parameterization

Electromechanical relays require manual adjustments and on-site configuration for parameter changes, limiting remote control capabilities. Digital protection relays enable efficient remote parameterization through communication protocols like IEC 61850, facilitating real-time monitoring and faster system adaptability.

Electromechanical Relay vs Digital Protection Relay Infographic

industrydif.com

industrydif.com