Traditional substations rely heavily on analog equipment and manual controls, which can limit efficiency and increase maintenance costs. Digital substations utilize advanced communication protocols and intelligent electronic devices (IEDs) to enable real-time monitoring, automation, and improved fault detection. This integration of digital technology enhances grid reliability, reduces operational expenses, and supports the modernization of power systems.

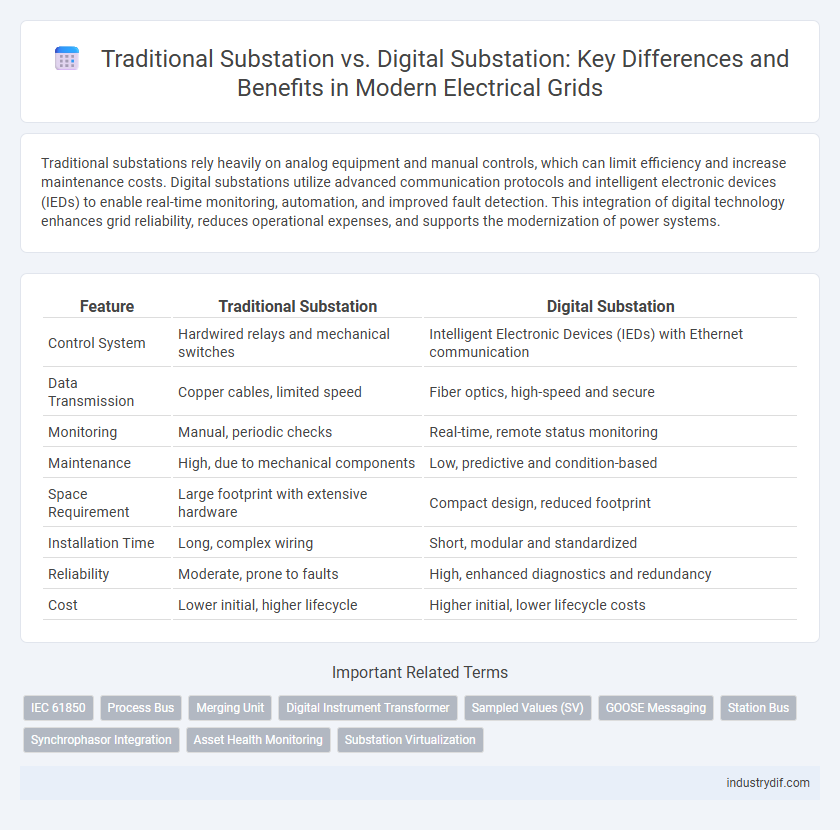

Table of Comparison

| Feature | Traditional Substation | Digital Substation |

|---|---|---|

| Control System | Hardwired relays and mechanical switches | Intelligent Electronic Devices (IEDs) with Ethernet communication |

| Data Transmission | Copper cables, limited speed | Fiber optics, high-speed and secure |

| Monitoring | Manual, periodic checks | Real-time, remote status monitoring |

| Maintenance | High, due to mechanical components | Low, predictive and condition-based |

| Space Requirement | Large footprint with extensive hardware | Compact design, reduced footprint |

| Installation Time | Long, complex wiring | Short, modular and standardized |

| Reliability | Moderate, prone to faults | High, enhanced diagnostics and redundancy |

| Cost | Lower initial, higher lifecycle | Higher initial, lower lifecycle costs |

Overview of Traditional and Digital Substations

Traditional substations rely on analog equipment and manual control systems for power distribution and monitoring, often resulting in slower response times and limited real-time data access. Digital substations integrate intelligent electronic devices (IEDs), digital communication protocols like IEC 61850, and advanced automation to enhance efficiency, reliability, and remote operation capabilities. The shift to digital substations enables improved fault detection, predictive maintenance, and streamlined grid management compared to conventional setups.

Key Components in Traditional Substations

Traditional substations rely on mechanical circuit breakers, electromechanical relays, and analog metering instruments as key components for power switching, protection, and monitoring. Control panels typically include physical wiring and manual switches, while communication relies on hardwired connections such as copper cables. These substations use conventional busbars and transformers for voltage regulation and distribution, lacking the integration and real-time data processing found in digital substations.

Evolution to Digital Substation Technology

Traditional substations rely heavily on analog equipment and manual operations, leading to limited real-time monitoring and slower fault detection. Digital substations integrate intelligent electronic devices (IEDs) with advanced communication protocols like IEC 61850, enabling enhanced automation, precise control, and remote operation. This evolution to digital technology improves grid reliability, efficiency, and facilitates seamless integration of renewable energy sources.

Core Features of Digital Substations

Digital substations integrate advanced communication protocols like IEC 61850 for real-time data exchange, enhancing operational efficiency and fault detection. They utilize intelligent electronic devices (IEDs) and digital relays, enabling precise monitoring and control with minimal physical wiring. Core features include improved automation, remote accessibility, and enhanced cybersecurity measures compared to traditional substations.

Communication Protocols: Analog vs Digital

Traditional substations rely on analog communication protocols such as 4-20mA signals and hardwired connections, which limit data transmission speed and flexibility. Digital substations utilize standardized digital communication protocols like IEC 61850, enabling real-time data exchange, enhanced interoperability, and improved monitoring and control capabilities. The shift from analog to digital communication significantly boosts operational efficiency, fault detection, and system integration in modern electrical grids.

System Reliability and Performance Comparison

Traditional substations rely on analog equipment and manual controls, leading to slower fault detection and longer downtime, which can reduce overall system reliability. Digital substations use advanced sensors, real-time data analytics, and automated controls to enhance fault diagnosis speed and accuracy, significantly improving performance and minimizing outage durations. The integration of intelligent electronic devices (IEDs) in digital substations enables predictive maintenance and remote monitoring, thereby maximizing operational efficiency and system reliability.

Cybersecurity in Substations: Old vs New

Traditional substations rely on isolated, analog systems with limited cybersecurity measures, making them vulnerable to physical and cyber intrusions. Digital substations utilize advanced IP-based communication networks and encryption protocols, enhancing real-time monitoring and resilience against cyber threats. Implementing robust firewalls, intrusion detection systems, and secure remote access in digital substations significantly mitigates risks compared to legacy infrastructure.

Cost Implications: Installation and Maintenance

Traditional substations involve higher installation costs due to extensive physical infrastructure, wiring, and manual equipment, while digital substations reduce these expenses by utilizing advanced automation and compact, integrated systems. Maintenance costs for traditional substations are elevated because of frequent manual inspections and hardware replacements, in contrast to digital substations that enable remote monitoring, predictive maintenance, and faster fault detection, significantly lowering operational expenses. Investment in digital substations offers long-term cost savings through enhanced efficiency and reduced downtime, despite higher initial technology procurement costs.

Integration with Smart Grids and IoT

Traditional substations rely on analog equipment and limited communication capabilities, which restrict their integration with smart grids and IoT devices. Digital substations utilize advanced sensors, real-time data exchange, and standardized protocols like IEC 61850, enabling seamless connectivity and enhanced automation within smart grid architectures. This digital transformation facilitates remote monitoring, predictive maintenance, and optimized energy management, significantly improving grid reliability and efficiency.

Future Trends in Substation Modernization

Digital substations leverage advanced communication protocols like IEC 61850 to enable real-time data exchange and enhanced automation, significantly improving grid reliability and operational efficiency. Future trends emphasize integrating Internet of Things (IoT) sensors and artificial intelligence for predictive maintenance and adaptive fault detection in both traditional and digital substations. Enhanced cybersecurity measures are becoming critical as digital substations expand their connectivity to protect against evolving cyber threats in modern power systems.

Related Important Terms

IEC 61850

IEC 61850 enables digital substations to offer enhanced interoperability, real-time communication, and advanced automation compared to traditional substations reliant on hardwired connections and proprietary protocols. This international standard facilitates seamless integration of intelligent electronic devices (IEDs), improving system reliability, scalability, and efficient data exchange in modern power grid infrastructure.

Process Bus

Traditional substations rely on copper wiring for analog signal transmission, causing latency and vulnerability to electromagnetic interference, while digital substations utilize process bus technology with fiber-optic communication, enabling real-time data exchange and enhanced accuracy. Process bus integration in digital substations facilitates centralized control and monitoring, reduces installation complexity, and improves system scalability and cybersecurity.

Merging Unit

Merging units in digital substations replace traditional circuit breaker panels by converting analog signals into digital data streams for precise and real-time monitoring. Unlike traditional substations, this integration of merging units enhances data accuracy, enables faster fault detection, and supports advanced automation and remote control capabilities.

Digital Instrument Transformer

Digital instrument transformers in digital substations provide enhanced accuracy, real-time data transmission, and improved safety compared to traditional electromagnetic instrument transformers. They support advanced monitoring and control functions, enabling smarter grid management and reducing maintenance costs.

Sampled Values (SV)

Sampled Values (SV) in digital substations enable real-time transmission of precise, high-resolution current and voltage measurements over Ethernet, vastly improving accuracy and interoperability compared to traditional substations relying on analog signals and hardwired connections. This transition enhances protection, control, and monitoring capabilities, reduces wiring complexity, and supports advanced analytics in modern electrical grids.

GOOSE Messaging

GOOSE messaging in digital substations enables real-time, high-speed communication between Intelligent Electronic Devices (IEDs), significantly enhancing fault detection and system automation compared to traditional substations that rely on slower, hardwired signaling methods. This protocol uses Ethernet-based multicast communication to reduce wiring complexity and improve interoperability, increasing operational efficiency and reliability in modern power grid management.

Station Bus

Traditional substations utilize copper-based station bus systems that often suffer from signal degradation and require extensive wiring, whereas digital substations employ fiber-optic station buses enabling high-speed data transmission, enhanced reliability, and streamlined communication between Intelligent Electronic Devices (IEDs). The adoption of digital station buses significantly reduces electromagnetic interference, simplifies maintenance, and supports real-time monitoring and control, driving efficiency in modern electrical grid operations.

Synchrophasor Integration

Traditional substations rely on analog devices and limited data accuracy, hindering real-time monitoring and control, whereas digital substations integrate synchrophasor technology for high-resolution, time-synchronized measurements that enhance grid visibility and fault detection. Synchrophasor integration enables advanced situational awareness and precise dynamic system analysis, significantly improving operational efficiency and reliability in digital substations.

Asset Health Monitoring

Digital substations utilize advanced sensors and IoT technology to provide real-time asset health monitoring, enabling predictive maintenance and reducing downtime compared to traditional substations reliant on periodic manual inspections. Enhanced data analytics and remote diagnostics in digital substations improve operational efficiency and extend the lifespan of critical electrical infrastructure.

Substation Virtualization

Substation virtualization transforms traditional substations by replacing physical equipment with software-based systems, enhancing real-time monitoring, control, and automation capabilities. This shift reduces operational costs, improves grid reliability, and enables seamless integration with smart grid technologies through digital communication protocols and centralized management platforms.

Traditional Substation vs Digital Substation Infographic

industrydif.com

industrydif.com