Assaying provides precise chemical analysis of mineral samples through laboratory techniques, ensuring accurate detection of valuable elements. Real-time geochemical sensing offers continuous, on-site measurements, enabling faster decision-making and immediate adjustments during mining operations. Integrating both methods enhances resource estimation accuracy and optimizes extraction efficiency.

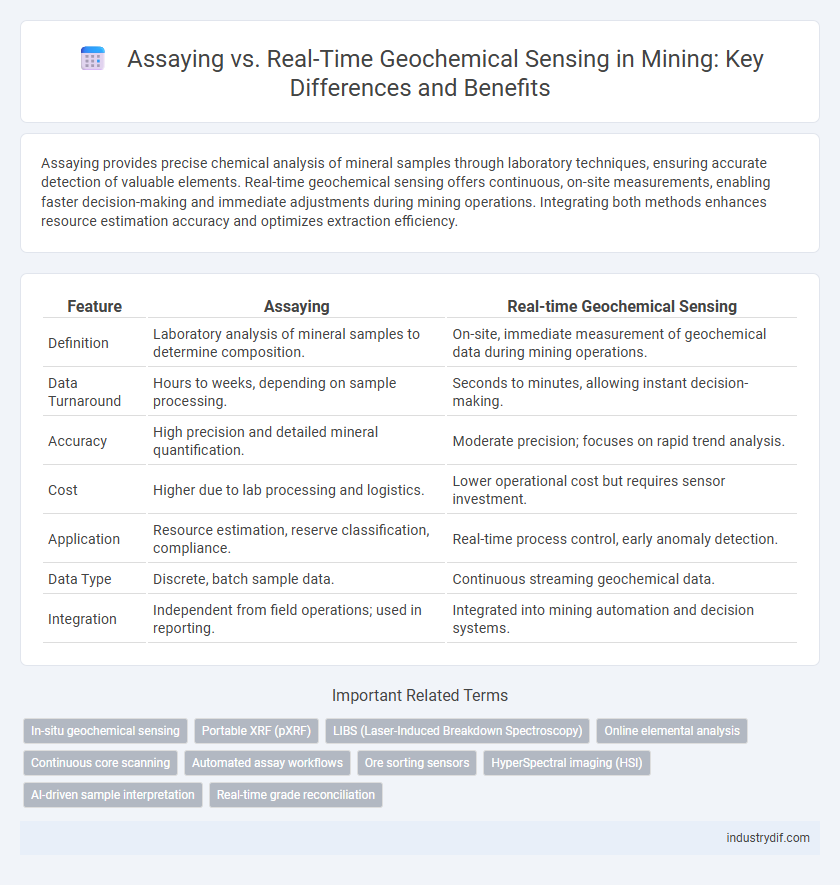

Table of Comparison

| Feature | Assaying | Real-time Geochemical Sensing |

|---|---|---|

| Definition | Laboratory analysis of mineral samples to determine composition. | On-site, immediate measurement of geochemical data during mining operations. |

| Data Turnaround | Hours to weeks, depending on sample processing. | Seconds to minutes, allowing instant decision-making. |

| Accuracy | High precision and detailed mineral quantification. | Moderate precision; focuses on rapid trend analysis. |

| Cost | Higher due to lab processing and logistics. | Lower operational cost but requires sensor investment. |

| Application | Resource estimation, reserve classification, compliance. | Real-time process control, early anomaly detection. |

| Data Type | Discrete, batch sample data. | Continuous streaming geochemical data. |

| Integration | Independent from field operations; used in reporting. | Integrated into mining automation and decision systems. |

Introduction to Assaying and Real-time Geochemical Sensing

Assaying involves laboratory-based analysis of mineral samples to determine their precise chemical composition and grade, providing accurate and reliable data essential for resource evaluation. Real-time geochemical sensing employs in-field, on-site technologies such as portable XRF and LIBS to rapidly detect and quantify elemental concentrations during exploration or mining, enabling immediate decision-making. Combining assaying with real-time geochemical sensing enhances efficiency, reduces turnaround times, and improves the accuracy of mineral characterization throughout the mining process.

Historical Overview: Traditional Assaying Methods

Traditional assaying methods in mining have relied on laboratory-based techniques such as fire assay, atomic absorption spectroscopy (AAS), and inductively coupled plasma mass spectrometry (ICP-MS) to determine ore composition and metal content. These approaches provide high accuracy and reliable quantitative data but involve lengthy turnaround times due to sample preparation, transportation, and batch processing. The historical dependence on these conventional assays has shaped the industry's baseline for mineral evaluation before the advent of real-time geochemical sensing technologies.

Principles and Technologies Behind Real-time Geochemical Sensing

Real-time geochemical sensing in mining leverages advanced sensor technologies such as X-ray fluorescence (XRF), laser-induced breakdown spectroscopy (LIBS), and electrochemical sensors to instantly analyze mineral compositions directly in the field. These methods rely on principles of atomic emission, absorption, and fluorescence to detect elements with high precision, enabling rapid decision-making without the delays associated with traditional assaying. Benefits include continuous data acquisition, reduced sample preparation, and enhanced spatial resolution, which significantly improve exploration accuracy and operational efficiency compared to conventional laboratory-based assays.

Accuracy and Reliability: Comparing Analytical Results

Assaying delivers highly accurate and reliable analytical results through controlled laboratory conditions and standardized protocols, ensuring precise quantification of ore grade and composition. Real-time geochemical sensing provides rapid on-site measurements with moderate accuracy but can be influenced by environmental variables and sensor calibration, potentially affecting reliability. Combining both methods enhances overall data confidence by balancing the precision of assay results with the operational efficiency of real-time sensing.

Speed and Efficiency: Lab vs. Field-based Techniques

Assaying provides highly accurate laboratory results but often involves significant delays due to sample transport and processing times. Real-time geochemical sensing offers immediate, on-site analysis, dramatically increasing efficiency by enabling faster decision-making during exploration and mining operations. Field-based techniques reduce the turnaround time from days or weeks to minutes, optimizing resource allocation and minimizing operational downtime.

Impact on Exploration and Orebody Modelling

Assaying provides precise laboratory analysis of mineral content, crucial for accurate resource estimation and detailed orebody modelling. Real-time geochemical sensing enables immediate data acquisition in the field, accelerating decision-making and refining exploration targeting by identifying geochemical anomalies promptly. Integrating both methods enhances exploration efficiency and improves orebody models through continuous validation and dynamic updating of mineralization data.

Cost Implications and Resource Allocation

Assaying in mining involves laboratory analysis of rock or soil samples, incurring higher costs due to sample collection, preparation, and processing. Real-time geochemical sensing employs in-situ technologies, significantly reducing operational expenses by enabling immediate data acquisition and minimizing sample transport and lab work. Resource allocation shifts towards investing in advanced sensor technologies and data management systems rather than extensive laboratory infrastructure, optimizing cost-efficiency in exploration programs.

Technological Advancements in Sensing and Assaying

Technological advancements in mining have significantly enhanced assaying and real-time geochemical sensing by integrating high-precision instruments such as X-ray fluorescence (XRF) analyzers and laser-induced breakdown spectroscopy (LIBS). Real-time sensing enables immediate geochemical data acquisition on-site, drastically reducing turnaround times compared to traditional laboratory assaying methods that require sample preparation and transport. These innovations improve resource estimation accuracy and optimize decision-making during exploration and extraction processes.

Future Trends: Integration and Automation in Mining

Assaying remains the traditional benchmark for precise mineral composition analysis, while real-time geochemical sensing offers immediate data for dynamic decision-making in mining operations. Future trends emphasize integration of real-time sensors with automated drilling and processing systems to enhance efficiency and reduce human error. Advanced machine learning algorithms are increasingly applied to fuse assay results and live sensor data, driving predictive models for optimized resource extraction and environmental management.

Choosing the Right Approach: Factors for Decision-making

Choosing between assaying and real-time geochemical sensing in mining hinges on factors like accuracy requirements, project timeline, and budget constraints. Assaying provides high-precision elemental analysis but involves longer turnaround times and higher costs, making it suitable for detailed resource estimation. Real-time geochemical sensing offers rapid, on-site data collection enabling immediate decision-making, ideal for exploration phases and operational adjustments where timely information outweighs absolute precision.

Related Important Terms

In-situ geochemical sensing

In-situ geochemical sensing provides real-time, on-site analysis of mineral compositions, enhancing decision-making speed compared to traditional assaying methods that require sample extraction and laboratory processing. This advanced technology improves exploration efficiency by delivering immediate geochemical data, reducing operational downtime, and enabling continuous monitoring of mineralization trends in mining environments.

Portable XRF (pXRF)

Portable XRF (pXRF) technology offers rapid, on-site elemental analysis, enabling real-time geochemical sensing that enhances decision-making during exploration and mining operations. Compared to traditional assaying methods, pXRF provides immediate, non-destructive results with lower operational costs, although it may have limitations in detecting trace elements and requires calibration against laboratory assays for accuracy.

LIBS (Laser-Induced Breakdown Spectroscopy)

Laser-Induced Breakdown Spectroscopy (LIBS) offers real-time geochemical sensing by rapidly analyzing elemental composition on-site, enhancing decision-making efficiency compared to traditional laboratory assaying methods that require longer sample preparation and turnaround times. LIBS technology enables high-resolution, in-situ detection of trace metals and minerals, significantly improving the speed and accuracy of mineral exploration and resource estimation in mining operations.

Online elemental analysis

Online elemental analysis through real-time geochemical sensing offers continuous, in-situ monitoring of mineral compositions, enabling immediate decision-making during mining operations. This contrasts with traditional assaying, which provides delayed laboratory results and may limit the speed and accuracy of resource evaluation.

Continuous core scanning

Continuous core scanning revolutionizes mineral exploration by providing rapid, non-destructive, and high-resolution geochemical data directly from drill cores, enabling better decision-making compared to traditional assaying methods that require lab-based sample processing and longer turnaround times. This real-time geochemical sensing enhances data accuracy and spatial resolution, optimizing resource estimation and reducing exploration costs in mining projects.

Automated assay workflows

Automated assay workflows enhance mining efficiency by integrating precise sample preparation, analysis, and data processing, reducing human error compared to traditional assaying methods. Real-time geochemical sensing complements these workflows by providing continuous, in-situ elemental composition data, enabling faster decision-making and resource optimization.

Ore sorting sensors

Ore sorting sensors enhance the accuracy of real-time geochemical sensing by providing rapid, non-destructive analysis of mineral content, improving the efficiency of ore grade assessment and waste rejection. While traditional assaying offers precise laboratory-based chemical analysis, ore sorting technology enables on-site, high-throughput detection that optimizes resource utilization and reduces processing costs in mining operations.

HyperSpectral imaging (HSI)

HyperSpectral Imaging (HSI) offers real-time geochemical sensing capabilities by capturing detailed spectral information across numerous bands, enabling rapid mineral identification and mapping with high spatial resolution. This contrasts with traditional assaying methods, which require physical sample collection and laboratory analysis, resulting in longer turnaround times and limited spatial coverage.

AI-driven sample interpretation

Assaying provides precise laboratory analysis of mineral samples, while real-time geochemical sensing leverages AI-driven algorithms to interpret complex geochemical data instantly at the drill site, enhancing decision-making speed and accuracy. AI integration in geochemical sensing improves the identification of ore zones by analyzing multi-element data patterns, reducing the reliance on time-consuming assay turnaround times.

Real-time grade reconciliation

Real-time grade reconciliation leverages continuous geochemical sensing to provide instant feedback on ore quality, enhancing decision-making accuracy compared to traditional periodic assaying. This approach reduces sampling errors and operational lag, optimizing mineral recovery and improving overall mine efficiency.

Assaying vs Real-time geochemical sensing Infographic

industrydif.com

industrydif.com