Conventional mining primarily involves extracting minerals from terrestrial environments, utilizing established methods such as open-pit and underground mining, which have well-known environmental impacts like habitat destruction and soil erosion. Deep-sea mining targets mineral-rich deposits on the ocean floor, offering access to valuable resources like polymetallic nodules, but it poses significant risks to fragile marine ecosystems that are not yet fully understood. Advances in technology and regulatory frameworks are essential to balance resource extraction with environmental sustainability in both mining approaches.

Table of Comparison

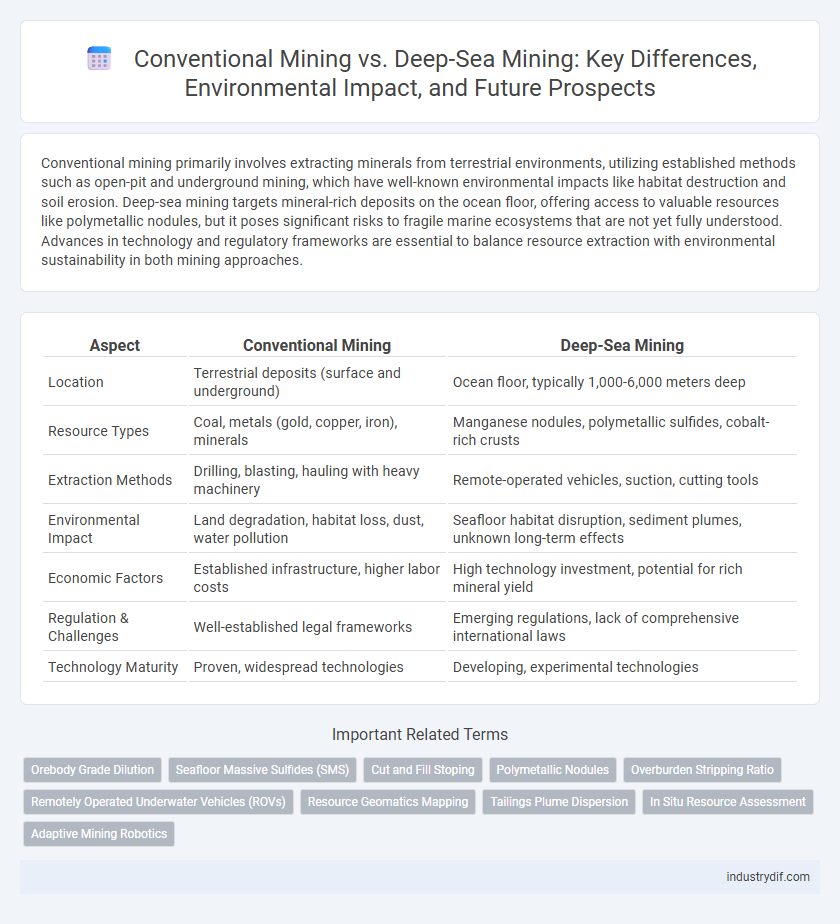

| Aspect | Conventional Mining | Deep-Sea Mining |

|---|---|---|

| Location | Terrestrial deposits (surface and underground) | Ocean floor, typically 1,000-6,000 meters deep |

| Resource Types | Coal, metals (gold, copper, iron), minerals | Manganese nodules, polymetallic sulfides, cobalt-rich crusts |

| Extraction Methods | Drilling, blasting, hauling with heavy machinery | Remote-operated vehicles, suction, cutting tools |

| Environmental Impact | Land degradation, habitat loss, dust, water pollution | Seafloor habitat disruption, sediment plumes, unknown long-term effects |

| Economic Factors | Established infrastructure, higher labor costs | High technology investment, potential for rich mineral yield |

| Regulation & Challenges | Well-established legal frameworks | Emerging regulations, lack of comprehensive international laws |

| Technology Maturity | Proven, widespread technologies | Developing, experimental technologies |

Overview of Conventional and Deep-Sea Mining

Conventional mining involves extracting minerals from terrestrial deposits through surface or underground methods, targeting resources such as coal, gold, and copper. Deep-sea mining focuses on harvesting polymetallic nodules, sulfides, and manganese crusts from the ocean floor, typically at depths of 1,000 to 6,000 meters. Both techniques address critical resource demands but differ significantly in environmental impact, technological requirements, and exploration challenges.

Key Processes in Conventional Mining

Conventional mining primarily involves extraction techniques such as open-pit mining, underground mining, and placer mining, where minerals are accessed through surface and subsurface operations. Key processes include drilling, blasting, ore hauling, and material processing, facilitating the recovery of metals like gold, copper, and coal from terrestrial deposits. These established methods rely on heavy machinery and extensive infrastructure to efficiently separate valuable minerals from ore.

Technological Innovations in Deep-Sea Mining

Deep-sea mining employs advanced remotely operated vehicles (ROVs) and autonomous underwater vehicles (AUVs) equipped with high-resolution sonar and robotic arms for precise extraction of polymetallic nodules, contrasting with conventional mining's reliance on surface-level machinery. Innovations such as real-time environmental monitoring systems and machine learning algorithms optimize resource identification and minimize ecological impact in deep-sea operations. These technological advancements enable access to previously untapped mineral deposits like cobalt, nickel, and rare earth elements critical for modern electronics.

Resource Types and Extraction Methods

Conventional mining primarily targets terrestrial mineral deposits such as coal, gold, and iron through surface or underground excavation techniques involving drilling, blasting, and hauling. Deep-sea mining focuses on extracting polymetallic nodules, cobalt-rich crusts, and hydrothermal vent sulfides located on the ocean floor using remotely operated vehicles and specialized suction or hydraulic systems. These distinct resource types and extraction methods reflect differing environmental challenges and technological requirements inherent in terrestrial versus marine mineral exploitation.

Environmental Impacts: Land vs. Ocean

Conventional mining causes deforestation, soil erosion, and contamination of freshwater systems through chemical runoff, leading to habitat loss and biodiversity decline on land. Deep-sea mining disrupts fragile ocean ecosystems, disturbing benthic habitats and releasing sediment plumes that can smother marine life and affect filter-feeding species. Both methods pose significant environmental threats, but deep-sea mining impacts underwater biodiversity in largely unexplored areas, complicating the assessment of long-term ecological consequences.

Economic Viability and Cost Analysis

Conventional mining benefits from established infrastructure and predictable costs, typically ranging from $40 to $150 per metric ton depending on mineral type and location, whereas deep-sea mining incurs higher initial capital expenditures due to advanced robotic technology and deep-water equipment, with projected costs between $200 to $400 per metric ton. Economic viability of deep-sea mining remains uncertain due to fluctuating commodity prices and regulatory challenges, while conventional mining maintains stable returns through proven extraction techniques. Cost analysis must factor in environmental mitigation, potential recovery rates, and market demand, making conventional mining currently more economically favorable, though deep-sea mining offers long-term resource potential.

Regulatory Frameworks and Compliance

Conventional mining operates under well-established regulatory frameworks encompassing environmental impact assessments, land use permits, and worker safety standards, regulated by national and international laws. Deep-sea mining faces emerging regulatory challenges with the International Seabed Authority (ISA) developing a comprehensive legal framework to balance mineral extraction with marine biodiversity protection in international waters. Compliance in deep-sea mining requires adherence to evolving environmental guidelines, monitoring protocols, and contract obligations to minimize ecological disruption while enabling sustainable resource exploitation.

Workforce Requirements and Safety Standards

Conventional mining demands a large workforce trained in surface and underground operations with established safety protocols to mitigate risks like cave-ins and exposure to hazardous materials. Deep-sea mining requires a specialized, smaller team skilled in remotely operated vehicle (ROV) technologies and underwater robotics, with stringent safety measures addressing high-pressure, low-visibility environments and potential ecological impacts. Both methods prioritize worker safety, but deep-sea mining introduces advanced technical challenges necessitating rigorous training and real-time monitoring systems.

Market Demand and Resource Availability

Conventional mining relies on terrestrial mineral deposits, which are becoming increasingly scarce and difficult to access, driving up production costs and limiting supply. Deep-sea mining offers access to vast, untapped polymetallic nodules and sulfide deposits containing critical metals like cobalt, nickel, and rare earth elements, potentially meeting rising market demand for batteries and electronics. Growing demand for sustainable and high-tech applications underscores the urgent need to develop deep-sea mining technologies as a complementary resource solution.

Future Prospects and Industry Trends

Conventional mining continues to evolve with advancements in automation and environmental management, maintaining a steady pace due to proven infrastructure and regulatory frameworks. Deep-sea mining offers promising access to abundant polymetallic nodules and rare earth elements crucial for renewable energy technologies, driving significant investment and exploration efforts despite regulatory uncertainties. Industry trends indicate a shift towards sustainable practices and incorporation of digital technologies, with growing emphasis on balancing economic benefits with ecological impact in both mining sectors.

Related Important Terms

Orebody Grade Dilution

Conventional mining typically experiences higher orebody grade dilution due to factors such as blasting fragmentation and manual extraction methods, which can mix high-grade ore with waste rock. Deep-sea mining, on the other hand, potentially offers lower dilution rates through targeted extraction techniques using remotely operated vehicles, although challenges in precise orebody delineation and seabed disturbance still impact overall grade control.

Seafloor Massive Sulfides (SMS)

Seafloor Massive Sulfides (SMS) deposits, rich in copper, zinc, gold, and silver, are typically targeted in deep-sea mining, contrasting with conventional mining that exploits terrestrial sulfide deposits. Deep-sea mining offers access to unique hydrothermal vent ecosystems and higher-grade SMS ore bodies, though it presents significant environmental and technical challenges compared to established land-based extraction methods.

Cut and Fill Stoping

Cut and fill stoping in conventional mining involves excavating ore in horizontal slices, backfilling mined-out areas with waste material to maintain stability, and is commonly used in underground mines with irregular ore bodies. Deep-sea mining, by contrast, targets polymetallic nodules or sulfide deposits on the ocean floor but lacks established cut and fill techniques, relying instead on remotely operated vehicles and sediment extraction methods adapted for high-pressure underwater environments.

Polymetallic Nodules

Conventional mining targets mineral deposits on land, extracting ores such as copper, nickel, and gold, whereas deep-sea mining focuses on polymetallic nodules found on the ocean floor, rich in manganese, cobalt, and rare earth elements essential for modern technologies. Polymetallic nodules, composed mainly of manganese, iron, nickel, copper, and cobalt, represent a promising resource for sustainable metal extraction with reduced terrestrial environmental impact compared to traditional mining operations.

Overburden Stripping Ratio

Conventional mining typically exhibits a lower overburden stripping ratio, meaning less waste material must be removed to access ore deposits, whereas deep-sea mining eliminates overburden stripping entirely by extracting minerals directly from the seabed. This significant difference in stripping ratios impacts environmental disturbance and operational costs, favoring deep-sea mining for reducing waste removal but introducing challenges related to underwater ecosystems.

Remotely Operated Underwater Vehicles (ROVs)

Remotely Operated Underwater Vehicles (ROVs) play a crucial role in deep-sea mining by enabling precise exploration, monitoring, and extraction of mineral resources in extreme underwater environments inaccessible to conventional mining equipment. Unlike traditional mining methods that rely on surface or terrestrial machinery, ROVs offer enhanced maneuverability and real-time data acquisition, optimizing operational efficiency and environmental management in deep-sea mining operations.

Resource Geomatics Mapping

Conventional mining relies heavily on terrestrial surveying techniques and geospatial data integration for accurate resource geomatics mapping, enabling precise land-based resource extraction. Deep-sea mining employs advanced sonar imaging and remote sensing technologies to create high-resolution geomatic maps of underwater mineral deposits, facilitating the exploration of polymetallic nodules and sulfide-rich seafloor sites.

Tailings Plume Dispersion

Tailings plume dispersion in conventional mining typically occurs on land, causing localized soil and water contamination, whereas deep-sea mining releases tailings directly into the ocean, resulting in widespread sediment disturbances and potential harm to marine ecosystems. Studies show that deep-sea tailings plumes can spread over hundreds of square kilometers, affecting benthic biodiversity and altering nutrient cycles in the deep ocean.

In Situ Resource Assessment

Conventional mining relies on extensive geological surveys and core sampling to perform in situ resource assessment on terrestrial ore deposits, enabling precise estimation of mineral quantities and quality. Deep-sea mining faces greater challenges in in situ assessment due to limited access and technology constraints, often relying on remotely operated vehicles (ROVs) and sonar mapping to evaluate polymetallic nodules and sulfide deposits on the ocean floor.

Adaptive Mining Robotics

Adaptive mining robotics in conventional mining enhances operational efficiency and worker safety by automating tasks in variable underground environments. In deep-sea mining, these advanced robotics are equipped with pressure-resistant materials and AI-driven navigation to manage complex seabed terrain and maximize resource extraction.

Conventional Mining vs Deep-Sea Mining Infographic

industrydif.com

industrydif.com