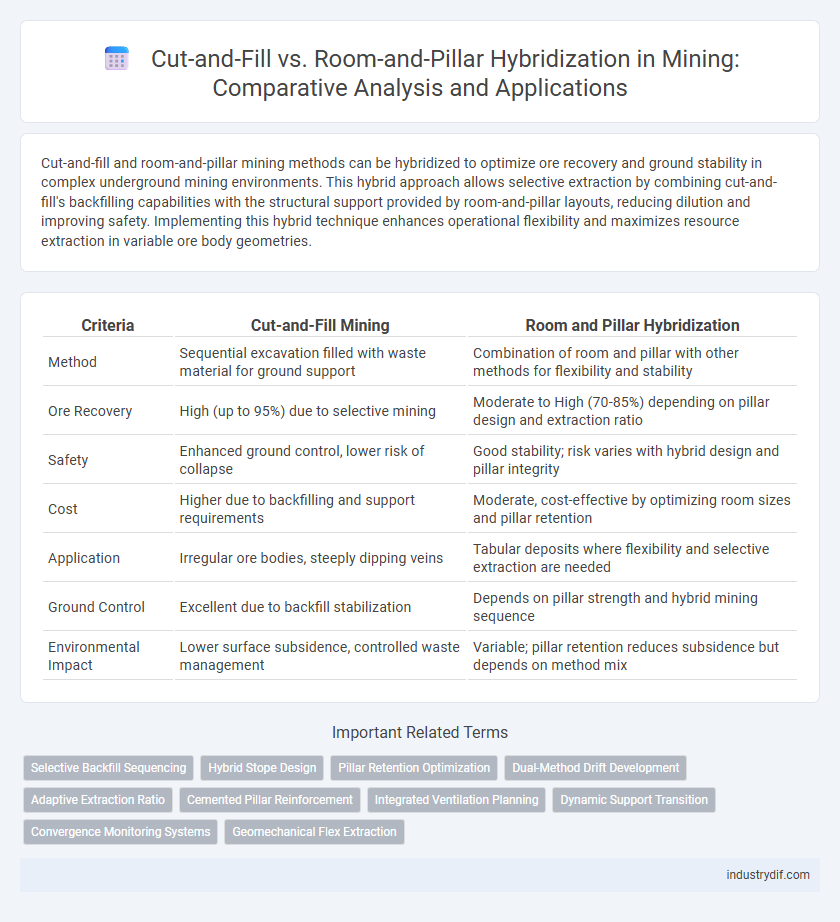

Cut-and-fill and room-and-pillar mining methods can be hybridized to optimize ore recovery and ground stability in complex underground mining environments. This hybrid approach allows selective extraction by combining cut-and-fill's backfilling capabilities with the structural support provided by room-and-pillar layouts, reducing dilution and improving safety. Implementing this hybrid technique enhances operational flexibility and maximizes resource extraction in variable ore body geometries.

Table of Comparison

| Criteria | Cut-and-Fill Mining | Room and Pillar Hybridization |

|---|---|---|

| Method | Sequential excavation filled with waste material for ground support | Combination of room and pillar with other methods for flexibility and stability |

| Ore Recovery | High (up to 95%) due to selective mining | Moderate to High (70-85%) depending on pillar design and extraction ratio |

| Safety | Enhanced ground control, lower risk of collapse | Good stability; risk varies with hybrid design and pillar integrity |

| Cost | Higher due to backfilling and support requirements | Moderate, cost-effective by optimizing room sizes and pillar retention |

| Application | Irregular ore bodies, steeply dipping veins | Tabular deposits where flexibility and selective extraction are needed |

| Ground Control | Excellent due to backfill stabilization | Depends on pillar strength and hybrid mining sequence |

| Environmental Impact | Lower surface subsidence, controlled waste management | Variable; pillar retention reduces subsidence but depends on method mix |

Introduction to Mining Extraction Methods

Cut-and-fill and room-and-pillar hybridization combines the selective ore extraction of cut-and-fill mining with the structural stability of room-and-pillar methods, optimizing both safety and resource recovery in underground mining. This hybrid approach enhances mine design flexibility by allowing selective filling of mined-out areas to support roof integrity while maintaining open pillars to facilitate ore extraction and ventilation. Integrating these methods improves ore recovery rates, reduces ground subsidence risks, and maximizes operational efficiency in variable ore body geometries.

Overview of Cut-and-Fill Mining Technique

Cut-and-fill mining is a selective underground mining method where ore is excavated in horizontal slices, and the voids are progressively backfilled with waste or tailings to provide ground support. This technique enhances safety and ore recovery by maintaining stability in weak or irregular ore bodies, allowing access to narrow or steeply dipping veins. Its adaptability to complex geology makes cut-and-fill a preferred method in hybrid mining systems combining room-and-pillar techniques.

Fundamentals of Room and Pillar Mining

Room and pillar mining fundamentally involves excavating a series of rooms while leaving pillars of untouched ore to support the roof, ensuring stability and safety. This method maximizes ore recovery by balancing extraction with ground control, minimizing subsidence risks. When hybridized with cut-and-fill techniques, the approach enhances flexibility in ore extraction and ground support in variable geotechnical conditions.

Hybridization: Combining Cut-and-Fill and Room and Pillar

Hybridization of cut-and-fill and room-and-pillar mining techniques maximizes ore recovery while enhancing ground stability in irregular ore bodies. This method integrates the selective extraction and backfilling of cut-and-fill with the structural support of room-and-pillar, reducing dilution and improving safety. Optimizing ventilation and operational efficiency becomes possible through tailored design parameters in the combined approach.

Geotechnical Considerations in Hybrid Mining

Cut-and-fill and room and pillar hybridization combines selective ore extraction with strategic ground support to optimize stability in variable geotechnical environments. This method addresses ground control challenges by balancing pillar integrity and backfill strength, minimizing subsidence and seismic risks in weak rock masses. Proper geotechnical assessment, including in-situ stress measurements and rock mass characterization, is critical for designing effective support systems and maximizing resource recovery.

Economic Impacts of Hybrid Mining Approaches

Cut-and-fill and room-and-pillar hybrid mining approaches optimize ore recovery while reducing dilution and ground support costs, directly improving operational economics. This hybrid method enhances ore extraction efficiency, leading to higher metal yield per ton and lowered processing expenses, positively impacting net cash flow. Investment in hybrid systems often results in lower capital expenditure due to optimized mine design and reduced ventilation and backfill requirements.

Safety Aspects of Hybrid Mining Methods

Hybrid mining methods combining cut-and-fill and room and pillar techniques enhance underground safety by providing improved ground support and controlled excavation sequences. The cut-and-fill approach allows precise backfilling to minimize ground movement, while room and pillar elements maintain structural stability by leaving load-bearing pillars. This hybridization reduces risks of collapse, improves ventilation pathways, and facilitates safer worker access within excavated zones.

Ore Recovery and Dilution in Hybrid Systems

Cut-and-fill and room-and-pillar hybrid mining techniques combine to optimize ore recovery by exploiting the selective extraction capabilities of cut-and-fill with the structural stability of room-and-pillar. This hybrid approach significantly reduces dilution by minimizing waste rock mixing and controlling backfill placement, enhancing overall ore grade purity. Improved ore recovery rates in hybrid systems typically range from 85% to 95%, while dilution can be controlled below 10%, maximizing economic efficiency in complex ore bodies.

Technological Innovations in Hybrid Mining

Technological innovations in cut-and-fill and room-and-pillar hybrid mining have enabled enhanced ore recovery and improved ground stability through advanced automation and real-time monitoring systems. Integration of sensor-based equipment and AI-driven planning tools optimizes excavation sequences, reducing dilution and increasing safety. These advancements facilitate adaptive mine designs that maximize productivity while mitigating operational risks in complex geological conditions.

Future Trends in Hybrid Cut-and-Fill and Room and Pillar Mining

Future trends in hybrid Cut-and-Fill and Room and Pillar mining emphasize integrating automation and real-time monitoring systems to enhance safety and operational efficiency. Advanced data analytics and machine learning optimize ore extraction sequences, reducing dilution and improving resource recovery. The adoption of electric and battery-powered equipment further supports sustainable mining practices by lowering emissions in underground environments.

Related Important Terms

Selective Backfill Sequencing

Selective backfill sequencing in cut-and-fill versus room and pillar hybridization enhances ore recovery by precisely controlling stope stability and minimizing dilution. This method strategically schedules backfilling to maintain ground support while optimizing extraction rates in complex vein or tabular deposits.

Hybrid Stope Design

Hybrid stope design in mining leverages the stability and flexibility of cut-and-fill methods combined with the efficiency and bulk extraction capabilities of room and pillar systems, optimizing ore recovery while maintaining ground control. This approach enhances operational safety and economic viability by adapting to varying ore body geometries and geotechnical conditions.

Pillar Retention Optimization

Pillar retention optimization in cut-and-fill versus room and pillar hybridization enhances mine stability and maximizes resource recovery by strategically balancing ground support with extraction efficiency. Employing advanced geotechnical modeling and real-time monitoring ensures optimal pillar sizing, reducing dilution and minimizing seismic risks in underground mining operations.

Dual-Method Drift Development

Dual-method drift development integrates cut-and-fill and room-and-pillar mining techniques to maximize ore recovery while maintaining ground stability in variable ore bodies. This hybrid approach optimizes resource extraction by utilizing cut-and-fill for irregular ore zones and room-and-pillar for consistent sections, reducing dilution and improving safety during underground drift excavation.

Adaptive Extraction Ratio

Adaptive extraction ratio in Cut-and-fill versus Room and Pillar hybridization optimizes ore recovery by dynamically balancing ground stability and ore preservation. This approach adjusts the extraction ratio based on real-time geotechnical data, enhancing safety and maximizing resource efficiency in complex underground mining environments.

Cemented Pillar Reinforcement

Cut-and-fill mining paired with room and pillar methods enhances ore recovery by integrating cemented pillar reinforcement to stabilize excavations, improve ground control, and extend pillar life. Cemented pillars, formed by injecting cementitious grout into voids, increase load-bearing capacity and reduce deformation, enabling safer, more efficient hybridized mining operations.

Integrated Ventilation Planning

Cut-and-fill mining combined with room and pillar hybridization requires integrated ventilation planning to ensure effective airflow distribution, minimizing hazardous gas accumulation and enhancing worker safety in complex underground geometries. Optimizing ventilation networks through computational fluid dynamics (CFD) models supports dynamic airflow adjustments, improving air quality and operational efficiency in hybrid mining environments.

Dynamic Support Transition

Dynamic support transition in cut-and-fill versus room-and-pillar hybridization enhances ground stability by adapting support systems to variable geomechanical conditions, optimizing resource extraction and minimizing deformation risks. Integrating flexible ground control technologies enables real-time reinforcement adjustments, improving safety and operational efficiency in complex underground mining environments.

Convergence Monitoring Systems

Cut-and-fill and room-and-pillar hybridization integrates Convergence Monitoring Systems to enhance ground stability by continuously tracking deformation and convergence within underground openings. This real-time data enables proactive support adjustments, reducing collapse risks and optimizing mine safety and productivity.

Geomechanical Flex Extraction

Cut-and-fill and room-and-pillar hybridization in geomechanical Flex Extraction optimizes ore recovery while maintaining ground stability by combining selective void-filling with systematic pillar support. This method enhances flexibility in ground control strategies, reducing dilution and improving safety in complex mining conditions.

Cut-and-fill vs Room and pillar hybridization Infographic

industrydif.com

industrydif.com