Drill and blast remains the traditional method for rock fragmentation in mining, offering high penetration and cost-effective breaking of hard rock formations. Electric pulse fragmentation employs high-voltage electrical discharges to fracture rock, reducing vibrations and environmental impact compared to conventional blasting. This innovative technique enhances precision and safety while minimizing damage to surrounding structures and groundwater contamination.

Table of Comparison

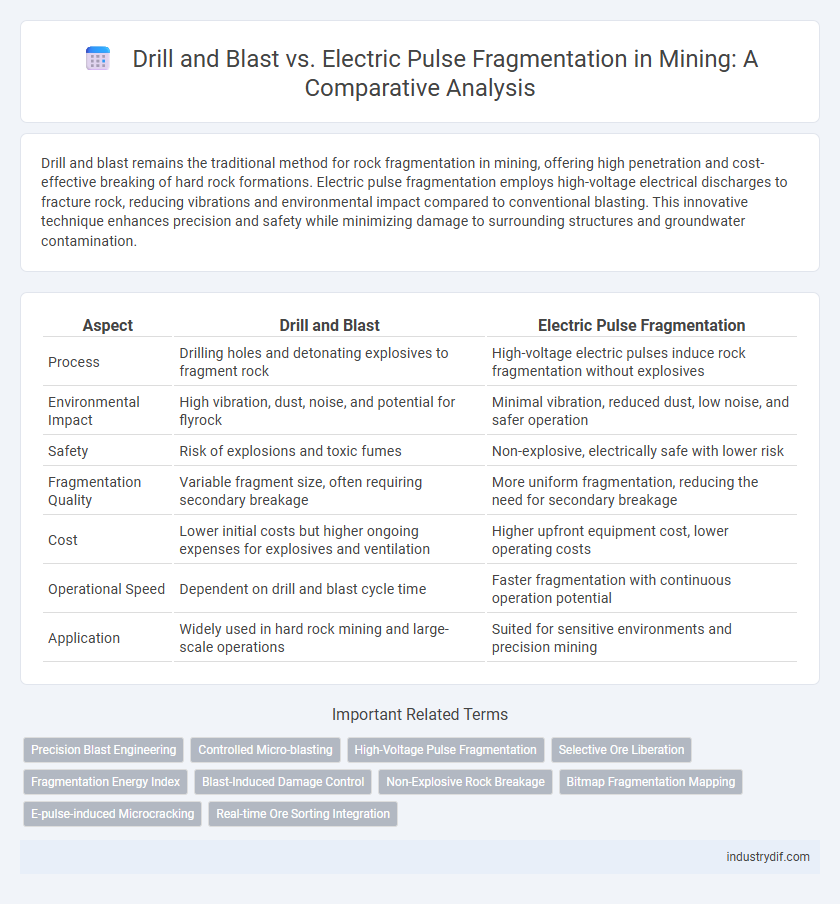

| Aspect | Drill and Blast | Electric Pulse Fragmentation |

|---|---|---|

| Process | Drilling holes and detonating explosives to fragment rock | High-voltage electric pulses induce rock fragmentation without explosives |

| Environmental Impact | High vibration, dust, noise, and potential for flyrock | Minimal vibration, reduced dust, low noise, and safer operation |

| Safety | Risk of explosions and toxic fumes | Non-explosive, electrically safe with lower risk |

| Fragmentation Quality | Variable fragment size, often requiring secondary breakage | More uniform fragmentation, reducing the need for secondary breakage |

| Cost | Lower initial costs but higher ongoing expenses for explosives and ventilation | Higher upfront equipment cost, lower operating costs |

| Operational Speed | Dependent on drill and blast cycle time | Faster fragmentation with continuous operation potential |

| Application | Widely used in hard rock mining and large-scale operations | Suited for sensitive environments and precision mining |

Introduction to Drill and Blast and Electric Pulse Fragmentation

Drill and blast is a traditional mining method involving drilling holes into rock and detonating explosives to fragment the material for easier extraction and transport. Electric pulse fragmentation uses high-voltage electrical pulses to induce cracks and break rock with less vibration and environmental impact. Both techniques are critical in mining operations, with drill and blast widely adopted for its efficiency on hard rock, while electric pulse fragmentation offers a more controlled and sustainable alternative.

Historical Development of Rock Breakage Techniques

Drill and blast technology, developed in the late 19th century, revolutionized mining by enabling efficient fragmentation of hard rock using explosives, becoming the industry standard for decades. Electric pulse fragmentation, emerging in the early 21st century, utilizes high-voltage electric discharges to induce micro-fractures in rock, offering a safer and more environmentally friendly alternative. Advances in electric pulse technology address limitations of traditional drilling methods, promoting reduced vibration, lower energy consumption, and minimized environmental impact in modern mining operations.

Principles of Drill and Blast Operations

Drill and blast operations rely on precise drilling patterns and controlled explosive charges to fragment rock, enabling efficient extraction in mining projects. The process involves creating intersecting holes drilled into the rock face, followed by the strategic placement of explosives that generate controlled fractures upon detonation. This method optimizes rock fragmentation size for easier handling and transportation, distinguishing it from emerging technologies like electric pulse fragmentation which use high-energy electrical discharges for rock breakage.

Fundamentals of Electric Pulse Fragmentation Technology

Electric pulse fragmentation technology uses high-voltage electric discharges to create stress waves that fracture rock, minimizing vibrations and reducing environmental impact compared to traditional drill and blast methods. This technology enhances precision by targeting rock breakage at the molecular level, leading to improved fragmentation and easier material handling. Energy efficiency and reduced maintenance costs make electric pulse fragmentation a compelling alternative for sustainable mining operations.

Efficiency and Productivity Comparison

Drill and blast methods in mining typically offer high fragmentation rates but generate significant vibration and environmental impact, leading to downtime and lower overall efficiency. Electric pulse fragmentation provides precise rock breakage with reduced vibrations and minimal environmental disturbance, enhancing productivity through faster drilling cycles and less secondary breakage. Studies show electric pulse technology can increase operational efficiency by up to 30%, reducing costs associated with drilling, blasting, and material handling.

Environmental Impact and Sustainability

Electric pulse fragmentation significantly reduces environmental impact by minimizing vibration, noise, and dust emissions compared to traditional drill and blast methods. This innovative technology lowers greenhouse gas emissions and energy consumption, promoting sustainable mining practices. Adoption of electric pulse fragmentation enhances operational safety and aligns with global sustainability goals by mitigating ecosystem disruption and improving resource efficiency.

Safety Considerations in Both Methods

Drill and blast methods pose significant safety risks including flyrock, vibrations, and explosive handling hazards, requiring stringent protocols and protective equipment. Electric pulse fragmentation offers enhanced safety by minimizing airborne contaminants, vibrations, and eliminating the need for explosives, thus reducing the risk of accidents and health issues. Both methods demand comprehensive risk assessments and training, but electric pulse fragmentation provides a safer work environment through advanced technology and reduced reliance on hazardous materials.

Cost Analysis: Initial Investment and Operational Expenses

Drill and blast methods require significant initial investment in drilling equipment, explosives, and safety infrastructure, alongside high operational expenses due to explosive materials and personnel safety protocols. Electric pulse fragmentation involves a higher upfront cost for advanced pulse generators and specialized maintenance systems but reduces operational expenses by minimizing explosive consumption and improving energy efficiency. Comparative cost analysis reveals electric pulse fragmentation offers long-term savings through lower material costs and enhanced productivity despite a steeper initial financial commitment.

Case Studies: Real-World Applications

Case studies demonstrate that drill and blast techniques remain dominant in large-scale mining projects due to their cost-effectiveness and adaptability to various rock types. Electric pulse fragmentation shows promising results in precision control and reduced environmental impact, with successful applications in sensitive underground mining environments. Comparative analyses highlight electric pulse technology's potential to lower vibration and dust levels, improving safety and operational efficiency in specific scenarios.

Future Prospects and Innovations in Rock Fragmentation

Electric pulse fragmentation represents a breakthrough in rock fragmentation technology with future prospects emphasizing reduced environmental impact and improved energy efficiency compared to traditional drill and blast methods. Innovations in electric pulse systems focus on precision targeting, minimizing vibrations, and enhancing fragmentation quality, which can lead to safer operations and lower operational costs in mining projects. Ongoing research in integrating real-time monitoring and automation aims to optimize the fragmentation process, making electric pulse technology a promising alternative for sustainable mining practices.

Related Important Terms

Precision Blast Engineering

Precision Blast Engineering enhances drill and blast operations by optimizing explosive placement and timing to achieve controlled fragmentation and minimize ground vibrations, thereby improving overall safety and ore recovery. Electric pulse fragmentation utilizes high-voltage pulses to induce rock fracturing with minimal environmental impact, offering a precise alternative that reduces explosive use and enhances fragmentation consistency in sensitive mining environments.

Controlled Micro-blasting

Controlled micro-blasting in drill and blast techniques enhances fragmentation precision by optimizing energy distribution and minimizing overbreak, improving safety and reducing environmental impact. Electric pulse fragmentation offers an alternative method that leverages high-voltage pulses to induce rock breakage with minimal vibration and dust, but controlled micro-blasting remains preferred for its established operational control and cost-effectiveness in complex mining conditions.

High-Voltage Pulse Fragmentation

High-Voltage Pulse Fragmentation (HVPF) offers a precise, environmentally friendly alternative to traditional drill and blast methods by using controlled electric pulses to induce fractures in rock formations without explosive charges. This technique enhances fragmentation efficiency, reduces ground vibration and dust emissions, and lowers operational costs in mining operations compared to conventional blasting.

Selective Ore Liberation

Drill and blast techniques create larger fragmented rock, often resulting in mixed ore and waste that complicates selective ore liberation. Electric pulse fragmentation offers precise breakage by targeting specific mineral boundaries, enhancing selective ore liberation and reducing dilution in mining operations.

Fragmentation Energy Index

Drill and blast methods typically feature a higher Fragmentation Energy Index (FEI) due to the explosive energy required to break rock, whereas electric pulse fragmentation offers a lower FEI by utilizing controlled electrical discharges for precise rock breakage. This reduction in fragmentation energy with electric pulse technology results in decreased environmental impact and improved energy efficiency in mining operations.

Blast-Induced Damage Control

Drill and blast techniques often cause extensive blast-induced damage, including overbreak and fragmentation variability, which can compromise rock stability and increase downstream processing costs. Electric pulse fragmentation offers precise control over fracture propagation, significantly reducing blast-induced damage while optimizing fragmentation and minimizing environmental impact in mining operations.

Non-Explosive Rock Breakage

Drill and blast remains the dominant method for rock fragmentation in mining, leveraging controlled explosives to fracture hard rock efficiently, while electric pulse fragmentation offers a non-explosive alternative by utilizing high-voltage electrical discharges to induce rock breakage with reduced vibration and environmental impact. Electric pulse fragmentation enhances safety and precision in sensitive or urban mining areas by minimizing ground disturbance and eliminating explosive hazards.

Bitmap Fragmentation Mapping

Bitmap Fragmentation Mapping in drill and blast operations enables precise analysis of fragmentation patterns by capturing high-resolution images that quantify fragment size distribution, improving blast design and optimization. Electric pulse fragmentation offers a non-explosive alternative with enhanced control over rock breakage, but Bitmap Fragmentation Mapping remains critical for comparing efficacy and refining fragmentation outcomes in both methods.

E-pulse-induced Microcracking

E-pulse-induced microcracking enhances rock breakage by generating controlled fractures at the microscopic level, which improves fragmentation efficiency compared to traditional drill and blast methods. This technique reduces explosive consumption and vibration, leading to safer and more environmentally friendly mining operations.

Real-time Ore Sorting Integration

Drill and blast techniques produce fragmented ore but often generate inconsistent particle sizes, complicating real-time ore sorting integration and reducing processing efficiency. Electric pulse fragmentation enhances fragmentation precision with less vibration, enabling more accurate real-time ore sorting systems to optimize recovery rates and reduce processing costs.

Drill and blast vs Electric pulse fragmentation Infographic

industrydif.com

industrydif.com