Drill and blast techniques offer precise control over rock fragmentation, making them suitable for hard rock mining and complex geological conditions. Mechanical rock excavation provides continuous operation, reducing cycle times and enhancing safety by minimizing explosive use. Choosing between these methods depends on factors such as rock hardness, project scale, and environmental impact considerations.

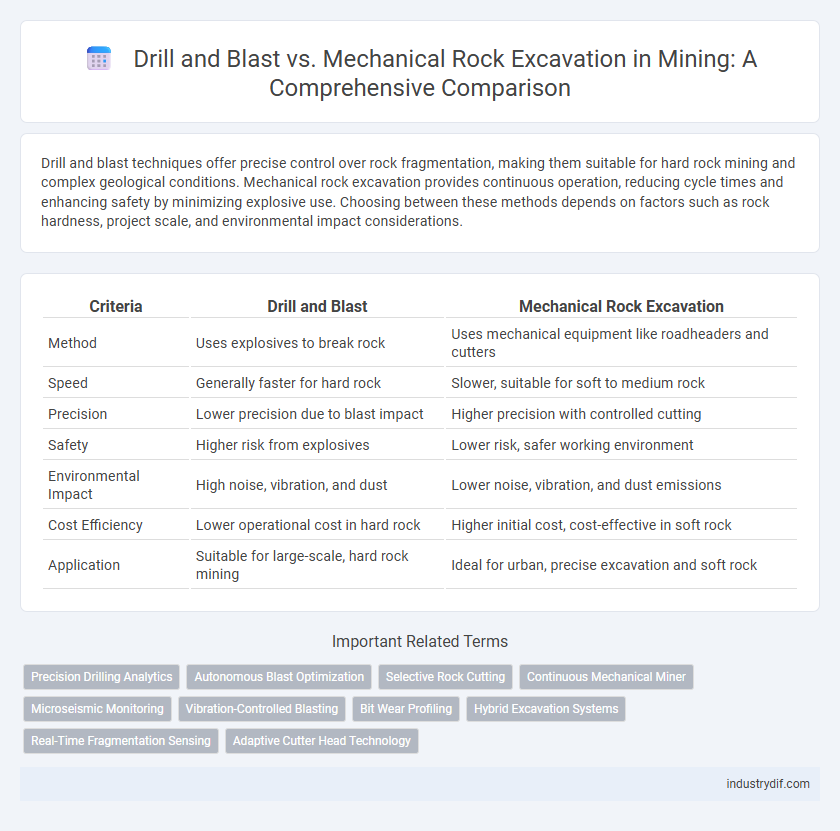

Table of Comparison

| Criteria | Drill and Blast | Mechanical Rock Excavation |

|---|---|---|

| Method | Uses explosives to break rock | Uses mechanical equipment like roadheaders and cutters |

| Speed | Generally faster for hard rock | Slower, suitable for soft to medium rock |

| Precision | Lower precision due to blast impact | Higher precision with controlled cutting |

| Safety | Higher risk from explosives | Lower risk, safer working environment |

| Environmental Impact | High noise, vibration, and dust | Lower noise, vibration, and dust emissions |

| Cost Efficiency | Lower operational cost in hard rock | Higher initial cost, cost-effective in soft rock |

| Application | Suitable for large-scale, hard rock mining | Ideal for urban, precise excavation and soft rock |

Introduction to Drill and Blast vs Mechanical Rock Excavation

Drill and blast is a traditional mining method involving drilling holes into rock, filling them with explosives, and detonating to fragment the material for removal. Mechanical rock excavation employs machinery such as roadheaders, continuous miners, or tunnel boring machines to break and remove rock without explosives. Each method offers distinct advantages depending on factors like rock type, excavation size, safety considerations, and environmental impact.

Overview of Drill and Blast Method

The drill and blast method remains a fundamental technique in mining, involving precise drilling of holes followed by the controlled detonation of explosives to fragment rock. This approach offers flexibility in varying rock conditions and is widely used in both surface and underground mining operations. Its effectiveness in breaking hard rock efficiently supports optimal excavation rates and cost management compared to mechanical rock excavation methods.

Overview of Mechanical Rock Excavation

Mechanical rock excavation employs advanced equipment such as continuous miners, roadheaders, and tunnel boring machines to efficiently break and remove rock without the need for explosives. This method enhances safety by reducing vibration, dust, and fly rock hazards typically associated with drill and blast techniques. Mechanical excavation offers precise control, faster cycle times, and lower environmental impact, making it suitable for urban mining operations and complex geological conditions.

Comparative Analysis: Efficiency and Productivity

Drill and blast techniques offer high fragmentation and flexibility in various rock conditions, leading to faster cycle times in hard rock mining compared to mechanical rock excavation methods. Mechanical rock excavation, such as roadheaders and continuous miners, provides greater precision and reduced vibration, enhancing safety and minimizing damage to surrounding structures, but often operates at slower advance rates in very hard rock. Efficiency in drill and blast is typically higher in large-scale, hard rock operations, while mechanical excavation is more productive in softer formations and underground projects requiring controlled excavation.

Cost Considerations in Mining Operations

Drill and blast methods in mining typically incur lower upfront equipment costs but involve higher expenses related to explosives, labor, and vibration control measures. Mechanical rock excavation demands significant capital investment in advanced machinery such as roadheaders and continuous miners, yet reduces costs associated with blasting, ground vibration mitigation, and ventilation. Cost efficiency in mining operations depends on factors like orebody characteristics, project scale, and local regulatory compliance related to safety and environmental impact.

Environmental Impact Assessment

Drill and blast methods generate significant dust, vibrations, and noise, contributing to air and noise pollution while posing risks to nearby ecosystems. Mechanical rock excavation produces fewer emissions and reduces ground vibrations, minimizing disturbance to surrounding habitats and improving environmental compliance. Comparative assessments reveal mechanical techniques often result in lower carbon footprints and enhanced sustainability in mining operations.

Safety Standards and Risk Management

Drill and blast techniques in mining carry significant risks, including flyrock, vibration, and dust hazards, requiring stringent safety standards and comprehensive risk management protocols such as precise blast design and exclusion zones. Mechanical rock excavation, utilizing equipment like roadheaders and continuous miners, offers improved safety by reducing exposure to explosives and minimizing airborne hazards, although it demands rigorous maintenance and operator training to prevent mechanical failures. Both methods necessitate adherence to occupational health and safety regulations, but mechanical excavation often achieves higher safety compliance through controlled operations and real-time monitoring systems.

Equipment and Technology Requirements

Drill and blast methods require specialized drilling rigs, explosive handling equipment, and precise blast design software to optimize fragmentation and minimize vibration. Mechanical rock excavation relies on advanced continuous miners, roadheaders, and hydraulic breakers, demanding robust machinery capable of operating in confined spaces with high precision. Both methods depend on cutting-edge technology integration, but mechanical excavation emphasizes automation and real-time monitoring systems to enhance safety and efficiency.

Application Suitability by Rock Type

Drill and blast methods excel in hard, massive rock formations such as granite and basalt, where controlled explosive energy efficiently fractures the rock. Mechanical rock excavation is better suited for softer, less consolidated materials like limestone and shale, enabling continuous excavation without the risks associated with blasting. Selection depends on rock hardness, fracturing characteristics, and environmental constraints, optimizing productivity and safety.

Future Trends in Rock Excavation Methods

Emerging trends in rock excavation prioritize automation and sustainability, with drill and blast methods integrating digital technologies for precision and reduced environmental impact. Mechanical rock excavation advances focus on continuous mining equipment and robotics, enhancing safety and operational efficiency in complex ore bodies. Hybrid systems combining explosive techniques and mechanical tools are gaining traction to optimize productivity and minimize fragmentation issues.

Related Important Terms

Precision Drilling Analytics

Precision drilling analytics significantly enhance drill and blast operations by delivering real-time data on rock properties and drill bit performance, enabling optimized blast patterns and reducing overbreak. Mechanical rock excavation benefits less from such analytics due to its continuous cutting method, which offers lower precision in rock fragmentation control compared to advanced drill and blast with precision drilling technologies.

Autonomous Blast Optimization

Autonomous Blast Optimization enhances drilling and blasting by utilizing AI-driven data analysis and real-time monitoring to maximize fragmentation efficiency while reducing costs and environmental impact. In contrast, mechanical rock excavation offers precision and reduced vibration but lacks the adaptive optimization capabilities that autonomous blast systems provide for improving overall mine productivity.

Selective Rock Cutting

Drill and blast techniques enable precise selective rock cutting by creating controlled fractures that target specific ore bodies, minimizing damage to surrounding rock and improving ore recovery rates. Mechanical rock excavation offers continuous selective cutting with advanced cutters and sensors, enhancing accuracy and safety while reducing vibration and environmental impact in mining operations.

Continuous Mechanical Miner

Continuous mechanical miners offer higher operational efficiency and safety compared to traditional drill and blast methods by eliminating explosives and enabling precise, continuous rock cutting. This technology enhances productivity in underground mining with reduced vibration, dust, and overall environmental impact, making it the preferred choice for soft to medium-hard rock formations.

Microseismic Monitoring

Microseismic monitoring in drill and blast operations provides critical data on rock fragmentation and vibration control, enhancing safety and optimizing blast designs. Mechanical rock excavation, while producing fewer vibrations, benefits from integrated microseismic sensors to monitor rock stability and detect potential failure zones in real-time.

Vibration-Controlled Blasting

Vibration-controlled blasting in mining reduces ground vibrations compared to traditional drill and blast methods, minimizing damage to surrounding rock structures and infrastructure. Mechanical rock excavation offers lower vibration levels but may have limited application in hard rock environments where controlled blasting remains crucial for efficiency and safety.

Bit Wear Profiling

Bit wear profiling in drill and blast methods significantly influences operational efficiency by determining penetration rates and maintenance schedules, while mechanical rock excavation relies on continuous monitoring of bit degradation to optimize cutter replacement and reduce downtime. Analyzing wear patterns through advanced sensor technologies enhances predictive maintenance strategies in both techniques, maximizing productivity and minimizing costs in mining operations.

Hybrid Excavation Systems

Hybrid excavation systems combine drill and blast techniques with mechanical rock excavation to enhance efficiency and reduce operational costs in mining projects. Integrating hydraulic rock breakers and advanced drilling equipment enables higher precision, minimized rock damage, and improved fragmentation control compared to traditional methods.

Real-Time Fragmentation Sensing

Real-time fragmentation sensing enhances drill and blast operations by providing immediate feedback on rock breakage, optimizing blast design and reducing overbreak risks. Mechanical rock excavation, while efficient in continuous operations, lacks the same granularity in fragmentation control, making real-time sensing technologies critical for improving downstream processing efficiency.

Adaptive Cutter Head Technology

Adaptive Cutter Head Technology in mechanical rock excavation enhances efficiency by dynamically adjusting cutting parameters to optimize rock fragmentation and reduce wear, outperforming traditional drill and blast methods in precision and environmental impact. This technology enables continuous excavation with real-time feedback, minimizing vibrations and improving safety compared to the intermittent and high-impact nature of drill and blast operations.

Drill and blast vs Mechanical rock excavation Infographic

industrydif.com

industrydif.com