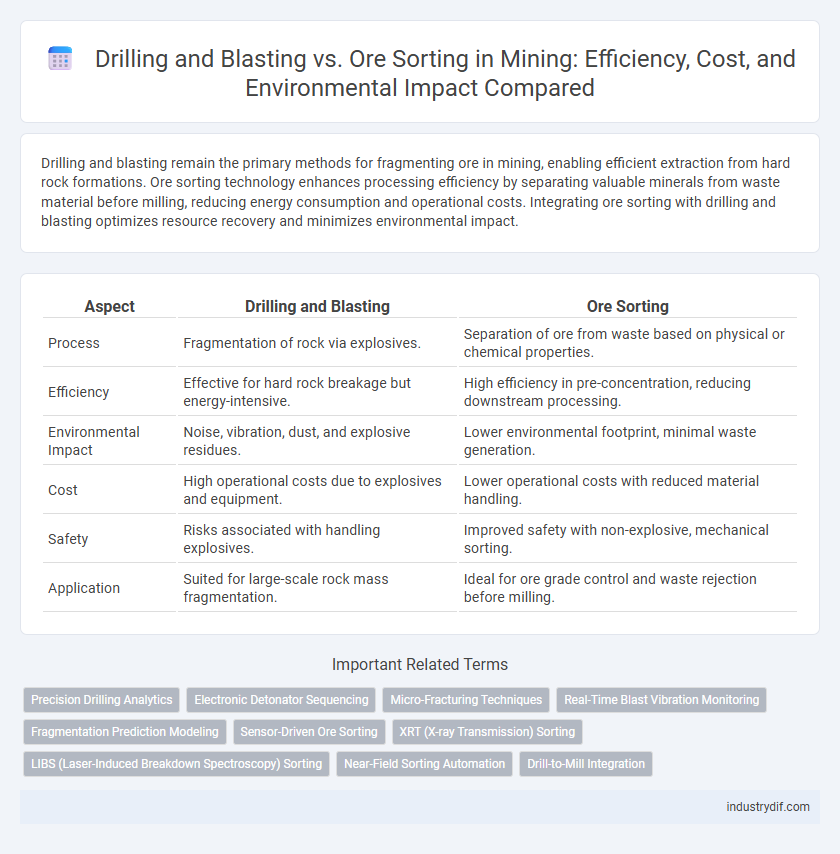

Drilling and blasting remain the primary methods for fragmenting ore in mining, enabling efficient extraction from hard rock formations. Ore sorting technology enhances processing efficiency by separating valuable minerals from waste material before milling, reducing energy consumption and operational costs. Integrating ore sorting with drilling and blasting optimizes resource recovery and minimizes environmental impact.

Table of Comparison

| Aspect | Drilling and Blasting | Ore Sorting |

|---|---|---|

| Process | Fragmentation of rock via explosives. | Separation of ore from waste based on physical or chemical properties. |

| Efficiency | Effective for hard rock breakage but energy-intensive. | High efficiency in pre-concentration, reducing downstream processing. |

| Environmental Impact | Noise, vibration, dust, and explosive residues. | Lower environmental footprint, minimal waste generation. |

| Cost | High operational costs due to explosives and equipment. | Lower operational costs with reduced material handling. |

| Safety | Risks associated with handling explosives. | Improved safety with non-explosive, mechanical sorting. |

| Application | Suited for large-scale rock mass fragmentation. | Ideal for ore grade control and waste rejection before milling. |

Overview of Drilling and Blasting Techniques

Drilling and blasting techniques involve creating precise drill patterns to fracture rock for efficient ore extraction, using controlled explosives tailored to rock type and deposit characteristics. Various methods such as rotary drilling, percussion drilling, and directional drilling optimize fragmentation, reduce energy consumption, and enhance safety in mining operations. These techniques are fundamental in preparing ore for subsequent processing stages, contrasting with ore sorting which focuses on post-extraction material separation.

Fundamentals of Ore Sorting Technology

Ore sorting technology employs advanced sensors to distinguish ore from waste based on physical and chemical properties, significantly enhancing mining efficiency and reducing processing costs. Unlike traditional drilling and blasting, which mechanically break rock without selective separation, ore sorting enables immediate segregation of valuable minerals before crushing, minimizing material handling and downstream energy consumption. Fundamental sorting methods include X-ray transmission, near-infrared, and optical sensors, each optimized to detect specific ore characteristics for precise separation at early stages of mining operations.

Key Differences Between Drilling & Blasting and Ore Sorting

Drilling and blasting involve breaking rock through controlled explosions to facilitate material extraction, while ore sorting separates valuable minerals from waste rock using sensor-based technologies before processing. Drilling and blasting impact productivity by increasing fragmentation size and enabling easier hauling, whereas ore sorting improves efficiency by reducing the volume of material sent for crushing and milling. The environmental footprint differs significantly; drilling and blasting generate dust, vibration, and noise, whereas ore sorting reduces energy consumption and waste generation through selective processing.

Efficiency Comparison: Material Handling and Processing

Drilling and blasting involve fragmenting ore through controlled explosions, enabling bulk handling but often producing variable particle sizes that require extensive crushing and grinding, leading to higher energy consumption. Ore sorting enhances efficiency by pre-concentrating material, rejecting waste rock before processing, which reduces the volume of material handled and lowers energy use in downstream crushing and grinding. This targeted approach in ore sorting optimizes processing efficiency and reduces operational costs compared to the traditional drilling and blasting method.

Environmental Impact: Blasting Residue vs Ore Sorting Waste

Blasting in mining generates significant environmental impact through the dispersion of dust, vibration, and leftover explosive residues that contaminate soil and water sources. Ore sorting reduces waste production by selectively separating ore from waste material early in the process, minimizing the volume of material that undergoes crushing and grinding. This results in lower energy consumption, reduced tailings, and decreased environmental footprint compared to traditional drilling and blasting methods.

Cost Analysis: Operational Expenditure and Capital Investment

Drilling and blasting involve significant operational expenditure due to high fuel consumption, explosives, and labor costs, alongside substantial capital investment in heavy machinery and safety systems. Ore sorting reduces operational costs by minimizing waste processing and energy consumption, requiring lower capital investment in advanced sensor technologies and automation systems. Cost analysis reveals ore sorting as a more efficient solution for reducing long-term expenses, while drilling and blasting remain capital-intensive with ongoing high operational costs.

Safety Considerations in Drilling, Blasting, and Ore Sorting

Drilling and blasting pose significant safety risks including flyrock, vibrations, and toxic gases, requiring strict protocols and protective equipment to mitigate hazards. Ore sorting enhances safety by reducing the volume of material handled, lowering exposure to dust and heavy machinery accidents. Implementing automated ore sorting systems further minimizes human involvement in hazardous zones, promoting a safer mining environment.

Advances in Automation: Smart Drilling and Automated Sorting

Advances in automation have revolutionized mining through the integration of smart drilling systems and automated ore sorting technologies, enhancing precision and efficiency in resource extraction. Smart drilling employs real-time data analytics and machine learning algorithms to optimize blast patterns and reduce operational costs, while automated sorting uses high-resolution sensors and AI-driven classifiers to separate valuable ore from waste with unprecedented accuracy. These technologies collectively improve recovery rates, minimize environmental impact, and streamline the mining process from blast design to material processing.

Application Scenarios: Choosing the Right Method

Drilling and blasting are ideal for large-scale mining operations requiring fragmentation of hard rock and complex ore bodies, offering high productivity in open-pit and underground mines. Ore sorting excels in pre-concentration by selectively separating valuable minerals from waste, enhancing efficiency in deposits with variable grade distribution or low-grade ores. Selecting the right method depends on ore characteristics, deposit geometry, economic factors, and environmental considerations to maximize recovery and minimize operational costs.

Future Trends in Sustainable Mineral Extraction

Drilling and blasting remain prevalent in mineral extraction but face growing scrutiny due to environmental impacts and energy consumption. Ore sorting technology advances offer a sustainable alternative by enhancing ore grade before processing, reducing waste and lowering energy use. Future trends prioritize integrating precise ore sorting with minimal drilling and blasting to optimize resource efficiency and decrease ecological footprints in mining operations.

Related Important Terms

Precision Drilling Analytics

Precision Drilling Analytics enhances drilling and blasting by optimizing drill patterns and explosive placement to improve fragmentation and reduce costs, leading to increased operational efficiency. In contrast, ore sorting leverages sensor-based technology to separate valuable ore from waste before processing, minimizing dilution but relying less on drilling accuracy.

Electronic Detonator Sequencing

Electronic detonator sequencing enhances drilling and blasting precision by enabling controlled, programmable delays, which optimize fragmentation and reduce vibrations. Compared to ore sorting, this technology increases operational efficiency by improving blast outcomes, leading to better ore recovery and reduced downstream processing costs.

Micro-Fracturing Techniques

Micro-fracturing techniques in drilling and blasting enhance rock fragmentation by creating controlled fractures that improve ore breakage and reduce energy consumption. Unlike ore sorting, which separates valuable minerals post-extraction, micro-fracturing optimizes in-situ rock breakage to increase efficiency in downstream ore processing.

Real-Time Blast Vibration Monitoring

Real-time blast vibration monitoring enhances drilling and blasting efficiency by providing immediate data on blast impact, enabling precise control to minimize environmental disruption and maximize ore recovery. Integrating ore sorting technologies further refines material processing by separating valuable ore from waste in real time, optimizing overall mining productivity and reducing processing costs.

Fragmentation Prediction Modeling

Fragmentation prediction modeling enhances drilling and blasting by accurately forecasting fragment size distribution, leading to optimized blast designs and reduced downstream processing costs. Ore sorting utilizes real-time data to improve material separation efficiency, but integrating fragmentation prediction models with ore sorting technologies can further refine grade control and increase overall operational productivity.

Sensor-Driven Ore Sorting

Sensor-driven ore sorting enhances efficiency by rapidly separating valuable minerals from waste using technologies like X-ray transmission and near-infrared sensors, reducing the need for extensive drilling and blasting. This selective approach minimizes environmental impact and operational costs while improving ore grade before downstream processing.

XRT (X-ray Transmission) Sorting

XRT (X-ray Transmission) sorting leverages differences in atomic density to separate ore from waste, enhancing efficiency by reducing the volume of material sent to milling compared to traditional drilling and blasting methods. This technology minimizes dilution and environmental impact by selectively targeting valuable minerals early in the process, optimizing downstream recovery and operational costs.

LIBS (Laser-Induced Breakdown Spectroscopy) Sorting

Laser-Induced Breakdown Spectroscopy (LIBS) sorting in mining enhances ore processing efficiency by providing real-time, high-resolution elemental analysis during sorting, reducing reliance on traditional drilling and blasting methods that often lead to material dilution and environmental impact. LIBS technology enables precise discrimination between valuable minerals and waste rock, optimizing ore grade control and minimizing operational costs compared to conventional blast fragmentation techniques.

Near-Field Sorting Automation

Near-field sorting automation in mining enhances drilling and blasting efficiency by precisely separating ore from waste before extraction, reducing dilution and increasing grade control. Implementing advanced sensor-based ore sorting technologies minimizes unnecessary blasting, lowers operational costs, and optimizes downstream processing.

Drill-to-Mill Integration

Drill-to-Mill Integration enhances mining efficiency by synchronizing drilling, blasting, and ore sorting processes to optimize fragmentation and downstream material handling. This approach reduces energy consumption, improves ore grade control, and increases throughput by ensuring precise blasting tailored to ore characteristics identified through advanced sorting technologies.

Drilling and blasting vs Ore sorting Infographic

industrydif.com

industrydif.com