Drilling provides precise core samples allowing detailed analysis of mineral composition and geology, essential for accurate resource estimation. Blast hole sampling offers rapid data collection over large areas, supporting efficient grade control during mining operations. Choosing between them depends on the desired accuracy, cost, and time constraints of the project.

Table of Comparison

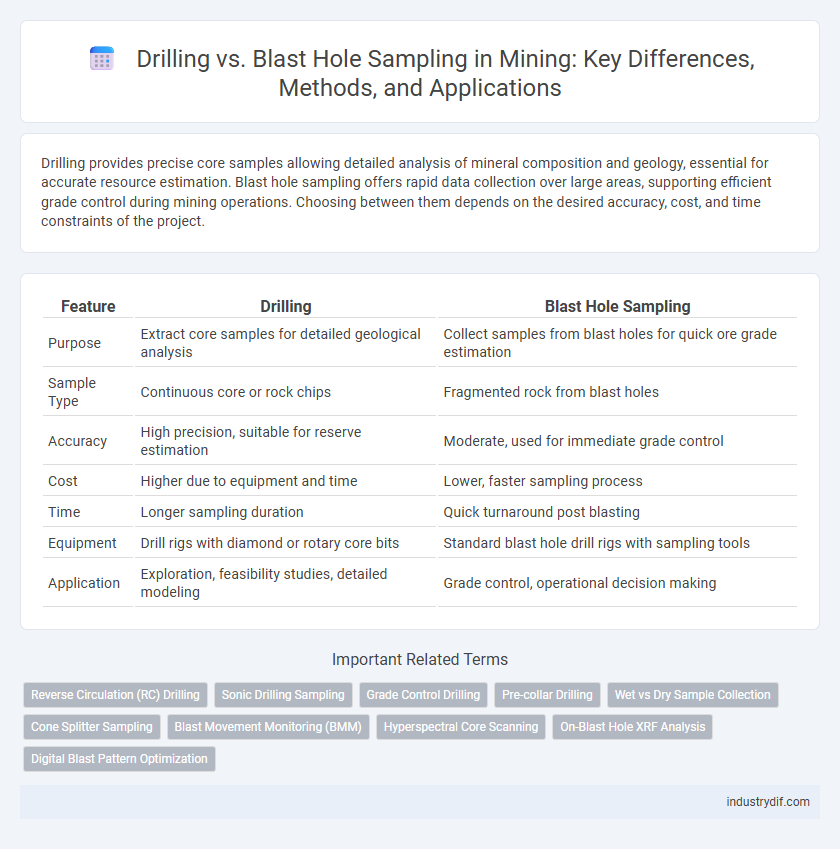

| Feature | Drilling | Blast Hole Sampling |

|---|---|---|

| Purpose | Extract core samples for detailed geological analysis | Collect samples from blast holes for quick ore grade estimation |

| Sample Type | Continuous core or rock chips | Fragmented rock from blast holes |

| Accuracy | High precision, suitable for reserve estimation | Moderate, used for immediate grade control |

| Cost | Higher due to equipment and time | Lower, faster sampling process |

| Time | Longer sampling duration | Quick turnaround post blasting |

| Equipment | Drill rigs with diamond or rotary core bits | Standard blast hole drill rigs with sampling tools |

| Application | Exploration, feasibility studies, detailed modeling | Grade control, operational decision making |

Introduction to Drilling and Blast Hole Sampling in Mining

Drilling in mining involves creating precise boreholes to extract core samples, providing detailed geological information essential for resource estimation and mine planning. Blast hole sampling refers to collecting rock fragments from blast holes after drilling, offering rapid, cost-effective data on ore grade variability. Both methods are critical for accurate mineral resource assessment, influencing operational decision-making and optimizing extraction processes.

Key Differences Between Drilling and Blast Hole Sampling

Drilling provides precise and continuous core samples essential for detailed geological analysis and resource estimation, whereas blast hole sampling collects fragmented rock from explosive drills, offering less detailed but faster bulk samples for grade control. Drilling is typically used for exploration and feasibility studies due to its accuracy, while blast hole sampling supports operational decisions in active mining through rapid, real-time data. The key differences lie in sample quality, data resolution, and application within the mining process.

Purpose and Applications in Mining Operations

Drilling in mining serves primarily to extract core samples for detailed geological analysis, enabling precise resource estimation and mine planning. Blast hole sampling, by contrast, is used to collect fragmented material during drilling for immediate grade control and orebody delineation in blasting operations. Both methods optimize resource evaluation but drilling supports long-term exploration while blast hole sampling focuses on operational grade control.

Equipment Used in Drilling vs Blast Hole Sampling

Drilling employs specialized rigs such as diamond core drills, rotary drills, and sonic drills designed for extracting continuous core samples from deep underground formations. Blast hole sampling relies on drill rigs equipped with larger diameter bits to create holes intended for loading explosives and collecting bulk samples from blasted rock. The equipment in drilling prioritizes precision and minimal disturbance, whereas blast hole sampling tools emphasize efficiency and robust construction to handle abrasive materials and high-volume sampling.

Sampling Techniques: Methods and Best Practices

Drilling sampling involves extracting continuous core or chip samples to provide detailed geological and grade information, ideal for precise ore body characterization. Blast hole sampling uses drill holes drilled for blasting purposes, collecting fragmented material from these holes to estimate grade distribution but may offer less representative samples due to rock breakage variability. Best practices emphasize proper sample collection, preparation, and consistent methodology to ensure reliable assay results and accurate resource estimation.

Data Quality and Reliability in Drilling and Blast Hole Sampling

Drilling delivers higher data quality and reliability than blast hole sampling due to its precise core recovery and intact sample integrity, which ensures accurate geological and grade modeling. Blast hole sampling often encounters contamination and sample dilution, reducing data accuracy and increasing uncertainty in resource estimation. High-fidelity data from drilling underpin more reliable decision-making in mine planning and reserve calculation.

Challenges and Limitations in Sampling Processes

Drilling sampling in mining faces challenges such as core loss, contamination, and equipment wear, which can compromise sample integrity and representativeness. Blast hole sampling encounters limitations including uneven fragmentation, dilution from surrounding rock, and difficulties in obtaining a homogeneous sample due to explosive displacement. Both methods require careful calibration and quality control to mitigate sampling bias and ensure accurate grade estimation.

Cost Considerations: Drilling vs Blast Hole Sampling

Drilling incurs higher upfront costs due to advanced equipment and extensive labor requirements, making it suitable for detailed subsurface analysis in mining projects. Blast hole sampling offers a cost-effective alternative by leveraging existing blast holes for preliminary ore grade estimation, significantly reducing operational expenses. Choosing between drilling and blast hole sampling depends on budget constraints and the level of sampling precision needed for resource evaluation.

Environmental and Safety Aspects

Drilling in mining offers precise sample collection with minimal surface disturbance, reducing environmental impact and ensuring safer working conditions by limiting explosive use. Blast hole sampling involves controlled explosions that pose higher risks of flyrock, dust generation, and ground vibration, which can negatively affect nearby ecosystems and worker safety. Choosing drilling over blast hole sampling enhances environmental protection and minimizes health hazards in mining operations.

Future Trends in Mining Sampling Technologies

Advancements in mining sampling technologies are increasingly favoring automated and real-time data acquisition methods, enhancing the accuracy of blast hole sampling over traditional drilling techniques. Emerging tools like laser-induced breakdown spectroscopy (LIBS) and hyperspectral imaging enable rapid geochemical analysis directly in blast holes, reducing sampling errors and operational downtime. Future trends emphasize integration of AI-driven predictive models with remote sensing data to optimize sampling strategies and improve resource estimation efficiency.

Related Important Terms

Reverse Circulation (RC) Drilling

Reverse Circulation (RC) drilling offers faster, more cost-effective sampling compared to traditional blast hole sampling, providing higher-quality, uncontaminated rock chips for precise grade control in mining operations. Its ability to penetrate hard rock formations with minimal sample dilution makes RC drilling a preferred method for detailed ore body evaluation and resource estimation.

Sonic Drilling Sampling

Sonic drilling sampling offers higher precision and minimal contamination compared to traditional blast hole sampling, making it ideal for extracting detailed geotechnical and mineralogical data. This method uses high-frequency vibrations to penetrate rock, providing continuous core samples that enhance resource evaluation accuracy and reduce operational disturbances.

Grade Control Drilling

Grade control drilling provides precise, spatially defined assays that enable accurate ore boundary delineation, critical for optimizing ore extraction and minimizing dilution. Unlike blast hole sampling, which offers composite grade data post-blasting, drilling delivers detailed in situ grade estimates essential for real-time decision making in mine planning.

Pre-collar Drilling

Pre-collar drilling enhances blast hole sampling accuracy by enlarging the upper section of the hole, which stabilizes borehole walls and facilitates consistent core recovery in challenging geology. This method reduces contamination and sample mixing risks, allowing for more reliable assay data critical for resource estimation in mining operations.

Wet vs Dry Sample Collection

Wet sample collection in drilling captures slurry and water-laden material, providing a more representative geochemical analysis, whereas dry sample collection in blast hole sampling ensures minimal contamination and better preservation of particle integrity for accurate assay results. Selecting between wet and dry sampling impacts data quality, with wet methods favored for finer mineral dispersion and dry methods preferred for coarse, free-draining rock fragments.

Cone Splitter Sampling

Cone splitter sampling provides higher precision by consistently dividing drill core or rubble into representative sub-samples, minimizing particle size bias compared to traditional blast hole sampling techniques. This method improves data accuracy in mineral grade estimation, supporting better resource modeling and mine planning decisions.

Blast Movement Monitoring (BMM)

Blast Movement Monitoring (BMM) plays a critical role in optimizing blast hole sampling accuracy by precisely tracking the displacement and fragmentation of rock during blasting. This monitoring enables more reliable data collection and enhances the efficiency of mineral extraction compared to traditional drilling sampling methods.

Hyperspectral Core Scanning

Hyperspectral core scanning enhances drilling and blast hole sampling by providing rapid, non-destructive mineralogical analysis that improves ore body characterization and grade control. This advanced imaging technology captures detailed spectral information across core samples, enabling precise identification of mineral phases and reducing reliance on traditional, time-consuming chemical assays.

On-Blast Hole XRF Analysis

On-blast hole XRF analysis provides rapid, in-situ elemental data during drilling, enabling precise grade control and reducing the need for extensive lab-based assays. This technique enhances decision-making efficiency by delivering real-time compositional insights directly from blast holes, optimizing mining operations and minimizing material dilution.

Digital Blast Pattern Optimization

Digital Blast Pattern Optimization enhances drilling precision by integrating real-time data analytics and GPS mapping, significantly improving blast hole sampling accuracy and reducing operational costs. Advanced software algorithms analyze subsurface geology to tailor blast patterns, maximizing material fragmentation while minimizing environmental impact in mining operations.

Drilling vs Blast hole sampling Infographic

industrydif.com

industrydif.com