Flotation and sensor-based ore sorting are two critical methods used in mineral processing to enhance ore grade and recovery. Flotation relies on differences in the surface chemistry of minerals, effectively separating valuable minerals from gangue through the use of reagents and air bubbles, making it ideal for fine and complex ores. Sensor-based ore sorting leverages advanced technologies such as X-ray, infrared, or optical sensors to identify and separate ore particles based on physical or chemical properties, offering high precision and reduced waste in coarse ore processing.

Table of Comparison

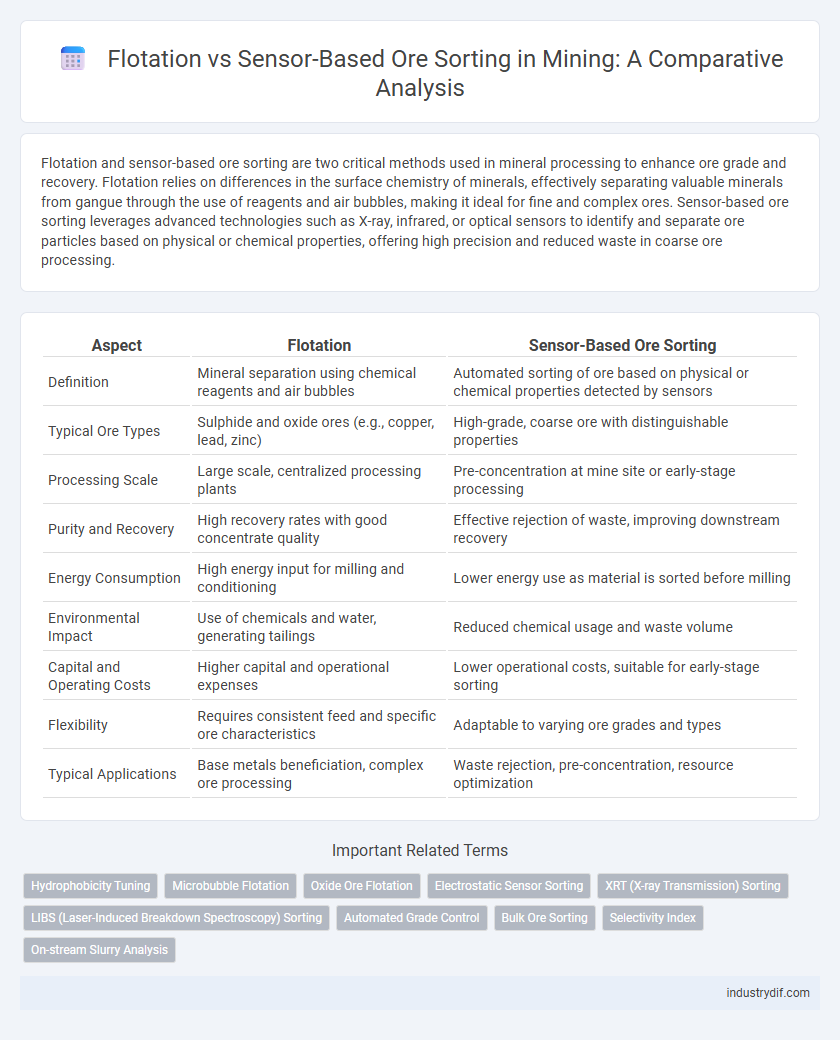

| Aspect | Flotation | Sensor-Based Ore Sorting |

|---|---|---|

| Definition | Mineral separation using chemical reagents and air bubbles | Automated sorting of ore based on physical or chemical properties detected by sensors |

| Typical Ore Types | Sulphide and oxide ores (e.g., copper, lead, zinc) | High-grade, coarse ore with distinguishable properties |

| Processing Scale | Large scale, centralized processing plants | Pre-concentration at mine site or early-stage processing |

| Purity and Recovery | High recovery rates with good concentrate quality | Effective rejection of waste, improving downstream recovery |

| Energy Consumption | High energy input for milling and conditioning | Lower energy use as material is sorted before milling |

| Environmental Impact | Use of chemicals and water, generating tailings | Reduced chemical usage and waste volume |

| Capital and Operating Costs | Higher capital and operational expenses | Lower operational costs, suitable for early-stage sorting |

| Flexibility | Requires consistent feed and specific ore characteristics | Adaptable to varying ore grades and types |

| Typical Applications | Base metals beneficiation, complex ore processing | Waste rejection, pre-concentration, resource optimization |

Introduction to Ore Processing Techniques in Mining

Flotation and sensor-based ore sorting are critical ore processing techniques used to enhance mineral recovery in mining operations. Flotation separates valuable minerals from gangue by exploiting differences in surface chemistry, optimizing concentrate grade and recovery rates. Sensor-based ore sorting utilizes advanced detection technologies, such as X-ray transmission or near-infrared spectroscopy, to identify and segregate ore particles, improving feed quality and reducing processing costs.

Overview of Flotation in Mineral Separation

Flotation is a widely used mineral separation process that exploits differences in surface properties of particles to selectively attach valuable minerals to air bubbles for recovery. This method efficiently separates sulfide ores and enhances concentrate grade while rejecting gangue minerals, making it essential in base metal mining. Flotation's adaptability to various ore types and its ability to achieve fine particle recovery provide a competitive advantage over sensor-based ore sorting technologies.

Principles and Mechanisms of Sensor-Based Ore Sorting

Sensor-based ore sorting utilizes advanced detection technologies such as X-ray transmission, near-infrared spectroscopy, and laser-induced breakdown spectroscopy to identify valuable minerals based on physical and chemical properties. The process involves real-time scanning of ore fragments on conveyor belts, where sensors detect variations in density, moisture, and elemental composition to classify and separate ore from waste material efficiently. This selective mechanism enhances ore concentration before grinding, reducing energy consumption and operational costs compared to traditional flotation methods that rely on chemical reagents and flotation cells for mineral separation.

Comparative Efficiency: Flotation vs. Sensor-Based Sorting

Flotation offers high recovery rates for fine particles by leveraging differences in mineral surface chemistry, making it efficient for complex ores with multiple valuable minerals. Sensor-based ore sorting provides rapid, real-time separation with reduced water usage and energy consumption, particularly effective in upgrading coarse particles before downstream processing. Both methods complement each other, as flotation excels in recovering fine minerals, while sensor-based sorting optimizes feed quality and reduces processing volumes.

Material Suitability: Selecting Appropriate Technology

Flotation excels in processing fine-grained ores with complex mineralogy, particularly sulfide and oxide minerals, delivering high recovery rates through chemical reagent use. Sensor-based ore sorting is highly effective for coarse, liberated ores where physical properties like color, density, or X-ray fluorescence can differentiate valuable minerals from waste. The choice between flotation and sensor-based sorting hinges on ore texture, liberation size, and mineral composition to optimize recovery and operational efficiency.

Environmental Impact and Sustainability Considerations

Flotation and sensor-based ore sorting differ significantly in environmental impact and sustainability, with sensor-based sorting offering more efficient waste reduction by selectively processing high-grade ore, resulting in lower energy consumption and reduced chemical use. Flotation often requires substantial water usage and introduces chemicals that can lead to tailings management challenges and potential contamination. Prioritizing sensor-based sorting enhances resource efficiency and mitigates environmental risks, supporting sustainable mining practices through improved ore recovery and minimal ecological footprint.

Economic Analysis and Cost-Efficiency

Flotation offers high recovery rates for fine particles but involves significant operational costs due to reagent consumption and energy-intensive processes. Sensor-based ore sorting reduces processing volumes by pre-concentrating ore, leading to lower energy use and decreased transportation and milling expenses. Economic analysis shows that sensor-based sorting can improve overall cost-efficiency by minimizing waste throughput and optimizing downstream flotation performance.

Technological Innovations in Flotation and Sensor Sorting

Technological innovations in flotation now incorporate advanced reagents and improved cell designs, enhancing mineral recovery and selectivity in complex ores. Sensor-based ore sorting utilizes hyperspectral imaging and X-ray transmission sensors to precisely identify and separate valuable minerals, reducing processing costs and enhancing overall efficiency. Integration of machine learning algorithms in sensor sorting systems further optimizes ore quality prediction and real-time decision-making.

Case Studies: Industry Applications and Outcomes

Case studies in mining highlight flotation's effectiveness in processing sulfide ores, achieving recovery rates above 90% in copper and lead-zinc operations. Sensor-based ore sorting demonstrates high precision in separating ore from waste rock, improving feed grades by up to 30% and reducing processing costs in gold and diamond mining. Combining flotation with sensor-based sorting in polymetallic mines optimizes resource recovery and enhances operational efficiency.

Future Trends in Ore Sorting and Processing Technologies

Future trends in ore sorting and processing technologies emphasize integrating flotation with advanced sensor-based sorting systems to enhance ore grade optimization and reduce energy consumption. Innovations in machine learning algorithms and hyperspectral imaging are driving higher precision in mineral identification, enabling more efficient separation of valuable minerals from waste. This synergy is expected to improve processing throughput, lower environmental impact, and optimize resource recovery in mining operations.

Related Important Terms

Hydrophobicity Tuning

Hydrophobicity tuning enhances flotation efficiency by selectively increasing the water-repellent properties of target minerals, enabling their separation from gangue material through air bubbles. Sensor-based ore sorting complements this by using advanced detectors to identify and segregate particles based on surface properties, but flotation's chemical adjustment of hydrophobicity offers finer control for ore beneficiation.

Microbubble Flotation

Microbubble flotation enhances ore recovery by using fine bubbles to selectively attach to valuable minerals, improving separation efficiency over traditional flotation methods. Compared to sensor-based ore sorting, microbubble flotation offers finer particle liberation and higher-grade concentrate, optimizing mineral extraction in complex ore bodies.

Oxide Ore Flotation

Oxide ore flotation maximizes recovery by exploiting differences in surface chemistry, enabling selective attachment of valuable minerals to air bubbles, which is especially effective for fine particles. Sensor-based ore sorting uses electromagnetic or X-ray sensors to identify and separate ore based on physical and chemical properties, offering rapid pre-concentration but often less effective recovery for complex oxide ores compared to flotation.

Electrostatic Sensor Sorting

Electrostatic sensor sorting in mining distinguishes valuable minerals by exploiting differences in electrical conductivity and charge, enabling precise separation of ore particles with high purity and recovery rates. Compared to flotation, electrostatic sensor sorting reduces water usage and operational costs, while providing efficient pre-concentration that enhances downstream processing performance.

XRT (X-ray Transmission) Sorting

XRT (X-ray Transmission) sorting leverages density differences to separate minerals with high precision, enhancing recovery rates and reducing operating costs compared to traditional flotation methods. Unlike flotation, which relies on chemical reagents and water, XRT sorting offers a dry, sensor-based solution that improves ore grade and minimizes environmental impact in mineral processing.

LIBS (Laser-Induced Breakdown Spectroscopy) Sorting

Sensor-based ore sorting using LIBS (Laser-Induced Breakdown Spectroscopy) offers precise elemental analysis by detecting the atomic emission spectra of materials, enabling real-time separation of valuable minerals from waste with minimal dilution. Compared to traditional flotation, LIBS sorting reduces water consumption and chemical use, increases recovery rates, and enhances the overall efficiency of the mineral processing stream.

Automated Grade Control

Automated grade control enhances ore processing efficiency by integrating flotation and sensor-based ore sorting, enabling real-time optimization of mineral recovery and feed quality. Sensor-based ore sorting detects and separates ore particles based on physical and chemical properties, while flotation refines concentrate purity, together reducing operational costs and maximizing yield.

Bulk Ore Sorting

Bulk ore sorting enhances mining efficiency by pre-concentrating valuable minerals through sensor-based detection of ore characteristics, enabling the rejection of waste rock before processing. Flotation, a downstream mineral separation technique, relies on chemical and physical differences to separate ore particles, making bulk ore sorting an effective complement by reducing feed variability and increasing overall plant recovery.

Selectivity Index

Flotation achieves a higher Selectivity Index by exploiting mineral surface chemistry to separate valuable ore from gangue with precision, while sensor-based ore sorting relies on physical property contrasts such as color or density but typically exhibits lower selectivity. The superior Selectivity Index of flotation enhances concentrate grade and recovery rates, making it more effective for complex sulfide ores compared to sensor-based sorting.

On-stream Slurry Analysis

On-stream slurry analysis enhances flotation efficiency by continuously monitoring particle size and mineral composition, enabling real-time process adjustments that maximize recovery rates. Sensor-based ore sorting relies on detecting physical and chemical properties before processing, reducing dilution and increasing grade but lacks the dynamic feedback provided by slurry analysis for optimizing flotation performance.

Flotation vs Sensor-based ore sorting Infographic

industrydif.com

industrydif.com