Heap leaching involves stacking ore in large heaps and applying chemical solutions to extract metals, offering cost-effective recovery for low-grade ores. Microbial leaching employs bacteria to biologically oxidize minerals, enhancing metal extraction efficiency in complex ores. Both techniques improve metal recovery but differ in environmental impact, processing time, and operational complexity.

Table of Comparison

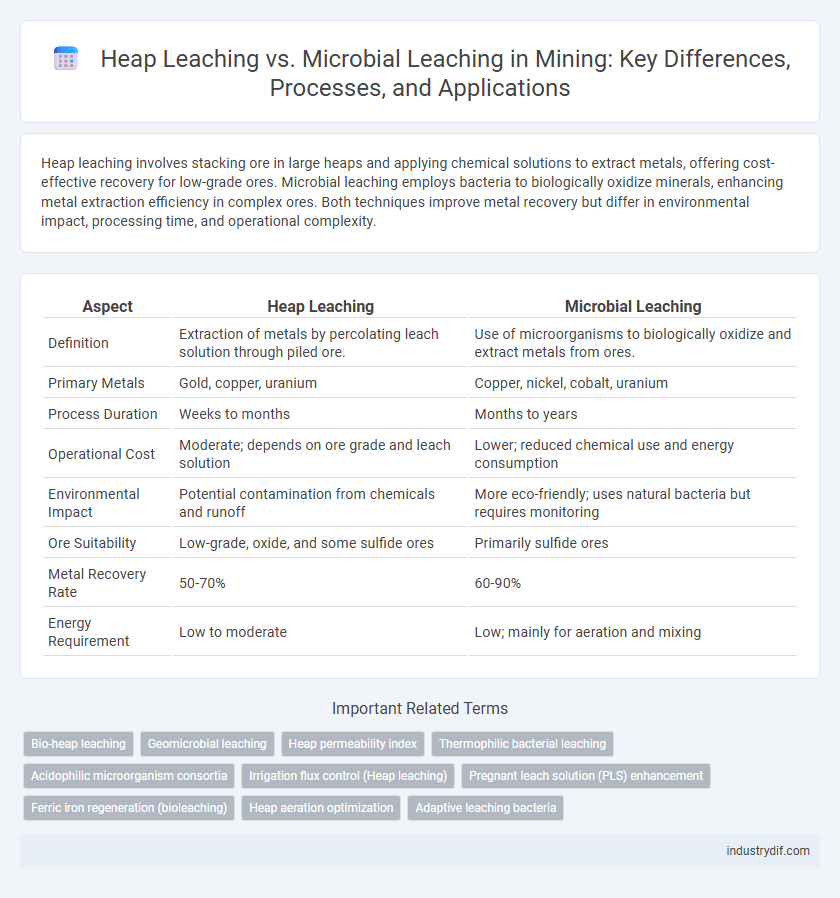

| Aspect | Heap Leaching | Microbial Leaching |

|---|---|---|

| Definition | Extraction of metals by percolating leach solution through piled ore. | Use of microorganisms to biologically oxidize and extract metals from ores. |

| Primary Metals | Gold, copper, uranium | Copper, nickel, cobalt, uranium |

| Process Duration | Weeks to months | Months to years |

| Operational Cost | Moderate; depends on ore grade and leach solution | Lower; reduced chemical use and energy consumption |

| Environmental Impact | Potential contamination from chemicals and runoff | More eco-friendly; uses natural bacteria but requires monitoring |

| Ore Suitability | Low-grade, oxide, and some sulfide ores | Primarily sulfide ores |

| Metal Recovery Rate | 50-70% | 60-90% |

| Energy Requirement | Low to moderate | Low; mainly for aeration and mixing |

Introduction to Heap Leaching and Microbial Leaching

Heap leaching involves stacking crushed ore in large piles and applying chemical solutions to extract valuable metals such as gold, copper, or uranium through percolation. Microbial leaching uses specific bacteria to oxidize and dissolve metal sulfides, enhancing metal recovery from low-grade ores or complex mineral matrices. Both methods offer cost-effective and environmentally friendly alternatives to traditional mining techniques, optimizing metal extraction efficiency.

Fundamental Principles of Heap Leaching

Heap leaching involves stacking crushed ore into large heaps and applying a leaching solvent, typically a weak acid or cyanide solution, to percolate through the material and dissolve valuable metals such as gold or copper. The process relies on gravity and chemical reactions where the solvent reacts with the metal-bearing minerals, allowing metals to be recovered from the pregnant leach solution collected at the base. Fundamental principles emphasize ore permeability, leach solution chemistry, and heap design to optimize metal recovery and minimize environmental impact.

Overview of Microbial Leaching Processes

Microbial leaching utilizes specific bacteria such as Acidithiobacillus ferrooxidans to oxidize sulfide minerals, enabling the extraction of metals like copper and gold from low-grade ores. This biohydrometallurgical process thrives under controlled conditions that optimize microbial activity, including pH, temperature, and aeration levels. Compared to heap leaching, microbial leaching offers enhanced metal recovery rates and environmentally friendly protocols by minimizing the use of hazardous chemicals.

Key Differences Between Heap Leaching and Bioleaching

Heap leaching involves stacking crushed ore on a lined pad and irrigating it with chemical solutions to extract metals, primarily copper and gold, whereas microbial leaching (bioleaching) uses bacteria to catalyze the breakdown of minerals, enhancing metal recovery from low-grade ores. Heap leaching is generally simpler and more cost-effective but slower, while bioleaching offers higher extraction efficiency for sulfide ores by biologically oxidizing metal sulfides. Environmental impact differs as heap leaching may risk chemical runoff, but bioleaching is considered more eco-friendly due to its reliance on natural biological processes.

Ore Types Suitable for Each Leaching Method

Heap leaching is highly effective for oxide ores and low-grade sulfide ores such as copper oxide and gold-bearing ores, benefiting from the extensive permeability and leachability of these materials. Microbial leaching excels in processing refractory sulfide ores, including chalcopyrite and pentlandite, where bacteria like Acidithiobacillus ferrooxidans enhance metal recovery by bio-oxidizing sulfide minerals. Selecting between heap leaching and microbial leaching largely depends on ore mineralogy, with heap leaching favored for oxide and oxidized sulfide ores and microbial leaching preferred for complex sulfide ores requiring biooxidation.

Environmental Impact: Heap vs. Microbial Leaching

Heap leaching often results in substantial environmental risks due to the use of strong chemical reagents, such as cyanide, which can contaminate soil and water sources if not properly managed. Microbial leaching, employing naturally occurring bacteria to extract metals, offers a more eco-friendly alternative by reducing toxic chemical use and minimizing hazardous waste production. The lower energy consumption and biodegradable by-products of microbial leaching markedly lessen its environmental footprint compared to conventional heap leaching methods.

Economic Considerations and Cost Efficiency

Heap leaching offers lower initial capital costs and simpler operational requirements, making it economically viable for low-grade ore deposits. Microbial leaching, while potentially slower, enhances metal recovery rates and reduces chemical reagent expenses, improving long-term cost efficiency. The choice depends on ore characteristics and scale, with microbial leaching favored for sustainable, cost-effective extraction in complex mineral matrices.

Operational Challenges and Limitations

Heap leaching faces operational challenges such as low metal recovery rates and the need for large land areas, while microbial leaching is limited by slow reaction kinetics and sensitivity to environmental conditions like pH and temperature. Heap leaching requires careful management of acid consumption and leachate containment to prevent environmental contamination. Microbial leaching demands precise control of microbial populations and nutrient supply to optimize biooxidation processes.

Technological Advances in Leaching Processes

Heap leaching has seen technological advances through improved heap design, enhanced irrigation systems, and real-time monitoring using sensors, increasing metal recovery rates and operational efficiency. Microbial leaching benefits from bioengineering innovations that optimize bacterial strains and enhance biofilm formation, accelerating metal solubilization in low-grade ores. Both methods integrate automation and data analytics to optimize leaching kinetics, minimize environmental impact, and reduce processing costs in modern mining operations.

Future Trends in Metal Extraction Technologies

Heap leaching involves the percolation of chemical solutions through piled ore to extract metals, while microbial leaching uses bacteria to biologically break down ores, enhancing metal recovery. Future trends prioritize integrating microbial leaching with heap leaching to improve extraction efficiency and reduce environmental impact, leveraging advances in biotechnology and bioengineering. Emerging technologies focus on optimizing microbial consortia and genetic modification to target refractory ores, supporting sustainable and cost-effective metal extraction.

Related Important Terms

Bio-heap leaching

Bio-heap leaching integrates microbial leaching within traditional heap leaching to enhance metal recovery by utilizing bacteria like Acidithiobacillus ferrooxidans to oxidize sulfide minerals, increasing metal solubilization efficiency. This method reduces environmental impact and operational costs compared to conventional chemical leaching, making it a sustainable choice for extracting copper, gold, and uranium from low-grade ores.

Geomicrobial leaching

Geomicrobial leaching uses specific bacteria and archaea to accelerate the oxidation of sulfide minerals, enhancing metal recovery rates in low-grade ores compared to traditional heap leaching. This eco-friendly process reduces the need for harsh chemicals while improving copper, gold, and uranium extraction efficiency in large-scale mining operations.

Heap permeability index

Heap permeability index is critical in heap leaching as it determines the flow rate of leachate through the ore, directly impacting metal recovery efficiency. In microbial leaching, enhanced permeability is achieved by biochemical reactions that break down mineral matrices, often resulting in higher permeability indices compared to conventional heap leaching methods.

Thermophilic bacterial leaching

Thermophilic bacterial leaching, a specialized form of microbial leaching, employs heat-loving bacteria such as Sulfolobus metallicus to efficiently extract metals from ores at elevated temperatures, enhancing metal recovery rates compared to conventional heap leaching. This biooxidation process accelerates the breakdown of sulfide minerals, making it particularly effective for refractory gold and copper ores where traditional heap leaching with cyanide shows limitations.

Acidophilic microorganism consortia

Heap leaching utilizes acidophilic microorganism consortia, such as Acidithiobacillus ferrooxidans and Leptospirillum spp., to bio-oxidize sulfide minerals, enhancing metal recovery in low-grade ores through large-scale, economically viable processes. Microbial leaching employs similar acidophilic bacteria but is often optimized in controlled bioreactors, allowing for intensified metal solubilization via tailored microbial community management and environmental conditions.

Irrigation flux control (Heap leaching)

Heap leaching requires precise irrigation flux control to optimize percolation rates and maximize metal recovery while minimizing reagent loss and environmental impact. Effective management of irrigation flux enhances heap permeability and ensures uniform distribution of the leaching solution, crucial for maintaining microbial activity and heap stability.

Pregnant leach solution (PLS) enhancement

Heap leaching relies on chemical reagents to extract metals into the pregnant leach solution (PLS), while microbial leaching employs bacteria to bio-oxidize minerals, enhancing metal recovery rates and improving PLS quality. Microbial leaching increases the concentration of valuable metals in the PLS by accelerating the breakdown of sulfide ores, leading to more efficient metal recovery compared to conventional heap leaching.

Ferric iron regeneration (bioleaching)

Heap leaching utilizes chemical agents to dissolve metals from ores, whereas microbial leaching employs bacteria to oxidize ferrous iron to ferric iron, enhancing the regeneration of ferric ions crucial for sustained metal solubilization. Ferric iron regeneration in bioleaching accelerates the oxidative dissolution of sulfide minerals, improving metal recovery rates in mining operations.

Heap aeration optimization

Heap aeration optimization enhances oxygen diffusion rates crucial for microbial leaching, improving biooxidation efficiency and metal recovery in low-grade ores. Traditional heap leaching relies on chemical reagents, while optimized microbial heap leaching leverages aerobic microorganisms, reducing environmental impact and operational costs.

Adaptive leaching bacteria

Adaptive leaching bacteria enhance heap leaching efficiency by optimizing metal recovery under varying environmental conditions, outperforming traditional microbial leaching methods. These resilient microorganisms adjust to fluctuations in pH, temperature, and mineral composition, accelerating the bio-oxidation process essential for extracting copper and gold from low-grade ores.

Heap leaching vs Microbial leaching Infographic

industrydif.com

industrydif.com