Hydraulic mining involves using high-pressure water jets to dislodge rock material or move sediment, which can lead to significant environmental disruption and sedimentation issues. Geopolymer backfill, on the other hand, employs sustainable, cement-like materials created from industrial by-products to fill voids in mined-out areas, enhancing ground stability and reducing waste. Choosing geopolymer backfill over hydraulic mining techniques contributes to safer mine operations and more environmentally friendly reclamation practices.

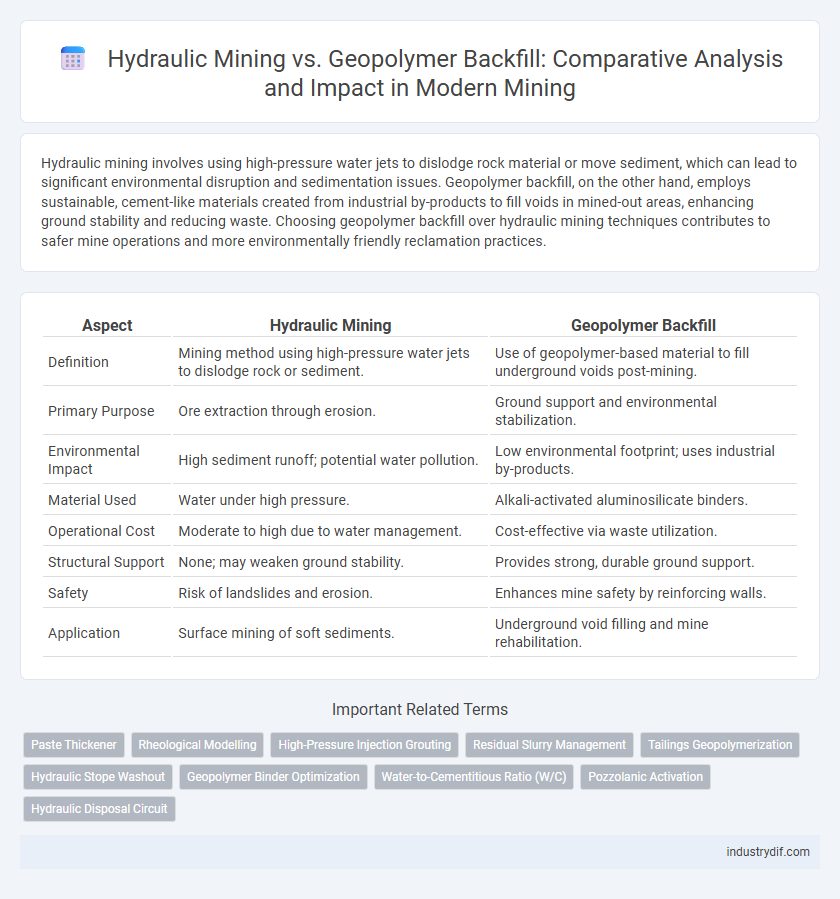

Table of Comparison

| Aspect | Hydraulic Mining | Geopolymer Backfill |

|---|---|---|

| Definition | Mining method using high-pressure water jets to dislodge rock or sediment. | Use of geopolymer-based material to fill underground voids post-mining. |

| Primary Purpose | Ore extraction through erosion. | Ground support and environmental stabilization. |

| Environmental Impact | High sediment runoff; potential water pollution. | Low environmental footprint; uses industrial by-products. |

| Material Used | Water under high pressure. | Alkali-activated aluminosilicate binders. |

| Operational Cost | Moderate to high due to water management. | Cost-effective via waste utilization. |

| Structural Support | None; may weaken ground stability. | Provides strong, durable ground support. |

| Safety | Risk of landslides and erosion. | Enhances mine safety by reinforcing walls. |

| Application | Surface mining of soft sediments. | Underground void filling and mine rehabilitation. |

Introduction to Hydraulic Mining and Geopolymer Backfill

Hydraulic mining uses high-pressure water jets to dislodge rock material or move sediment, enabling efficient extraction of minerals from alluvial deposits. Geopolymer backfill involves using synthetic inorganic polymers to stabilize underground voids, enhancing mine safety and reducing environmental impact. Combining effective hydraulic mining with geopolymer backfill technology supports sustainable mineral extraction and site rehabilitation.

Historical Evolution of Mining Backfill Techniques

Hydraulic mining emerged in the 19th century as a dominant technique, utilizing high-pressure water jets to dislodge rock and soil for gold extraction, revolutionizing placer mining operations. In contrast, geopolymer backfill represents a modern innovation, leveraging alkali-activated materials to create sustainable, low-permeability backfill that enhances underground mine stability. The transition from hydraulic methods to geopolymer backfill reflects significant advancements in environmental impact reduction, material science, and mine safety protocols over time.

Core Principles of Hydraulic Mining

Hydraulic mining operates by using high-pressure water jets to dislodge rock and sediment, enabling the extraction of valuable minerals from alluvial deposits. This method relies on gravity separation to transport loosened materials through sluices, optimizing mineral recovery while minimizing manual labor. Core principles emphasize efficient water pressure control and sediment flow management to maximize ore extraction and reduce environmental impact.

Geopolymer Backfill: Composition and Advantages

Geopolymer backfill consists of aluminosilicate materials activated by alkaline solutions, creating a chemically bonded matrix with high compressive strength and durability. This sustainable alternative to hydraulic mining waste reduces environmental impact by utilizing industrial by-products such as fly ash and slag, enhancing the structural integrity of mine voids. Its advantages include improved ground stability, reduced water usage, and lower greenhouse gas emissions compared to conventional hydraulic mining techniques.

Comparative Analysis: Efficiency and Productivity

Hydraulic mining offers rapid material displacement through high-pressure water jets, enabling large-scale ore extraction but often resulting in environmental degradation and resource wastage. Geopolymer backfill improves productivity by stabilizing mine voids with eco-friendly materials, reducing ground subsidence and enhancing worker safety while promoting sustainable mining practices. Efficiency metrics reveal that geopolymer backfill optimizes resource utilization and lowers operational downtime compared to hydraulic mining's higher energy consumption and sediment management challenges.

Environmental Impact Assessment of Both Methods

Hydraulic mining causes significant environmental degradation through soil erosion, sedimentation of waterways, and loss of biodiversity, raising concerns about water quality and aquatic ecosystems. Geopolymer backfill presents a sustainable alternative by utilizing industrial waste materials to stabilize mine voids, reducing the carbon footprint and minimizing groundwater contamination risks. Environmental Impact Assessments reveal that geopolymer backfill significantly lowers pollutant discharge compared to traditional hydraulic mining, supporting improved ecological preservation.

Cost-Benefit Overview: Hydraulic vs Geopolymer Solutions

Hydraulic mining incurs high operational costs due to water usage, sediment management, and environmental mitigation measures, while geopolymer backfill offers a cost-efficient alternative with reduced waste and improved ground stability. Geopolymer solutions lower long-term expenses by minimizing environmental remediation and enhancing structural integrity of mine voids, directly impacting overall project economics. Selecting geopolymer backfill optimizes resource utilization and capital expenditure compared to the fluctuating costs of hydraulic systems driven by water and energy demand.

Safety Considerations and Worker Health

Hydraulic mining poses significant risks to worker safety due to high-pressure water jets and unstable debris flows, increasing the likelihood of accidents and respiratory issues from dust exposure. Geopolymer backfill provides a safer alternative by stabilizing underground voids, reducing collapse hazards, and limiting airborne contaminants. This method enhances worker health by minimizing exposure to hazardous materials and improving overall mine structural integrity.

Technology Integration and Future Trends

Hydraulic mining leverages high-pressure water jets to dislodge rock material, enabling efficient extraction but often resulting in significant environmental disruption, whereas geopolymer backfill technology involves the use of synthetic binders made from industrial by-products to stabilize mine voids and reduce ecological impact. Integrating real-time monitoring systems and automation in hydraulic mining is driving improvements in operational safety and precision, while advancements in geopolymer composites emphasize enhanced durability and reduced carbon footprints. Future trends indicate a shift towards hybrid solutions combining hydraulic extraction with geopolymer stabilization to optimize resource recovery and promote sustainable mining practices.

Conclusion: Choosing the Optimal Mining Backfill Method

Hydraulic mining offers rapid excavation and efficient material removal but poses significant environmental challenges, including sedimentation and water pollution. Geopolymer backfill provides enhanced structural stability and sustainable waste utilization by incorporating industrial byproducts, reducing the ecological footprint. Selecting the optimal backfill method depends on balancing operational efficiency, environmental impact, and long-term mine stability tailored to site-specific conditions.

Related Important Terms

Paste Thickener

Hydraulic mining involves the use of high-pressure water jets to dislodge rock material, whereas geopolymer backfill utilizes industrial by-products mixed with chemical activators to create a solid, sustainable paste. Paste thickeners optimize the consistency and density of the backfill slurry, improving its stability and reducing water consumption in underground mining operations.

Rheological Modelling

Hydraulic mining relies on fluid mechanics principles to optimize slurry flow, making rheological modeling essential for predicting sediment transport and erosion characteristics. In contrast, geopolymer backfill requires precise rheological models to ensure proper viscosity and yield stress for effective pipeline transport and stable deposition in underground voids.

High-Pressure Injection Grouting

High-pressure injection grouting in hydraulic mining effectively stabilizes loose sediments by injecting fluid materials under pressure, while geopolymer backfill offers superior chemical resistance and structural strength for mine void consolidation. The choice between high-pressure injection grouting and geopolymer backfill depends on factors such as soil permeability, environmental impact, and long-term mechanical performance in underground mining operations.

Residual Slurry Management

Hydraulic mining generates large volumes of residual slurry containing fine particles and chemical contaminants, demanding effective management to prevent environmental pollution. Geopolymer backfill utilizes industrial waste materials to solidify residual slurry in situ, reducing slurry disposal issues and enhancing ground stability in mining operations.

Tailings Geopolymerization

Tailings geopolymerization transforms mining waste into environmentally stable materials, significantly reducing the toxic runoff associated with hydraulic mining tailings. This method not only mitigates acid mine drainage but also improves the mechanical strength and durability of backfill used in subterranean mining operations.

Hydraulic Stope Washout

Hydraulic mining often causes hydraulic stope washout, leading to significant erosion and instability within underground stopes, whereas geopolymer backfill provides a chemically stable and environmentally friendly alternative that enhances stope support and reduces washout risks. The use of geopolymer backfill minimizes water infiltration and mitigates hydraulic pressure, improving ground control and extending mine life in hydro-affected stopes.

Geopolymer Binder Optimization

Geopolymer binder optimization in mining backfill enhances strength and durability by tailoring the aluminosilicate composition and curing conditions to reduce permeability and improve chemical resistance compared to hydraulic mining methods. Optimized geopolymer formulations enable efficient waste utilization and lower environmental impact through reduced water usage and minimized tailings disposal.

Water-to-Cementitious Ratio (W/C)

Hydraulic mining typically involves a higher water-to-cementitious ratio (W/C), ranging from 0.45 to 0.60, which enhances fluidity but can reduce strength and durability of backfill materials. In contrast, geopolymer backfill systems maintain a lower W/C ratio, often between 0.30 and 0.45, resulting in improved mechanical properties and reduced permeability crucial for sustainable mine ground support.

Pozzolanic Activation

Hydraulic mining generates large volumes of loose tailings requiring effective stabilization, where geopolymer backfill leverages pozzolanic activation by chemically reacting aluminosilicate materials with alkaline activators to produce durable, cementitious binders. This pozzolanic reaction in geopolymer backfill enhances mechanical strength and reduces environmental impact compared to conventional hydraulic tailings management.

Hydraulic Disposal Circuit

Hydraulic mining employs a hydraulic disposal circuit to transport slurry efficiently through pipelines, minimizing sediment buildup and reducing environmental impact by controlling tailings flow. Geopolymer backfill, while improving underground ground control and reducing waste volumes, does not replace the hydraulic disposal circuit's ability to handle large volumes of tailings in surface mining operations.

Hydraulic mining vs Geopolymer backfill Infographic

industrydif.com

industrydif.com