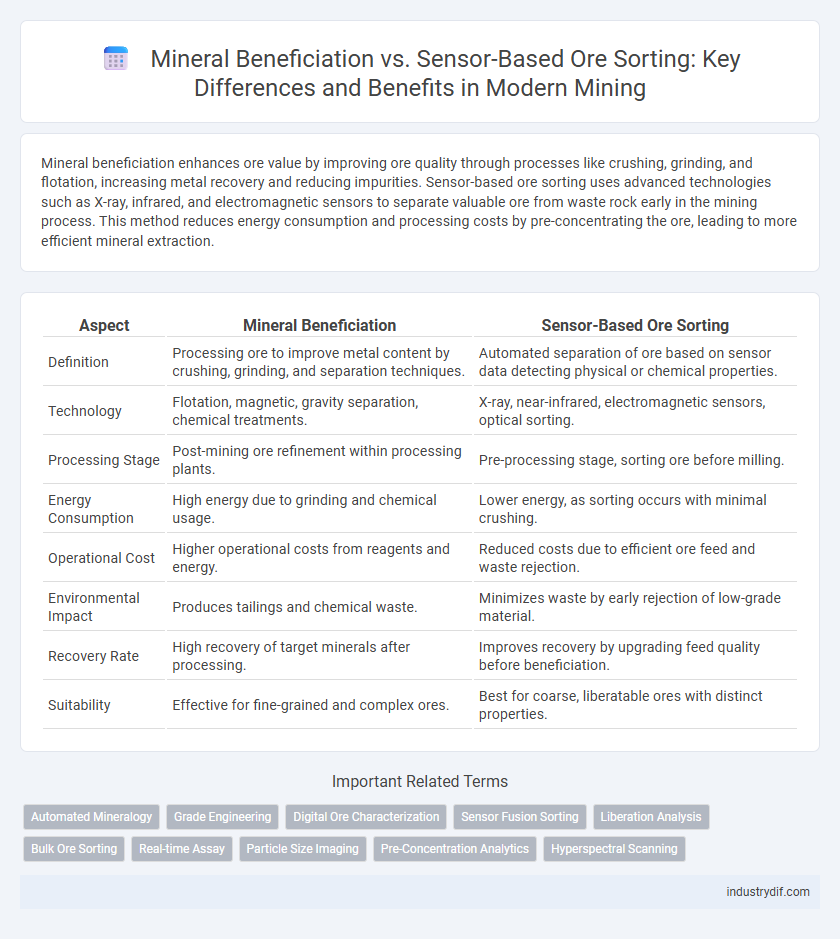

Mineral beneficiation enhances ore value by improving ore quality through processes like crushing, grinding, and flotation, increasing metal recovery and reducing impurities. Sensor-based ore sorting uses advanced technologies such as X-ray, infrared, and electromagnetic sensors to separate valuable ore from waste rock early in the mining process. This method reduces energy consumption and processing costs by pre-concentrating the ore, leading to more efficient mineral extraction.

Table of Comparison

| Aspect | Mineral Beneficiation | Sensor-Based Ore Sorting |

|---|---|---|

| Definition | Processing ore to improve metal content by crushing, grinding, and separation techniques. | Automated separation of ore based on sensor data detecting physical or chemical properties. |

| Technology | Flotation, magnetic, gravity separation, chemical treatments. | X-ray, near-infrared, electromagnetic sensors, optical sorting. |

| Processing Stage | Post-mining ore refinement within processing plants. | Pre-processing stage, sorting ore before milling. |

| Energy Consumption | High energy due to grinding and chemical usage. | Lower energy, as sorting occurs with minimal crushing. |

| Operational Cost | Higher operational costs from reagents and energy. | Reduced costs due to efficient ore feed and waste rejection. |

| Environmental Impact | Produces tailings and chemical waste. | Minimizes waste by early rejection of low-grade material. |

| Recovery Rate | High recovery of target minerals after processing. | Improves recovery by upgrading feed quality before beneficiation. |

| Suitability | Effective for fine-grained and complex ores. | Best for coarse, liberatable ores with distinct properties. |

Introduction to Mineral Beneficiation and Sensor-Based Ore Sorting

Mineral beneficiation improves ore quality by separating valuable minerals from gangue using techniques such as flotation, magnetic separation, and gravity concentration. Sensor-based ore sorting utilizes advanced sensors like X-ray transmission, near-infrared spectroscopy, and laser-induced breakdown spectroscopy to identify and segregate ore based on physical and chemical properties. Both methods enhance processing efficiency by reducing waste and improving feed grade to downstream mineral processing plants.

Principles and Mechanisms of Mineral Beneficiation

Mineral beneficiation employs physical and chemical processes such as crushing, grinding, flotation, and magnetic separation to enhance ore quality by removing impurities and increasing valuable mineral concentration. It relies on differences in mineral density, surface properties, and magnetic susceptibility to selectively separate valuable minerals from gangue. Sensor-based ore sorting uses real-time optical, X-ray, or electromagnetic sensors to analyze and segregate ore particles based on specific mineralogical characteristics, optimizing feed quality before beneficiation processes.

Fundamentals of Sensor-Based Ore Sorting Technologies

Sensor-based ore sorting technologies utilize advanced sensors such as X-ray transmission, near-infrared, and electromagnetic sensors to identify and separate valuable minerals from waste rock at an early stage, enhancing efficiency and reducing energy consumption. Unlike conventional mineral beneficiation, which relies heavily on grinding and flotation processes, sensor-based sorting operates on particle-level analysis, enabling selective removal of low-grade material before further processing. This fundamental shift in ore preparation optimizes downstream processing, decreases operational costs, and improves overall resource recovery in mining operations.

Comparative Analysis: Process Efficiency

Mineral beneficiation enhances ore quality by crushing, grinding, and flotation, achieving up to 90% recovery rates for targeted minerals, whereas sensor-based ore sorting uses X-ray, laser, or optical sensors to pre-concentrate ore with up to 85% efficiency, reducing load on downstream processes. Beneficiation requires higher energy and water consumption, while sensor-based sorting offers a more sustainable approach by minimizing waste and lowering operational costs. Both techniques improve process efficiency but differ in scale and environmental impact, with sensor-based sorting increasingly preferred for low-grade ores and early-stage ore processing.

Economic Considerations in Ore Processing

Mineral beneficiation enhances ore value by improving grade and recovery through processes like crushing, grinding, and flotation, though it often involves high capital and operational costs. Sensor-based ore sorting reduces processing volume by selectively rejecting waste rock early, lowering energy consumption and increasing throughput, resulting in significant cost savings. Economic evaluations favor sensor-based sorting when dealing with low-grade ores or complex deposits where reducing downstream processing expenses is crucial.

Environmental Impact: Traditional Beneficiation vs. Sensor Sorting

Mineral beneficiation often consumes large volumes of water and energy, generating significant tailings and environmental contaminants, which strain local ecosystems. Sensor-based ore sorting reduces waste by pre-concentrating ore, lowering processing volumes and associated emissions while minimizing water usage. This technology offers a cleaner, more sustainable alternative by improving resource efficiency and reducing the ecological footprint of mining operations.

Technological Advancements in Ore Sorting Solutions

Technological advancements in mineral beneficiation have significantly enhanced sensor-based ore sorting, using hyperspectral imaging, X-ray transmission, and laser-induced breakdown spectroscopy to improve mineral discrimination and concentrate quality. Modern sensor-based ore sorting systems enable precise separation of valuable minerals from waste rock at early processing stages, reducing energy consumption and increasing throughput efficiency. Integration of machine learning algorithms further refines sorting accuracy, maximizing recovery rates and minimizing operational costs in beneficiation plants.

Integration of Sensor-Based Sorting in Existing Beneficiation Plants

Integrating sensor-based ore sorting into existing mineral beneficiation plants enhances processing efficiency by pre-concentrating ore, reducing waste, and lowering energy consumption. Sensor-based sorting technologies, such as X-ray transmission and near-infrared sensors, enable selective ore feeding, improving downstream flotation and gravity separation performance. This integration optimizes plant throughput, decreases operational costs, and increases recovery rates for valuable minerals.

Case Studies: Industrial Applications and Success Stories

Industrial applications of mineral beneficiation and sensor-based ore sorting reveal significant improvements in ore grade and recovery rates, as demonstrated in mining operations at the Olympic Dam and Kiruna mines. Case studies highlight how sensor-based ore sorting technology enhances feed quality and reduces processing costs by removing waste material early in the production chain. Success stories emphasize the integration of both methods to optimize resource efficiency and minimize environmental impact in large-scale copper and iron ore extraction projects.

Future Trends in Ore Processing and Value Recovery

Mineral beneficiation and sensor-based ore sorting represent pivotal advancements in ore processing, with sensor-based sorting offering enhanced precision in separating valuable minerals from waste, thereby improving recovery rates and reducing energy consumption. Emerging trends emphasize integrating AI-driven sensor technologies to optimize sorting efficiency and lower operational costs, promoting sustainable mining practices. Future value recovery strategies increasingly rely on real-time data analytics and machine learning algorithms to refine mineral characterization and maximize extraction from low-grade ores.

Related Important Terms

Automated Mineralogy

Automated mineralogy enhances mineral beneficiation by providing precise, quantitative mineralogical data that improves ore characterization and process optimization, while sensor-based ore sorting selectively segregates ore based on real-time sensor inputs, increasing feed grade and reducing waste. Integrating automated mineralogical techniques with sensor-based sorting technologies boosts recovery rates and operational efficiency in mining workflows.

Grade Engineering

Mineral beneficiation enhances ore quality through physical and chemical processes like flotation and magnetic separation, improving mineral concentration and reducing impurities for efficient extraction. Sensor-based ore sorting utilizes real-time data from technologies such as X-ray transmission and near-infrared spectroscopy to selectively separate high-grade material from low-grade waste, optimizing grade engineering by increasing plant feed grade and reducing processing costs.

Digital Ore Characterization

Digital ore characterization enhances mineral beneficiation by providing precise data on ore variability, enabling tailored processing strategies that improve recovery rates and reduce waste. Sensor-based ore sorting complements this by using real-time spectral and X-ray analysis to segregate valuable minerals from waste, increasing overall plant efficiency and lowering operational costs.

Sensor Fusion Sorting

Sensor Fusion Sorting integrates data from multiple sensor technologies such as X-ray, near-infrared, and laser spectroscopy to enhance ore grade accuracy and improve mineral beneficiation efficiency. This method reduces waste by precisely segregating valuable minerals from gangue, thereby increasing the overall yield and lowering processing costs.

Liberation Analysis

Liberation analysis plays a critical role in both mineral beneficiation and sensor-based ore sorting by evaluating the degree to which valuable minerals are freed from gangue, enabling more efficient separation. While mineral beneficiation relies on liberation data to optimize grinding and flotation processes, sensor-based ore sorting uses real-time liberation metrics to rapidly classify and segregate ore fragments, enhancing overall resource recovery and reducing processing costs.

Bulk Ore Sorting

Bulk ore sorting enhances mineral beneficiation by pre-concentrating ore before processing, increasing recovery rates and reducing energy consumption. Sensor-based ore sorting technology uses advanced sensors like X-ray and near-infrared to distinguish valuable minerals from waste, optimizing overall mine efficiency.

Real-time Assay

Mineral beneficiation enhances ore quality through physical or chemical processes, achieving higher ore grades but often with slower throughput compared to sensor-based ore sorting that uses real-time assay data to rapidly identify and separate valuable minerals on conveyors. Real-time assay technology in sensor-based sorting enables immediate compositional analysis, optimizing ore feed to downstream processes and reducing waste with precise, data-driven decisions.

Particle Size Imaging

Particle size imaging enhances sensor-based ore sorting by accurately identifying and classifying minerals based on detailed size and shape analysis, improving sorting efficiency and reducing waste. Mineral beneficiation traditionally relies on physical and chemical separation methods, whereas sensor-based sorting combined with particle size imaging enables real-time, non-destructive mineral discrimination, optimizing processing flows.

Pre-Concentration Analytics

Mineral beneficiation enhances ore value by separating valuable minerals from waste through physical or chemical processes, while sensor-based ore sorting uses advanced sensors and machine learning algorithms to identify and separate ore particles before processing. Pre-concentration analytics in sensor-based sorting optimize ore feed quality, reduce energy consumption, and increase recovery rates by enabling real-time characterization of ore mineralogy and grade variability.

Hyperspectral Scanning

Hyperspectral scanning enhances mineral beneficiation by providing detailed spectral data that enables precise ore characterization and improved separation efficiency. Sensor-based ore sorting with hyperspectral technology reduces processing costs and increases recovery rates by accurately identifying mineral compositions in real-time.

Mineral beneficiation vs Sensor-based ore sorting Infographic

industrydif.com

industrydif.com