Open-pit mining involves excavating large surface areas to extract ore, resulting in significant landscape disruption and higher operational costs. In-situ leaching minimizes environmental impact by injecting solvents into the ore body to dissolve minerals, allowing extraction without extensive excavation. This method reduces surface disturbance and water consumption, making it a more sustainable choice for certain mineral deposits.

Table of Comparison

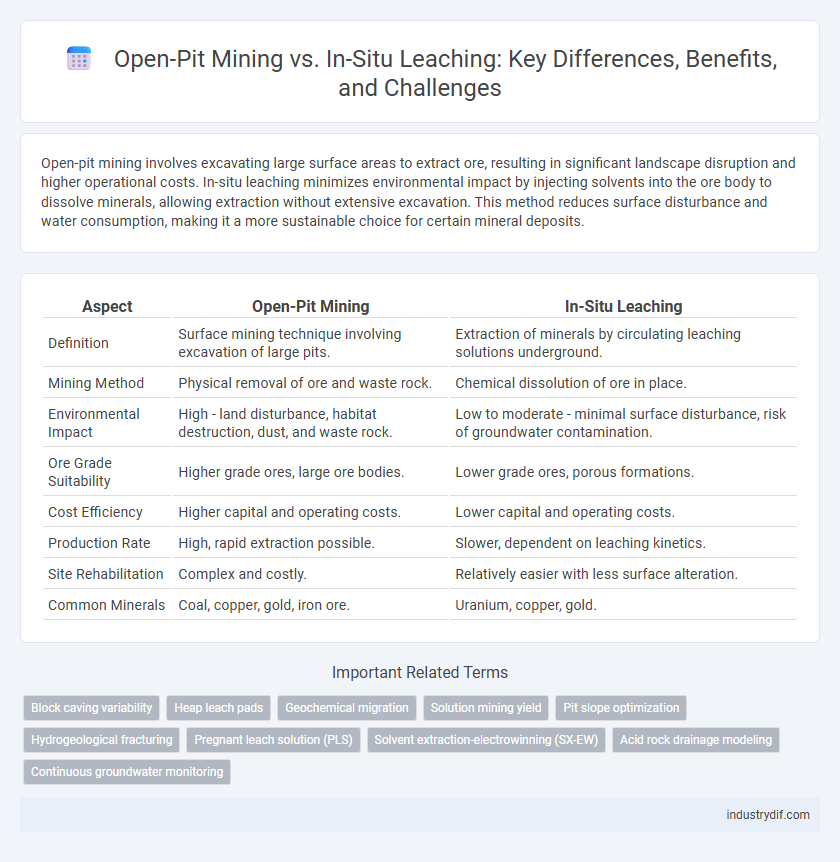

| Aspect | Open-Pit Mining | In-Situ Leaching |

|---|---|---|

| Definition | Surface mining technique involving excavation of large pits. | Extraction of minerals by circulating leaching solutions underground. |

| Mining Method | Physical removal of ore and waste rock. | Chemical dissolution of ore in place. |

| Environmental Impact | High - land disturbance, habitat destruction, dust, and waste rock. | Low to moderate - minimal surface disturbance, risk of groundwater contamination. |

| Ore Grade Suitability | Higher grade ores, large ore bodies. | Lower grade ores, porous formations. |

| Cost Efficiency | Higher capital and operating costs. | Lower capital and operating costs. |

| Production Rate | High, rapid extraction possible. | Slower, dependent on leaching kinetics. |

| Site Rehabilitation | Complex and costly. | Relatively easier with less surface alteration. |

| Common Minerals | Coal, copper, gold, iron ore. | Uranium, copper, gold. |

Overview of Open-Pit Mining and In-Situ Leaching

Open-pit mining involves excavating large open holes to extract ore near the surface, often used for minerals like copper and gold. In-situ leaching injects chemical solutions directly into the ore body to dissolve minerals underground, commonly applied to uranium and copper deposits. Open-pit mining offers high recovery rates and rapid extraction, while in-situ leaching minimizes surface disturbance and environmental impact.

Geological Suitability and Resource Assessment

Open-pit mining is geologically suitable for shallow, large, and relatively homogeneous ore deposits with stable rock formations, enabling efficient excavation and resource extraction. In-situ leaching excels in extracting metals from porous, permeable ore bodies, particularly in sedimentary environments with groundwater that can be controlled to mobilize minerals like uranium or copper. Comprehensive resource assessment incorporates ore deposit geometry, grade distribution, and hydrological properties to determine the optimal mining method for maximizing recovery and minimizing environmental impact.

Extraction Processes Compared

Open-pit mining involves physically removing large volumes of overburden to access mineral deposits, allowing direct extraction of ores with higher metal recovery rates. In-situ leaching employs chemical solutions injected into the ore body to dissolve minerals underground, minimizing surface disruption but often resulting in slower and lower yield extraction. The choice between these methods depends on ore type, depth, environmental impact, and economic feasibility, with open-pit preferred for shallow, massive deposits and in-situ leaching favored for permeable, low-grade ores.

Environmental Impact Analysis

Open-pit mining significantly alters landscapes, generating large volumes of waste rock and tailings that can lead to soil erosion and water contamination with heavy metals and toxic chemicals. In contrast, in-situ leaching minimizes surface disturbance by dissolving minerals underground and pumping the solution to the surface, reducing habitat destruction but posing risks of groundwater contamination through chemical leakage. Environmental impact assessments highlight that open-pit mining has higher greenhouse gas emissions and long-term ecosystem disruption, while in-situ leaching demands stringent monitoring to prevent aquifer pollution and ensure sustainable water management.

Economic Considerations and Cost Efficiency

Open-pit mining demands significant capital investment in equipment, labor, and site preparation, leading to higher upfront costs but offers economies of scale for large ore bodies. In-situ leaching features lower initial expenses and reduced environmental disturbance, translating to cost efficiency in extracting minerals from low-grade or deep deposits. Economic viability hinges on ore grade, deposit depth, and market price fluctuations, where in-situ leaching minimizes operational costs while open-pit mining maximizes yield potential.

Ore Recovery Rates and Selectivity

Open-pit mining achieves high ore recovery rates by physically extracting large volumes of ore, allowing precise selectivity in targeting ore bodies. In-situ leaching offers lower ore recovery rates but enhances selectivity by dissolving minerals directly in the ore body, reducing waste extraction. The choice between methods depends on ore grade, geology, and environmental considerations, with open-pit favoring high recovery and in-situ leaching optimizing selective mineral recovery.

Mine Site Rehabilitation and Closure

Open-pit mining requires extensive land disturbance, leading to significant environmental impacts that complicate mine site rehabilitation, often involving soil replacement, recontouring, and re-vegetation to restore ecosystems. In-situ leaching minimizes surface disruption by injecting leaching solutions underground, resulting in lower surface contamination and faster closure processes, but demands rigorous groundwater monitoring and remediation to prevent long-term pollution. Effective closure strategies for both methods emphasize minimizing ecological footprints, ensuring water quality, and complying with regulatory frameworks for sustainable post-mining landscapes.

Health and Safety in Operations

Open-pit mining poses significant health and safety risks due to exposure to dust, heavy machinery, and potential slope failures, increasing the likelihood of accidents and respiratory issues among workers. In-situ leaching offers a safer alternative by minimizing physical excavation and reducing direct human exposure to hazardous environments, thus lowering the incidence of occupational injuries and airborne contaminants. Effective monitoring of chemical use and groundwater contamination is crucial in in-situ leaching to ensure environmental and worker safety compliance.

Regulatory Compliance and Permitting

Open-pit mining faces stringent regulatory compliance requirements due to significant environmental impacts, including land disturbance, habitat destruction, and water contamination risks, necessitating comprehensive permitting and environmental impact assessments. In-situ leaching typically encounters fewer regulatory hurdles because it involves minimal surface disturbance and lower ecological disruption, but still requires strict monitoring and permits related to groundwater protection and chemical use. Regulatory agencies prioritize water resource management and site rehabilitation in permitting processes for both methods to ensure long-term environmental sustainability.

Future Trends and Technological Innovations

Open-pit mining is increasingly integrated with autonomous haulage systems and real-time drone surveying to enhance operational efficiency and reduce environmental impact. In-situ leaching benefits from advancements in bioleaching microbes and precision monitoring technologies, enabling more sustainable extraction of metals with minimal surface disruption. Emerging trends emphasize digital twin simulations and AI-driven process optimization to improve resource recovery and minimize ecological footprint in both mining methods.

Related Important Terms

Block caving variability

Open-pit mining offers predictable block caving variability due to the visible ore body, facilitating efficient extraction planning, whereas in-situ leaching presents higher uncertainty in block caving due to fluid flow dynamics and ore permeability variations. The variability in block caving efficiency directly impacts recovery rates, operational costs, and environmental footprint for both mining methods.

Heap leach pads

Open-pit mining involves excavating large volumes of rock to access ore deposits, often requiring extensive heap leach pads for processing low-grade ores by irrigating them with leaching solutions to extract valuable metals. In contrast, in-situ leaching bypasses traditional excavation by injecting solvents directly into ore bodies underground, minimizing surface disturbance and eliminating the need for heap leach pads.

Geochemical migration

Open-pit mining often results in extensive geochemical migration through the exposure of large rock surfaces to weathering, leading to acid mine drainage and mobilization of heavy metals into surrounding soils and water. In-situ leaching minimizes surface disturbance by injecting leaching solutions underground, reducing surface geochemical migration but potentially causing localized groundwater contamination through the movement of dissolved minerals.

Solution mining yield

Open-pit mining typically yields higher immediate ore extraction rates by physically removing large volumes of material, whereas in-situ leaching offers selective mineral recovery through solvent injection, resulting in lower but more sustainable solution mining yield. The efficiency of in-situ leaching depends on ore permeability and chemical reagent effectiveness, often producing less environmental impact compared to open-pit operations.

Pit slope optimization

Pit slope optimization in open-pit mining significantly enhances operational safety and cost-efficiency by balancing slope angle and stability to prevent collapses and reduce waste removal. In contrast, in-situ leaching eliminates the need for pit slopes altogether by extracting minerals directly from ore bodies through fluid circulation, minimizing surface disturbance and slope-related risks.

Hydrogeological fracturing

Open-pit mining involves extensive excavation and surface disturbance, significantly altering hydrogeological conditions and potentially causing fracturing in surrounding rock formations. In contrast, in-situ leaching relies on injecting leaching solutions to dissolve minerals underground, minimizing physical fracturing but posing risks of groundwater contamination through hydrogeological pathways.

Pregnant leach solution (PLS)

Open-pit mining generates large volumes of ore requiring extensive crushing and processing, whereas in-situ leaching produces Pregnant Leach Solution (PLS) directly by circulating lixiviant through the ore body, minimizing surface disturbance. The PLS contains dissolved metals that are pumped to the surface for recovery, offering a cost-effective and environmentally efficient alternative to traditional mining methods.

Solvent extraction-electrowinning (SX-EW)

Open-pit mining involves excavating large surface pits to extract ore, while in-situ leaching dissolves minerals underground using chemical solutions; Solvent extraction-electrowinning (SX-EW) is commonly integrated with in-situ leaching to efficiently recover metals such as copper by separating and electrowinning the metal from the leachate. SX-EW offers environmental benefits and cost savings by eliminating the need for traditional smelting and reducing surface disturbance compared to open-pit mining.

Acid rock drainage modeling

Open-pit mining generates significant volumes of exposed waste rock prone to acid rock drainage (ARD), demanding complex geochemical modeling to predict acidification and metal leaching over time. In-situ leaching minimizes surface disturbance, reducing ARD risk by limiting rock exposure, but requires detailed hydrogeological and geochemical models to manage potential acid generation and contaminant transport within groundwater systems.

Continuous groundwater monitoring

Continuous groundwater monitoring in open-pit mining involves extensive surface water management and real-time quality analysis to prevent contamination from exposed ores and waste rock. In contrast, in-situ leaching requires subsurface monitoring techniques to track leachate migration and maintain aquifer integrity, emphasizing the importance of sensor networks and predictive modeling for environmental safety.

Open-pit mining vs In-situ leaching Infographic

industrydif.com

industrydif.com