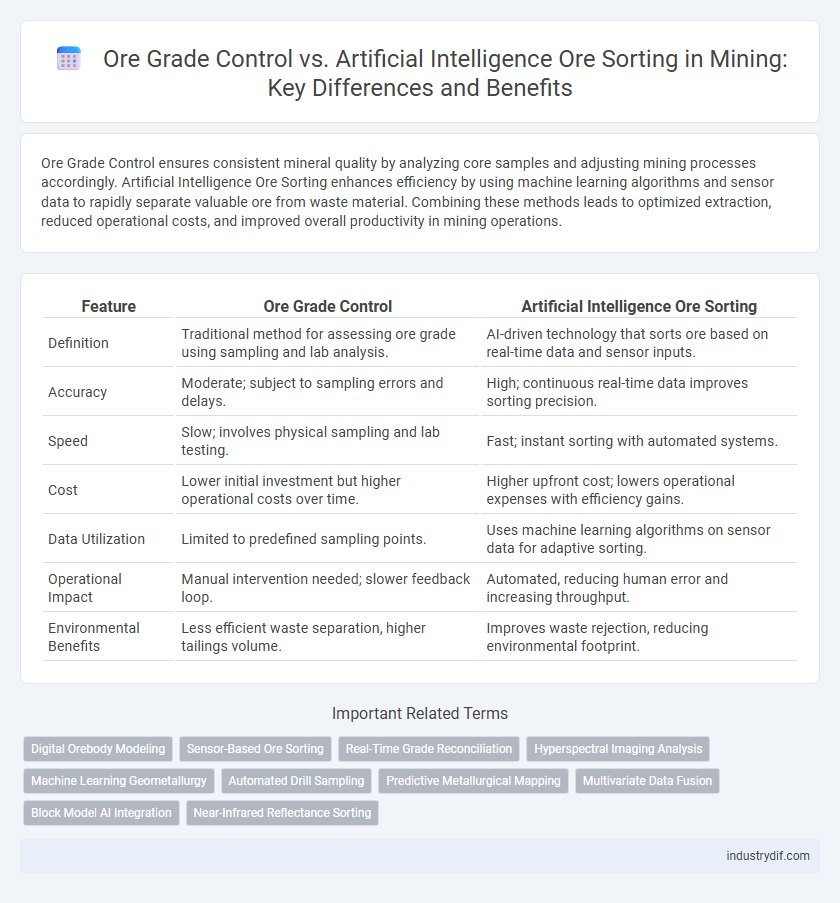

Ore Grade Control ensures consistent mineral quality by analyzing core samples and adjusting mining processes accordingly. Artificial Intelligence Ore Sorting enhances efficiency by using machine learning algorithms and sensor data to rapidly separate valuable ore from waste material. Combining these methods leads to optimized extraction, reduced operational costs, and improved overall productivity in mining operations.

Table of Comparison

| Feature | Ore Grade Control | Artificial Intelligence Ore Sorting |

|---|---|---|

| Definition | Traditional method for assessing ore grade using sampling and lab analysis. | AI-driven technology that sorts ore based on real-time data and sensor inputs. |

| Accuracy | Moderate; subject to sampling errors and delays. | High; continuous real-time data improves sorting precision. |

| Speed | Slow; involves physical sampling and lab testing. | Fast; instant sorting with automated systems. |

| Cost | Lower initial investment but higher operational costs over time. | Higher upfront cost; lowers operational expenses with efficiency gains. |

| Data Utilization | Limited to predefined sampling points. | Uses machine learning algorithms on sensor data for adaptive sorting. |

| Operational Impact | Manual intervention needed; slower feedback loop. | Automated, reducing human error and increasing throughput. |

| Environmental Benefits | Less efficient waste separation, higher tailings volume. | Improves waste rejection, reducing environmental footprint. |

Introduction to Ore Grade Control in Mining

Ore grade control in mining involves systematically sampling and analyzing ore to ensure consistent quality and optimize extraction processes, directly influencing the economic viability of mining operations. Precise grade control relies on detailed geological modeling, real-time data acquisition, and laboratory assays to minimize dilution and maximize ore recovery. Integrating advanced technologies such as Artificial Intelligence and machine learning enhances ore sorting accuracy, automates decision-making, and reduces operational costs, driving improved resource efficiency.

Evolution of Ore Sorting: Traditional vs. Innovative Techniques

Ore grade control traditionally relied on manual sampling and laboratory assays to estimate ore quality, which was time-consuming and less precise. The evolution towards artificial intelligence ore sorting integrates real-time sensor data and machine learning algorithms to enhance accuracy and efficiency in separating valuable minerals from waste. Innovative AI-driven sorting techniques reduce operational costs, improve recovery rates, and enable adaptive decision-making in complex mining environments.

Defining Ore Grade Control: Methods and Limitations

Ore grade control involves systematically sampling and analyzing ore to determine metal content and distribution within a deposit, using methods such as drill core assays, blast hole sampling, and geostatistical modeling. Limitations include sampling bias, assay delays, and challenges in accurately capturing grade variability at fine scales, which can lead to suboptimal mine planning and metal recovery. Contrasting with AI ore sorting, traditional grade control relies heavily on physical sampling and analytical turnaround times rather than real-time data processing and automated material discrimination.

Artificial Intelligence in Ore Sorting: How It Works

Artificial Intelligence in ore sorting utilizes machine learning algorithms to analyze optical, X-ray, or hyperspectral data from mined material, enabling precise identification and separation of valuable ore from waste in real-time. Advanced sensors capture detailed mineralogical and textural features, while AI models continuously optimize sorting decisions to maximize recovery rates and reduce dilution. This non-destructive technology significantly enhances ore grade control by increasing throughput efficiency and lowering operational costs compared to traditional manual sampling methods.

Comparing Efficiency: Manual Grade Control vs. AI-Powered Sorting

Manual ore grade control relies heavily on periodic sampling and laboratory analysis, which can introduce delays and reduce real-time accuracy in mineral processing. In contrast, AI-powered ore sorting utilizes advanced sensors and machine learning algorithms to rapidly classify and separate ore based on chemical composition, significantly enhancing efficiency and reducing waste. This automation not only improves throughput but also optimizes resource allocation by ensuring higher precision in grade control throughout the mining operation.

Impact on Resource Recovery and Waste Reduction

Ore grade control improves resource recovery by precisely mapping mineral distribution, enabling selective mining and minimizing dilution. Artificial intelligence ore sorting enhances waste reduction through real-time sensor data analysis, allowing automated separation of valuable ore from waste rock. Combining both technologies maximizes ore extraction efficiency and reduces environmental impact by limiting unnecessary processing of low-grade material.

Real-Time Data Analytics and Decision Making in Mining

Ore grade control relies on traditional sampling and laboratory assays, which often delay decision-making and reduce real-time responsiveness. Artificial intelligence ore sorting employs advanced sensors and machine learning algorithms to analyze mineral composition instantaneously, enabling dynamic adjustments in extraction processes. Real-time data analytics combined with AI-driven sorting enhances operational efficiency by optimizing ore quality and minimizing waste during mining operations.

Cost Implications: Traditional vs. AI-Based Ore Sorting

Traditional ore grade control involves extensive sampling and laboratory analysis, leading to high operational costs and time delays. AI-based ore sorting uses real-time sensor technology and machine learning algorithms to accurately classify ore, significantly reducing labor costs and increasing processing speed. The cost savings from AI implementation also include lower waste handling expenses and improved resource recovery, offering a more economical and efficient alternative to conventional methods.

Sustainability Benefits of AI in Ore Processing

Artificial intelligence (AI) ore sorting enhances ore grade control by significantly reducing waste and energy consumption during mineral processing, leading to more sustainable mining operations. AI-driven sorting systems improve resource efficiency by accurately separating valuable minerals from waste rock, minimizing the need for extensive milling and chemical usage. This precision lowers environmental impact, reduces greenhouse gas emissions, and promotes responsible resource management in the mining industry.

Future Trends: Integrating AI and Grade Control for Smarter Mining

Future trends in mining emphasize integrating AI ore sorting with traditional ore grade control to enhance accuracy and efficiency. AI algorithms analyze real-time data from ore grade control systems, enabling dynamic decision-making and optimized resource allocation. This synergy drives smarter mining operations, reducing waste and maximizing ore recovery.

Related Important Terms

Digital Orebody Modeling

Digital Orebody Modeling enhances ore grade control by integrating spatial data to accurately predict mineral distribution and optimize mining processes. Artificial Intelligence Ore Sorting complements this by enabling real-time, automated separation of valuable ore, increasing recovery rates and reducing waste through advanced sensor data analysis.

Sensor-Based Ore Sorting

Sensor-based ore sorting utilizes advanced imaging, hyperspectral, and X-ray sensors to enhance ore grade control by precisely identifying valuable minerals and rejecting waste material, thereby improving processing efficiency and reducing operational costs. Incorporating artificial intelligence algorithms further refines sensor data interpretation, enabling real-time decision-making and optimizing material flow based on ore heterogeneity and quality variations.

Real-Time Grade Reconciliation

Real-time grade reconciliation in ore grade control involves continuous monitoring and adjustment of ore quality data to optimize extraction efficiency. Artificial intelligence ore sorting enhances this process by employing machine learning algorithms and advanced sensors to accurately classify ore types instantly, significantly improving grade accuracy and operational throughput.

Hyperspectral Imaging Analysis

Ore grade control relies on traditional sampling and chemical assays to determine mineral concentrations, while artificial intelligence ore sorting utilizes hyperspectral imaging analysis to rapidly identify mineralogical variations at a submillimeter scale, enhancing sorting precision and reducing processing costs. Hyperspectral imaging combined with machine learning algorithms enables real-time differentiation of ore from waste materials by capturing spectral signatures beyond human vision, improving resource efficiency and operational productivity.

Machine Learning Geometallurgy

Machine learning in geometallurgy enhances ore grade control by enabling precise classification and prediction of ore variability, optimizing processing efficiency and recovery rates. Artificial intelligence ore sorting integrates sensor data with advanced algorithms to selectively separate high-grade ore pre-processing, reducing waste and operational costs while improving overall mine profitability.

Automated Drill Sampling

Automated drill sampling enhances ore grade control by providing continuous, real-time data on mineral composition, enabling precise resource estimation and reducing sampling errors. Artificial intelligence ore sorting further refines this process by analyzing spectral data to separate valuable ore from waste, optimizing mineral recovery and operational efficiency in mining.

Predictive Metallurgical Mapping

Predictive metallurgical mapping leverages AI ore sorting technologies to enhance ore grade control by providing real-time, high-precision data on mineral composition and variability, significantly improving extraction efficiency and reducing operational costs. Traditional ore grade control methods rely on periodic sampling and lab analysis, which often lag behind dynamic mine conditions, whereas AI-driven predictive models enable continuous optimization of processing parameters and resource allocation.

Multivariate Data Fusion

Ore grade control traditionally relies on geostatistical sampling and laboratory assays to ensure consistent mineral quality, while Artificial Intelligence ore sorting enhances precision by integrating multivariate data fusion from sensor arrays and real-time process variables. Leveraging machine learning algorithms on fused datasets optimizes ore characterization, reduces dilution, and increases recovery rates in mining operations.

Block Model AI Integration

Block model AI integration enhances ore grade control by providing real-time, high-resolution data analysis that improves the accuracy of mineral classification and resource estimation. This approach surpasses traditional ore grade control methods through automated pattern recognition and predictive modeling, optimizing ore sorting efficiency and reducing operational costs.

Near-Infrared Reflectance Sorting

Ore grade control traditionally relies on sampling and laboratory assays to determine mineral concentrations, ensuring consistent quality in mining operations, while artificial intelligence ore sorting using Near-Infrared Reflectance Sorting (NIRS) offers rapid, non-destructive analysis by detecting specific mineralogical signatures in real-time. NIRS combined with machine learning algorithms enhances precision in separating ore from waste, optimizing yield, and reducing processing costs by focusing on spectral data linked to mineral composition.

Ore Grade Control vs Artificial Intelligence Ore Sorting Infographic

industrydif.com

industrydif.com