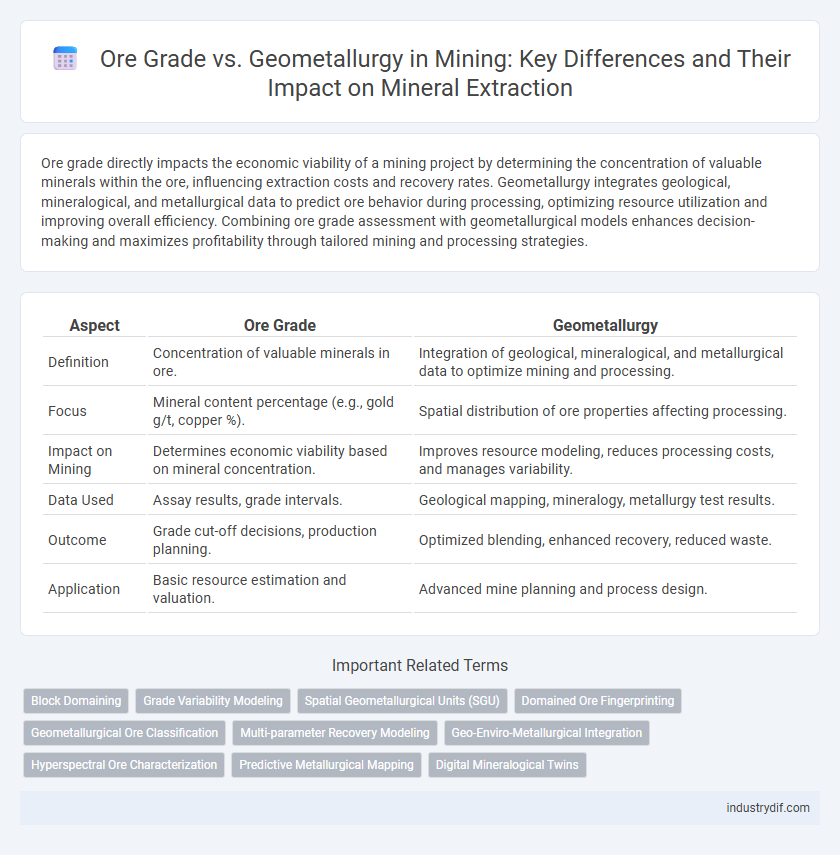

Ore grade directly impacts the economic viability of a mining project by determining the concentration of valuable minerals within the ore, influencing extraction costs and recovery rates. Geometallurgy integrates geological, mineralogical, and metallurgical data to predict ore behavior during processing, optimizing resource utilization and improving overall efficiency. Combining ore grade assessment with geometallurgical models enhances decision-making and maximizes profitability through tailored mining and processing strategies.

Table of Comparison

| Aspect | Ore Grade | Geometallurgy |

|---|---|---|

| Definition | Concentration of valuable minerals in ore. | Integration of geological, mineralogical, and metallurgical data to optimize mining and processing. |

| Focus | Mineral content percentage (e.g., gold g/t, copper %). | Spatial distribution of ore properties affecting processing. |

| Impact on Mining | Determines economic viability based on mineral concentration. | Improves resource modeling, reduces processing costs, and manages variability. |

| Data Used | Assay results, grade intervals. | Geological mapping, mineralogy, metallurgy test results. |

| Outcome | Grade cut-off decisions, production planning. | Optimized blending, enhanced recovery, reduced waste. |

| Application | Basic resource estimation and valuation. | Advanced mine planning and process design. |

Defining Ore Grade in Mining

Ore grade in mining quantifies the concentration of valuable minerals within a mineral deposit, directly impacting the economic feasibility of extraction. Geometallurgy integrates geological, mineralogical, and metallurgical information to predict ore behavior during processing, optimizing recovery rates. Understanding ore grade variations aids in designing efficient extraction methods and aligning them with geometallurgical models for enhanced operational performance.

Understanding Geometallurgy

Geometallurgy integrates geological, mineralogical, and metallurgical data to predict ore grade variability and optimize resource extraction. Understanding geometallurgy enables precise modeling of ore behavior during processing, improving recovery rates and reducing operational costs. This approach bridges the gap between ore grade estimation and practical metallurgical performance, ensuring efficient mine planning and resource management.

The Relationship Between Ore Grade and Geometallurgy

Ore grade directly influences geometallurgical models by determining the spatial distribution of valuable minerals and their processing characteristics. Geometallurgy integrates ore grade data with geological, mineralogical, and metallurgical information to optimize extraction methods and predict metal recoveries accurately. Understanding the relationship between ore grade and geometallurgy enhances resource estimation, processing efficiency, and economic evaluation of mining projects.

Importance of Ore Grade in Resource Evaluation

Ore grade directly influences the economic viability of mining projects by determining the concentration of valuable minerals within the ore body. Geometallurgy integrates ore grade data with mineralogical and geotechnical properties to optimize extraction processes and improve resource evaluation accuracy. Accurate ore grade assessment within geometallurgical models enhances prediction of metallurgical performance and supports sustainable mine planning.

Geometallurgical Modeling Techniques

Geometallurgical modeling techniques integrate geological, mineralogical, and metallurgical data to predict ore behavior during processing, enhancing ore grade assessment accuracy. Methods such as 3D spatial modeling, machine learning algorithms, and geostatistical analysis improve resource characterization by correlating ore grade with mineral recovery and processing performance. These advanced models optimize mine planning and enhance operational efficiency by reducing variability and uncertainty in ore grade estimation.

Impact of Ore Grade Variability on Processing

Ore grade variability significantly influences geometallurgical modeling by affecting mineral liberation and metallurgical recovery rates, leading to fluctuations in processing efficiency and operational costs. Accurate characterization of ore grade through geometallurgical data enables optimized mill settings and reagent usage, reducing energy consumption and maximizing metal recovery. Integrating ore grade variability into processing simulations enhances prediction accuracy, thereby improving throughput management and economic performance in mining operations.

Integrating Geometallurgy in Mine Planning

Integrating geometallurgy in mine planning enhances ore grade prediction accuracy, allowing for more efficient resource allocation and processing strategies. By combining geological, mineralogical, and metallurgical data, geometallurgical models provide detailed spatial variability of ore grade, optimizing extraction sequences and reducing operational costs. This approach ensures improved recovery rates and maximizes economic returns through targeted blending and processing tailored to specific ore characteristics.

Technological Advances in Ore Grade Assessment

Technological advances in ore grade assessment have transformed geometallurgy by integrating real-time sensor data with advanced machine learning algorithms, enabling more precise and rapid determination of mineral composition and grade distribution within ore bodies. Innovations such as hyperspectral imaging, X-ray fluorescence (XRF), and automated drill core analysis optimize the spatial variability understanding, leading to improved resource estimation and mine planning. These enhanced assessment techniques reduce operational risks and increase extraction efficiency by tailoring processing methods to the specific characteristics of the ore.

Economic Implications of Ore Grade and Geometallurgy

Ore grade directly influences the economic viability of mining projects by determining the concentration of valuable minerals, affecting extraction costs and revenue potential. Geometallurgy integrates geological, mineralogical, and metallurgical data to optimize processing strategies, reducing operational risk and enhancing resource recovery. Combining high ore grade assessment with geometallurgical modeling maximizes profitability through improved mine planning and efficient resource utilization.

Future Trends in Ore Grade Analysis and Geometallurgical Integration

Innovations in ore grade analysis leverage machine learning algorithms and real-time sensor data to enhance predictive accuracy and operational efficiency. Geometallurgical integration combines geological, mineralogical, and metallurgical data to optimize ore processing and reduce operational costs. Future trends emphasize digital twin technology and advanced spatial modeling to enable dynamic resource characterization and adaptive mining strategies.

Related Important Terms

Block Domaining

Block domaining in geometallurgy enhances ore grade estimation by integrating spatial variability and mineralogical characteristics within geological models. This approach improves the precision of ore grade distribution predictions, optimizing mine planning and resource extraction strategies.

Grade Variability Modeling

Ore grade variability modeling in geometallurgy integrates spatial and compositional data to predict mineral distribution with enhanced accuracy, enabling optimized mine planning and processing strategies. Advanced geostatistical techniques such as kriging and machine learning algorithms refine grade estimation, reducing financial risk and improving resource recovery.

Spatial Geometallurgical Units (SGU)

Spatial Geometallurgical Units (SGU) integrate ore grade variability with geological and metallurgical properties, enabling optimized resource modeling and extraction strategies in mining operations. By categorizing ore bodies based on mineralogical and textural characteristics alongside grade distribution, SGUs enhance predictive accuracy for processing performance and recovery rates.

Domained Ore Fingerprinting

Domained ore fingerprinting enhances ore grade prediction by integrating geometallurgical modeling, enabling precise characterization of mineralogical variability within ore bodies. This approach refines extraction strategies and maximizes resource efficiency through targeted ore processing based on spatially resolved ore quality data.

Geometallurgical Ore Classification

Geometallurgical ore classification integrates geological, mineralogical, and metallurgical data to optimize ore grade estimation and processing efficiency. This approach enables precise prediction of ore behavior during extraction, enhancing recovery rates and reducing operational costs in mining projects.

Multi-parameter Recovery Modeling

Multi-parameter recovery modeling in geometallurgy integrates ore grade variability with mineralogical and metallurgical characteristics to optimize extraction processes and enhance overall recovery rates. This approach enables precise prediction of process performance by linking ore grade distribution with geometallurgical domains, resulting in improved resource estimation and operational efficiency.

Geo-Enviro-Metallurgical Integration

Geo-enviro-metallurgical integration enhances ore grade evaluation by combining geological, environmental, and metallurgical data to optimize resource extraction and processing efficiency. This multidisciplinary approach enables precise prediction of ore quality variations, minimizing environmental impact while maximizing metal recovery and economic value.

Hyperspectral Ore Characterization

Hyperspectral ore characterization offers precise mineralogical mapping, enhancing the understanding of ore grade variability within geometallurgical models. Integrating hyperspectral data allows for accurate prediction of ore grade distribution, optimizing extraction strategies and processing efficiency in mining operations.

Predictive Metallurgical Mapping

Predictive metallurgical mapping enhances ore grade assessment by integrating geometallurgical data, enabling precise prediction of mineral processing behavior and optimizing extraction efficiency. Advanced modeling techniques correlate ore grade variability with geometallurgical parameters, improving resource evaluation and mine planning accuracy.

Digital Mineralogical Twins

Ore grade variability is critically analyzed through geometallurgy using Digital Mineralogical Twins, which integrate mineral identification, texture, and spatial data to optimize extraction processes. These digital models enable real-time predictions of ore behavior, enhancing resource efficiency and reducing operational risks in mining projects.

Ore grade vs Geometallurgy Infographic

industrydif.com

industrydif.com