Room and pillar mining relies on creating a network of tunnels supported by pillars of untouched material to ensure stability, offering reliable extraction but limited efficiency in rock fragmentation. Electric pulse fragmentation utilizes high-voltage electrical pulses to induce rock breakage, significantly reducing mechanical wear and increasing fragmentation precision. This advanced method enhances resource recovery and operational safety compared to traditional room and pillar techniques.

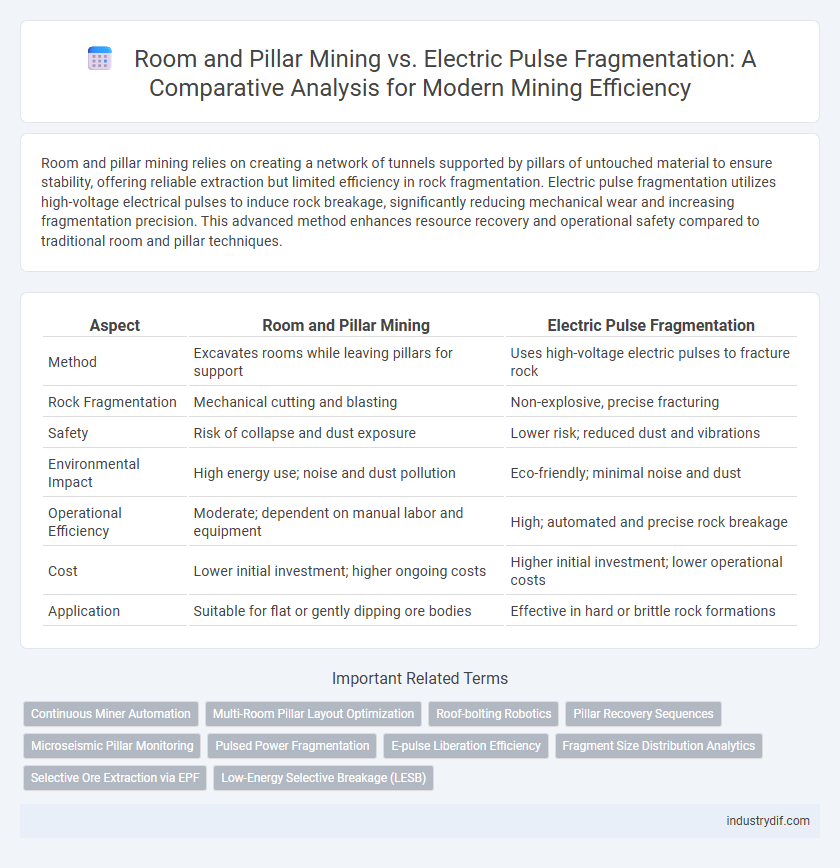

Table of Comparison

| Aspect | Room and Pillar Mining | Electric Pulse Fragmentation |

|---|---|---|

| Method | Excavates rooms while leaving pillars for support | Uses high-voltage electric pulses to fracture rock |

| Rock Fragmentation | Mechanical cutting and blasting | Non-explosive, precise fracturing |

| Safety | Risk of collapse and dust exposure | Lower risk; reduced dust and vibrations |

| Environmental Impact | High energy use; noise and dust pollution | Eco-friendly; minimal noise and dust |

| Operational Efficiency | Moderate; dependent on manual labor and equipment | High; automated and precise rock breakage |

| Cost | Lower initial investment; higher ongoing costs | Higher initial investment; lower operational costs |

| Application | Suitable for flat or gently dipping ore bodies | Effective in hard or brittle rock formations |

Introduction to Mining Methods

Room and pillar mining involves excavating a series of rooms while leaving pillars of untouched material to support the roof, widely used in flat-lying ore deposits such as coal seams. Electric pulse fragmentation utilizes high-voltage electrical discharges to create fractures in rock, offering a non-explosive alternative that reduces seismic impact and improves selective extraction. Both methods optimize mineral recovery but differ in operational approach, environmental impact, and suitability depending on deposit characteristics and safety requirements.

Overview of Room and Pillar Mining

Room and pillar mining is a conventional underground mining method involving the excavation of horizontal tunnels (drifts) and leaving behind pillars of ore to support the roof. This technique is commonly used for flat-lying ore bodies such as coal, limestone, and salt, allowing for efficient extraction while maintaining structural stability. Compared to electric pulse fragmentation, which uses high-voltage electrical discharges to break rock, room and pillar mining relies on mechanical cutting and blasting for ore recovery.

Fundamentals of Electric Pulse Fragmentation

Electric pulse fragmentation leverages high-voltage electrical discharges to create controlled fractures in rock, offering precise breakage without mechanical contact. This method reduces dust, vibrations, and energy consumption compared to traditional room and pillar mining, which relies on mechanical cutting and blasting. By inducing dielectric breakdown within the rock matrix, electric pulse fragmentation enhances fragmentation efficiency and improves safety in underground mining operations.

Comparative Efficiency of Ore Recovery

Room and pillar mining typically recovers 60 to 80 percent of ore, leaving significant quantities unmined to maintain structural stability. Electric pulse fragmentation enhances ore recovery by utilizing high-voltage electric discharges to create more precise rock breakage, potentially increasing recovery rates beyond 85 percent. This method reduces dilution and recovery loss, making it more efficient for extracting valuable ore compared to traditional room and pillar techniques.

Safety Considerations in Each Technique

Room and pillar mining prioritizes structural stability by leaving pillars of ore to support the roof, significantly reducing the risk of collapses but exposing workers to potential hazards from dust and equipment. Electric pulse fragmentation minimizes physical contact with explosives, thereby lowering the risk of accidental detonations and improving air quality due to less dust and fewer toxic fumes. Safety protocols in room and pillar mining emphasize ventilation and roof support, while electric pulse fragmentation relies on controlled energy discharges and remote operation to enhance worker protection.

Environmental Impact Assessment

Room and pillar mining generates significant amounts of dust and ground vibrations, leading to air quality degradation and potential habitat disruption. Electric pulse fragmentation reduces environmental impact by minimizing airborne particulates and eliminating explosive use, thus lowering noise pollution and vibrations. Environmental Impact Assessment highlights electric pulse fragmentation as a more sustainable alternative with reduced ecological footprint compared to traditional room and pillar mining.

Equipment and Technology Requirements

Room and pillar mining relies heavily on traditional equipment such as continuous miners, shuttle cars, and roof bolters to ensure structural stability and material extraction. Electric pulse fragmentation technology requires specialized high-voltage pulse generators and electrodes, enabling precise rock breakage without mechanical contact, reducing wear on equipment. The adoption of electric pulse fragmentation demands advanced electrical control systems and insulation materials to manage high energy pulses, contrasting with the robust, mechanical machinery utilized in room and pillar operations.

Cost Analysis and Economic Feasibility

Room and pillar mining incurs high labor and ventilation costs due to its reliance on manual excavation and extensive support structures, making it less economically feasible in low-grade ore deposits. Electric pulse fragmentation reduces operational expenses by minimizing drilling and blasting costs while enhancing fragmentation precision, leading to higher yield and lower energy consumption. Cost analysis reveals that electric pulse fragmentation offers improved economic feasibility for mines prioritizing efficiency and reduced environmental impact.

Applications and Suitability by Ore Type

Room and pillar mining is highly effective for flat-lying, uniform ore bodies such as coal and salt due to its stability and selective extraction process. Electric pulse fragmentation excels in brittle, hard rock ores like copper and gold by minimizing blasting vibrations and environmental impact. Both methods cater to different ore characteristics, with room and pillar favoring sedimentary deposits and electric pulse fragmentation suited for complex geological formations.

Future Trends in Mining Technology

Room and pillar mining remains a foundational technique in underground mining, valued for its safety and structural stability, but its future is increasingly influenced by automation and digital monitoring to improve efficiency. Electric pulse fragmentation represents an emerging technology that uses high-voltage electric pulses to fracture rock with minimal environmental impact and reduced energy consumption. Future trends in mining technology prioritize integrating electric pulse fragmentation with real-time data analytics and robotic systems to enhance precision, reduce operational costs, and minimize ecological footprints in mineral extraction.

Related Important Terms

Continuous Miner Automation

Room and pillar mining relies on manual or semi-automated continuous miners to extract coal by leaving pillars for roof support, while electric pulse fragmentation (EPF) enhances rock breaking efficiency by using high-voltage electric pulses to fracture the material, reducing mechanical stress on equipment. Continuous miner automation integrates advanced sensors, real-time data analytics, and remote operation to optimize productivity, safety, and energy consumption in room and pillar mining environments.

Multi-Room Pillar Layout Optimization

Multi-room pillar layout optimization in room and pillar mining enhances ore recovery and stability by systematically designing pillar sizes and spacing to balance extraction and ground support. Electric pulse fragmentation complements this by reducing rock hardness and improving breakage efficiency, enabling more precise and effective multi-room layouts with minimized dilution and increased safety.

Roof-bolting Robotics

Room and pillar mining utilizes roof-bolting robotics to enhance safety and structural stability by automating the installation of support bolts in underground tunnels. Electric pulse fragmentation offers a less invasive rock-breaking method that reduces the need for extensive roof support, potentially minimizing reliance on robotic roof-bolting systems.

Pillar Recovery Sequences

Room and pillar mining typically relies on systematic pillar recovery sequences to maintain ground stability while maximizing ore extraction, often leading to partial pillar sacrifice and potential subsidence risks. Electric pulse fragmentation enhances pillar recovery by precisely fracturing rock using high-voltage pulses, allowing for more controlled extraction, reduced dilution, and improved safety compared to conventional mechanical methods.

Microseismic Pillar Monitoring

Room and pillar mining utilizes microseismic pillar monitoring to assess stress distribution and detect potential pillar failures, enhancing safety and stability in underground operations. Electric pulse fragmentation complements this by reducing rock mass strength and improving fragmentation efficiency, which, combined with microseismic data, optimizes pillar design and minimizes seismic risks.

Pulsed Power Fragmentation

Pulsed Power Fragmentation revolutionizes mining by using high-energy electric pulses to break rock, offering greater precision and reduced environmental impact compared to traditional Room and Pillar mining that relies on mechanical cutting and blasting. This innovative technology enhances safety and ore recovery efficiency by minimizing vibrations and controlling fragmentation size without destabilizing surrounding pillars.

E-pulse Liberation Efficiency

Electric pulse fragmentation demonstrates significantly higher liberation efficiency compared to traditional room and pillar mining by precisely targeting rock breakage, reducing dilution and energy consumption. This innovative E-pulse technology enhances mineral recovery rates and operational sustainability through controlled fracturing and reduced mechanical crushing.

Fragment Size Distribution Analytics

Room and pillar mining typically results in larger, uneven fragment size distribution due to mechanical cutting, leading to increased processing and handling costs. Electric pulse fragmentation produces more uniform and finer fragment size distribution, enhancing downstream processing efficiency and reducing energy consumption in comminution stages.

Selective Ore Extraction via EPF

Room and pillar mining relies on creating a network of pillars to support the roof while extracting ore, which often results in lower selectivity and higher dilution. Electric pulse fragmentation (EPF) enhances selective ore extraction by precisely fracturing ore with controlled electrical discharges, minimizing waste rock disturbance and allowing for more efficient resource recovery.

Low-Energy Selective Breakage (LESB)

Room and pillar mining utilizes Low-Energy Selective Breakage (LESB) to efficiently extract coal by strategically leaving pillars for support, minimizing energy use and reducing environmental impact. Electric pulse fragmentation, employing LESB, offers precise rock breakage with lower energy consumption and less vibration compared to traditional blasting methods, enhancing safety and operational control.

Room and pillar mining vs Electric pulse fragmentation Infographic

industrydif.com

industrydif.com