Room and pillar mining involves creating a series of open spaces (rooms) supported by pillars of untouched material to maintain mine stability, optimizing resource recovery while ensuring worker safety. Electric pulse fragmentation uses high-voltage electric discharges to break rock with minimal vibrations and environmental impact, enhancing efficiency and reducing equipment wear compared to traditional blasting. Comparing the two, room and pillar emphasizes structural integrity and resource management, whereas electric pulse fragmentation prioritizes precise, eco-friendly rock breakage for selective mining.

Table of Comparison

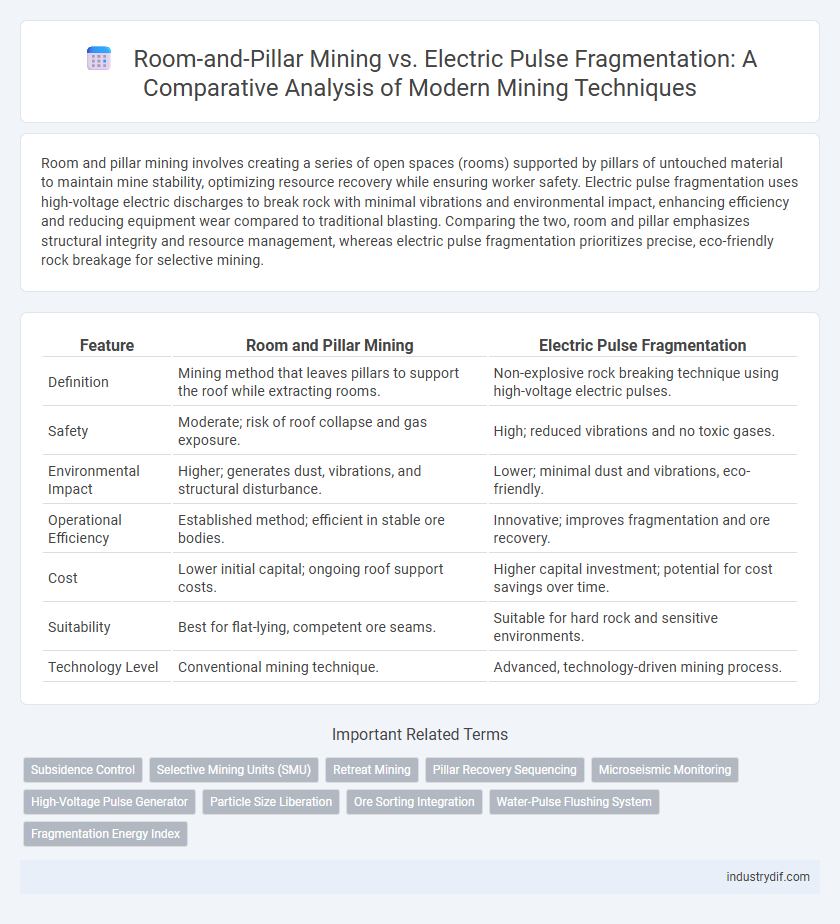

| Feature | Room and Pillar Mining | Electric Pulse Fragmentation |

|---|---|---|

| Definition | Mining method that leaves pillars to support the roof while extracting rooms. | Non-explosive rock breaking technique using high-voltage electric pulses. |

| Safety | Moderate; risk of roof collapse and gas exposure. | High; reduced vibrations and no toxic gases. |

| Environmental Impact | Higher; generates dust, vibrations, and structural disturbance. | Lower; minimal dust and vibrations, eco-friendly. |

| Operational Efficiency | Established method; efficient in stable ore bodies. | Innovative; improves fragmentation and ore recovery. |

| Cost | Lower initial capital; ongoing roof support costs. | Higher capital investment; potential for cost savings over time. |

| Suitability | Best for flat-lying, competent ore seams. | Suitable for hard rock and sensitive environments. |

| Technology Level | Conventional mining technique. | Advanced, technology-driven mining process. |

Introduction to Room and Pillar Mining

Room and pillar mining is a traditional underground mining method characterized by the creation of a grid of open spaces (rooms) supported by pillars of ore or rock to maintain roof stability. This technique is highly effective for extracting flat or gently dipping mineral deposits, particularly coal seams and certain metal ores, while minimizing surface subsidence. In contrast, electric pulse fragmentation is an emerging non-explosive rock breaking technology that utilizes high-voltage electric pulses to fracture rock with precision, reducing environmental impact and operational hazards.

Overview of Electric Pulse Fragmentation Technology

Electric Pulse Fragmentation (EPF) technology utilizes high-voltage electrical discharges to create fractures within rock masses, enabling efficient and selective rock breakage in mining operations. This method reduces mechanical wear and vibration compared to traditional room and pillar mining, enhancing safety and operational sustainability. EPF offers precise control over rock fragmentation, minimizing ore dilution and improving overall resource recovery.

Historical Development of Extraction Methods

Room and pillar mining originated in ancient civilizations, evolving through centuries as one of the earliest systematic underground extraction techniques for coal and minerals, while electric pulse fragmentation emerged in the late 20th century as a cutting-edge technology utilizing high-voltage electrical discharges to fracture rock without explosives. The historical development of room and pillar mining reflects gradual improvements in ventilation, roof support, and mechanization, enhancing safety and efficiency. Electric pulse fragmentation represents a transformative shift towards environmentally friendly and precise rock breaking, reducing blasting vibrations and improving ore recovery rates in modern mining operations.

Key Operational Principles: Room and Pillar

Room and pillar mining operates by excavating horizontal rooms while leaving pillars of untouched material to support the roof, ensuring structural stability during extraction. This method prioritizes controlled extraction with minimal ground disturbance and facilitates ventilation and safe movement within the mine. Key operational principles emphasize balance between ore recovery and maintaining pillar integrity to prevent collapses and maximize long-term mine safety.

Mechanisms of Electric Pulse Fragmentation

Electric pulse fragmentation in mining employs high-voltage electric discharges to induce dielectric breakdown and create micro-fractures within the rock mass, enabling precise and controlled rock breakage. Unlike traditional room and pillar mining, which relies on mechanical cutting and blasting, electric pulse techniques minimize mechanical stress and reduce seismic hazards by exploiting the electrical and dielectric properties of rocks. This mechanism enhances fragmentation efficiency, reduces energy consumption, and improves safety by limiting dust generation and vibration during the extraction process.

Comparative Energy Efficiency Analysis

Room and pillar mining typically exhibits higher energy consumption due to extensive drilling and blasting requirements, whereas electric pulse fragmentation leverages high-voltage electrical discharges to fracture rock with significantly lower energy input. Comparative studies indicate that electric pulse fragmentation can reduce energy usage by up to 40% compared to traditional mechanical methods, enhancing overall operational efficiency. The improved energy efficiency of electric pulse technology contributes to cost savings and reduced environmental impact in underground mining operations.

Safety and Environmental Considerations

Room and pillar mining offers enhanced safety by maintaining roof stability through strategically placed pillars, reducing collapse risks compared to more disruptive methods. Electric pulse fragmentation minimizes environmental impact by using high-voltage pulses to fracture rock without chemical explosives, leading to lower vibration, noise, and dust emissions. This technique also improves worker safety by reducing exposure to hazardous blasting materials and mechanical hazards.

Cost Implications and Economic Viability

Room and pillar mining requires substantial upfront capital investment in roof support systems and regular maintenance, leading to higher operational costs compared to electric pulse fragmentation. Electric pulse fragmentation reduces drilling and blasting expenses by minimizing explosive usage and enhancing rock breakage efficiency, improving overall cost-effectiveness. Economic viability of electric pulse fragmentation increases significantly in hard rock formations where traditional methods face high wear and downtime costs.

Application Suitability and Material Types

Room and pillar mining suits stable, flat-lying ore bodies like coal and salt, offering controlled extraction with minimal ground disturbance. Electric pulse fragmentation excels in hard, brittle materials such as granite and ores with complex mineralogy, providing precise breakage and reduced environmental impact. Selection depends on geological conditions and desired fragmentation efficiency, optimizing operational safety and resource recovery.

Future Trends in Hard Rock Mining Technologies

Room and pillar mining remains a reliable technique for stability and resource recovery in hard rock environments, but electric pulse fragmentation is gaining traction due to its ability to reduce environmental impact and improve fragmentation precision. Future trends indicate increased integration of electric pulse technology, driven by advancements in energy efficiency and automation, enhancing productivity while minimizing rock damage and seismic risks. Innovations in sensor technology and AI-driven control systems are expected to optimize the application of electric pulse fragmentation, revolutionizing hard rock mining operations.

Related Important Terms

Subsidence Control

Room and pillar mining maintains ground stability by leaving pillars of unmined material to support the roof, effectively controlling subsidence. Electric pulse fragmentation reduces stress on surrounding rock through controlled fracturing, minimizing ground deformation and enhancing subsidence control compared to traditional methods.

Selective Mining Units (SMU)

Room and pillar mining offers robust structural support by leaving pillars of intact material, optimizing selective mining units (SMU) for predictable unit extraction, whereas electric pulse fragmentation enhances selective mining by precisely fracturing rock with minimal damage to surrounding areas, improving SMU efficiency and ore recovery. Electric pulse fragmentation technology reduces dilution and increases ore grade control within SMUs, offering a cutting-edge alternative to conventional room and pillar methods for selective extraction.

Retreat Mining

Retreat mining in room and pillar method involves systematic extraction of pillars to maximize ore recovery while maintaining ground stability, contrasting with electric pulse fragmentation which uses high-voltage pulses to reduce rock damage and enhance fragment size control. Electric pulse fragmentation offers improved safety and reduced environmental impact during retreat mining by minimizing vibrations and dust compared to conventional pillar extraction techniques.

Pillar Recovery Sequencing

Room and pillar mining emphasizes systematic pillar recovery sequencing to maintain ground stability while maximizing ore extraction, using controlled removal patterns to reduce subsidence risks. Electric pulse fragmentation enhances this process by precisely fracturing rock around pillars, enabling more efficient ore recovery and minimizing damage to surrounding structures.

Microseismic Monitoring

Room and pillar mining generates continuous microseismic activity as pillars sustain stress redistribution, providing critical data for ground stability assessment; electric pulse fragmentation, by inducing controlled rock breakage, alters microseismic signatures enabling precise monitoring of induced fractures and rock behavior. Microseismic monitoring integrates real-time data from both methods to optimize excavation sequences, enhance safety protocols, and improve resource recovery efficiency.

High-Voltage Pulse Generator

Room and pillar mining relies on leaving pillars of ore to support the roof while extracting surrounding material, whereas electric pulse fragmentation uses a high-voltage pulse generator to create controlled rock breakage through electrical discharges, minimizing mechanical stress and enhancing ore recovery. The high-voltage pulse generator in electric pulse fragmentation offers increased precision, reduced environmental impact, and improved fragmentation efficiency compared to traditional room and pillar methods.

Particle Size Liberation

Room and pillar mining typically produces larger, less liberated particles requiring secondary fragmentation, while electric pulse fragmentation generates finer particle size liberation directly at the source. Enhanced liberation through electric pulse technology improves downstream recovery rates and reduces energy consumption in comminution processes.

Ore Sorting Integration

Room and pillar mining enables selective extraction while maintaining structural stability, optimizing ore grade during the initial mining phase. Electric pulse fragmentation enhances downstream ore sorting efficiency by creating cleaner breakage patterns, facilitating more precise separation of valuable minerals from waste rock.

Water-Pulse Flushing System

Room and pillar mining maintains structural stability by leaving pillars of ore, while electric pulse fragmentation utilizes high-voltage electric discharges to fracture rock with minimal vibration. The water-pulse flushing system in electric pulse fragmentation efficiently removes broken rock fragments and cools the electrodes, enhancing fragmentation precision and operational safety compared to traditional room and pillar techniques.

Fragmentation Energy Index

Room and pillar mining typically exhibits a higher Fragmentation Energy Index due to the mechanical breakage forces involved, whereas electric pulse fragmentation significantly lowers the energy index by using controlled electrical discharges to fracture rock with greater efficiency. This reduction in fragmentation energy translates to decreased operational costs and enhanced productivity in mining operations.

Room and pillar vs Electric pulse fragmentation Infographic

industrydif.com

industrydif.com