Room and pillar mining involves extracting ore while leaving pillars of untouched material to support the roof, making it ideal for flat or gently dipping ore bodies with good ground conditions. Sublevel stoping allows for more extensive ore extraction by creating large open stopes with multiple sublevels, suitable for steeply dipping, massive ore deposits but requiring advanced ground control techniques. Both methods balance safety, ore recovery, and operational costs based on ore body geometry and rock stability.

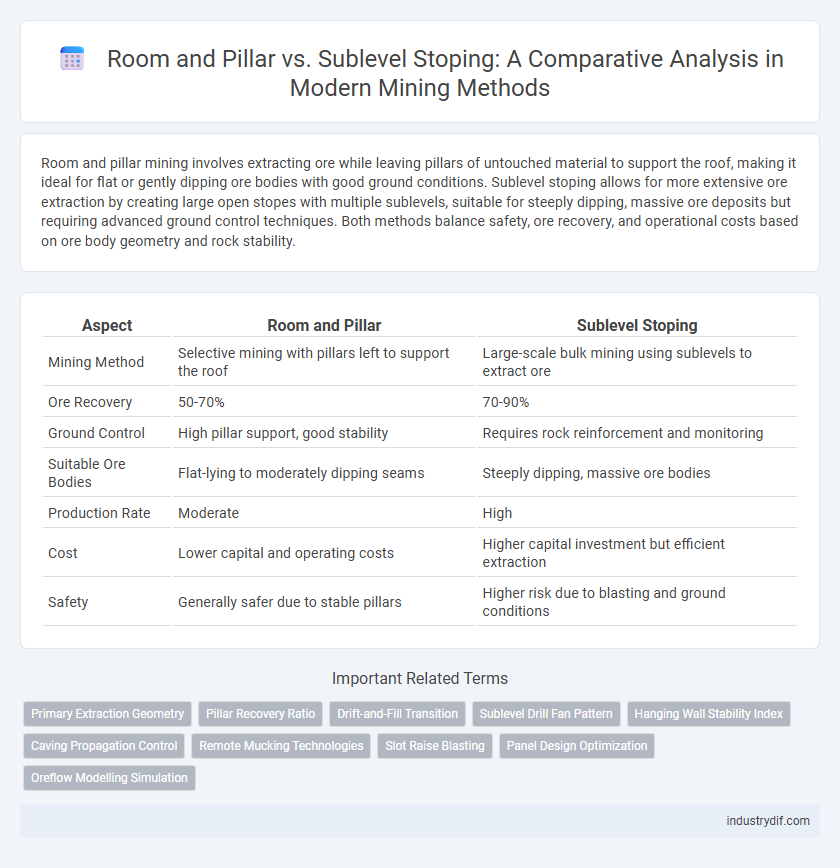

Table of Comparison

| Aspect | Room and Pillar | Sublevel Stoping |

|---|---|---|

| Mining Method | Selective mining with pillars left to support the roof | Large-scale bulk mining using sublevels to extract ore |

| Ore Recovery | 50-70% | 70-90% |

| Ground Control | High pillar support, good stability | Requires rock reinforcement and monitoring |

| Suitable Ore Bodies | Flat-lying to moderately dipping seams | Steeply dipping, massive ore bodies |

| Production Rate | Moderate | High |

| Cost | Lower capital and operating costs | Higher capital investment but efficient extraction |

| Safety | Generally safer due to stable pillars | Higher risk due to blasting and ground conditions |

Introduction to Underground Mining Methods

Room and pillar mining involves excavating horizontal rooms while leaving pillars of coal or ore to support the roof, offering safety and ease of access in flat or gently dipping deposits. Sublevel stoping, on the other hand, is a more mechanized method that extracts ore from vertical or steeply dipping ore bodies by drilling and blasting in sublevels, improving recovery but requiring robust ground control. Both methods are fundamental in underground mining, chosen based on ore body geometry, ground conditions, and production goals.

Fundamentals of Room and Pillar Mining

Room and pillar mining involves excavating horizontal tunnels while leaving pillars of ore to support the roof, providing stability and safety. This method is primarily used for flat-lying ore bodies, ensuring continuous extraction with minimal ground control requirements. Compared to sublevel stoping, room and pillar offers better ground support but lower extraction rates due to the ore left in pillars.

Sublevel Stoping: Key Features and Process

Sublevel stoping is a highly productive underground mining method characterized by the excavation of ore in horizontal slices or sublevels, which are developed at regular intervals within the ore body. This method enables efficient ore extraction with minimal dilution, employing large-scale drilling and blasting techniques to create open stopes supported by backfill or rock pillars. Its key features include the use of mechanized equipment such as load-haul-dump (LHD) machines and longhole drills, allowing for high production rates and effective ground control in steeply dipping ore bodies.

Geological Suitability for Each Method

Room and pillar mining is ideal for flat-lying, shallow deposits with strong, stable rock formations that can support pillars, minimizing collapse risk. Sublevel stoping suits steeply dipping, moderately to highly fractured ore bodies where ore can be efficiently blasted and removed in horizontal slices. Geological factors such as rock strength, dip angle, and ore continuity significantly influence the choice between these two mining methods.

Ore Recovery and Extraction Rates

Room and pillar mining typically achieves ore recovery rates of around 50-70% due to the need to leave pillars for ground support, limiting extraction efficiency. Sublevel stoping can reach higher ore recovery rates, often exceeding 80%, as it allows for more complete ore extraction with less support requirement. Extraction rates in sublevel stoping are generally faster and more continuous compared to the intermittent drilling and blasting cycles in room and pillar mining.

Safety Considerations: Room and Pillar vs Sublevel Stoping

Room and pillar mining offers enhanced safety by maintaining a network of pillars that support the overhead rock, reducing the risk of collapse and allowing for safer ventilation and escape routes. In contrast, sublevel stoping involves large, open stopes that can increase the potential for rock falls and require more intensive ground control measures to ensure worker safety. Safety considerations in room and pillar focus on pillar stability, while sublevel stoping demands rigorous monitoring and reinforcement to manage rock mass behavior.

Equipment and Technology Requirements

Room and pillar mining requires robust, continuous mining machines such as roof bolters and shuttle cars to maintain stability and efficient material transport, emphasizing safety equipment for roof support. Sublevel stoping demands advanced drilling rigs, mechanized loaders, and automated haulage systems to manage high production rates from large, vertical ore bodies, along with sophisticated ventilation and ground control technologies. Equipment selection in sublevel stoping prioritizes precision and scalability, while room and pillar mining focuses on operational reliability and structural integrity.

Operational Costs and Economic Factors

Room and pillar mining generally incurs lower operational costs due to simpler ventilation and ground support requirements, making it economically viable for flat-lying ore deposits with moderate depth. Sublevel stoping, while having higher operational costs from extensive drilling, blasting, and ore handling, offers greater extraction rates and is more cost-effective in high-grade, deep ore bodies. Economic factors such as ore grade, deposit geometry, and overall production scale critically influence the cost-benefit analysis between these two mining methods.

Environmental Impact Comparison

Room and pillar mining generally results in less surface subsidence and reduced ecosystem disturbance compared to sublevel stoping, as it leaves substantial support pillars intact underground. Sublevel stoping tends to create larger voids, increasing ground instability and potential for acid mine drainage, which negatively impacts surrounding water quality. The choice between these methods significantly influences local biodiversity preservation and long-term site reclamation feasibility.

Choosing the Right Method: Decision Criteria

Room and pillar mining offers a safer approach for flat or gently dipping ore bodies, maintaining ground stability through strategically spaced pillars, which suits high-value, less massive ore deposits. Sublevel stoping is preferred for steeply dipping, massive ore bodies with consistent grade distribution, enabling higher extraction rates but requiring robust ground control measures. Decision criteria emphasize ore body geometry, geotechnical conditions, economic factors, and safety considerations to optimize resource recovery and operational efficiency.

Related Important Terms

Primary Extraction Geometry

Room and pillar mining utilizes a geometric layout of wide, rectangular rooms supported by pillars left in place to maintain roof stability and facilitate primary extraction, optimizing safety and ore recovery. Sublevel stoping employs inclined ore drives and vertical or subvertical stopes with primary extraction geometry designed for efficient ore extraction through drilling and blasting in steeply dipping ore bodies.

Pillar Recovery Ratio

Room and pillar mining typically achieves a pillar recovery ratio of 40-60%, as pillars are left in place to support the mine roof, whereas sublevel stoping allows for higher recovery ratios of 70-90% by extracting more ore and minimizing pillars. The choice between these methods depends on ore body geometry, stability requirements, and desired recovery efficiency.

Drift-and-Fill Transition

Room and pillar mining involves excavating horizontal drifts or rooms while leaving pillars for support, suitable for flat or gently dipping deposits, whereas sublevel stoping targets steeply dipping ore bodies through sublevel development and longhole blasting. The drift-and-fill transition serves as a critical phase bridging these methods, where drift excavations progressively transition into filled stopes, optimizing ground control and ore recovery in steeply dipping mineralized zones.

Sublevel Drill Fan Pattern

Sublevel drill fan pattern in sublevel stoping enables precise ore extraction by drilling multiple angled holes from a single sublevel, enhancing fragmentation and ore recovery compared to the room and pillar method, which leaves pillars for ground support. This technique optimizes mineral recovery and improves safety by minimizing dilution and providing better control over ore boundaries in underground mining operations.

Hanging Wall Stability Index

Room and pillar mining generally exhibits a higher Hanging Wall Stability Index (HWSI) due to the preservation of pillars that support the hanging wall, reducing the likelihood of collapse. In contrast, sublevel stoping often results in a lower HWSI because the method involves large-scale ore extraction that can significantly destabilize the hanging wall, increasing rockfall risks.

Caving Propagation Control

Room and pillar mining provides enhanced caving propagation control by maintaining a network of pillars that support the roof and limit ground movement, reducing surface subsidence risks. Sublevel stoping, while offering higher ore recovery rates, presents challenges in caving control due to its reliance on induced fractures, which can propagate unpredictably and require precise sequencing to manage ground stability effectively.

Remote Mucking Technologies

Room and pillar mining utilizes remote mucking technologies to enhance safety and efficiency by allowing the extraction of ore without exposing workers to hazardous conditions. In contrast, sublevel stoping employs advanced remote mucking systems to manage large ore bodies with improved automation and precision, reducing operational downtime and increasing productivity.

Slot Raise Blasting

Slot raise blasting in room and pillar mining enhances controlled fragmentation and ventilation by creating precise vertical openings, promoting structural stability and ore extraction efficiency. In sublevel stoping, slot raise blasting is critical for establishing initial drawpoints and facilitating mucking cycles, supporting high production rates with improved safety compared to traditional methods.

Panel Design Optimization

Panel design optimization in room and pillar mining emphasizes systematic pillar sizing and layout to maximize ore recovery while ensuring ground stability. Sublevel stoping optimization focuses on precise sublevel spacing and stope dimensions to enhance fragmentation and minimize dilution, resulting in improved extraction efficiency.

Oreflow Modelling Simulation

Room and pillar and sublevel stoping exhibit distinct oreflow characteristics critical for simulation accuracy in mining operations. Oreflow modeling simulations reveal that room and pillar methods maintain more uniform ore extraction and stability, whereas sublevel stoping enables higher recovery rates but requires complex flow pattern adjustments for optimal material discharge.

Room and pillar vs Sublevel stoping Infographic

industrydif.com

industrydif.com