Tailings dams store mining waste in liquid form, posing significant environmental risks such as dam failure and water contamination. Dry stacking involves dewatering tailings to create a more stable, dry waste pile, reducing the risk of catastrophic failure and improving water management. This method enhances safety, lowers water usage, and promotes sustainable mining practices.

Table of Comparison

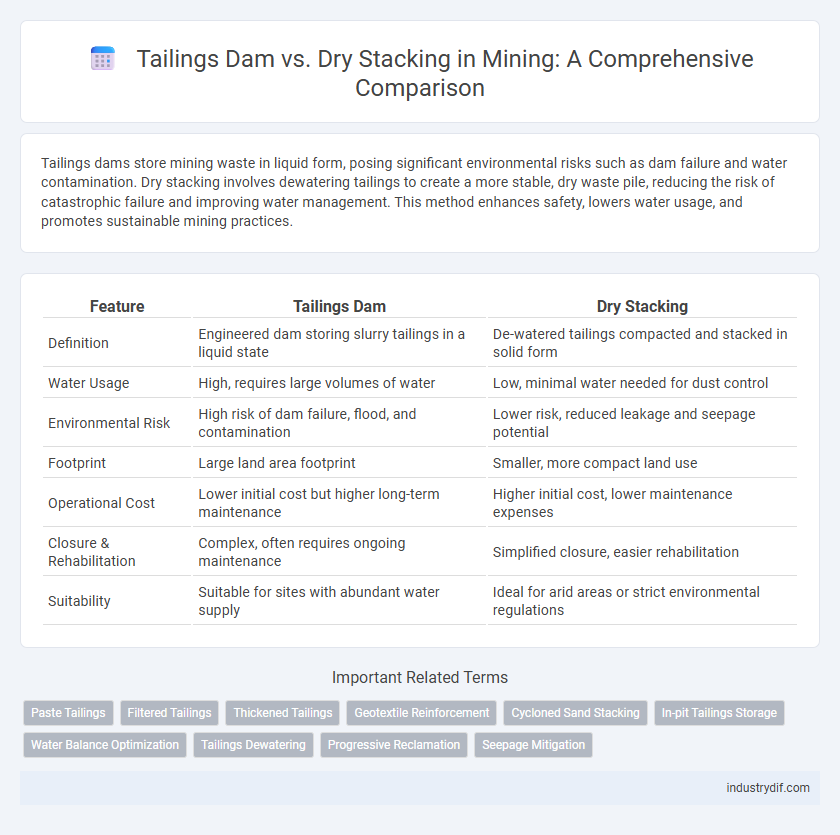

| Feature | Tailings Dam | Dry Stacking |

|---|---|---|

| Definition | Engineered dam storing slurry tailings in a liquid state | De-watered tailings compacted and stacked in solid form |

| Water Usage | High, requires large volumes of water | Low, minimal water needed for dust control |

| Environmental Risk | High risk of dam failure, flood, and contamination | Lower risk, reduced leakage and seepage potential |

| Footprint | Large land area footprint | Smaller, more compact land use |

| Operational Cost | Lower initial cost but higher long-term maintenance | Higher initial cost, lower maintenance expenses |

| Closure & Rehabilitation | Complex, often requires ongoing maintenance | Simplified closure, easier rehabilitation |

| Suitability | Suitable for sites with abundant water supply | Ideal for arid areas or strict environmental regulations |

Introduction to Tailings Management in Mining

Tailings management in mining involves controlling waste materials generated after ore extraction, with tailings dams and dry stacking as two primary disposal methods. Tailings dams store slurry waste as a liquid suspension, relying on large embankments to contain the material, while dry stacking dewaters tailings into a solid form for safer, more environmentally friendly storage. Effective tailings management prioritizes stability, environmental protection, and compliance with regulations to prevent catastrophic failures and minimize ecological impact.

Overview of Tailings Dams

Tailings dams are engineered structures designed to store byproducts of mining operations, consisting primarily of fine-grained slurry composed of water and leftover mineral particles. These dams are typically built from earth materials and rely on natural sedimentation to consolidate tailings, offering large-volume storage solutions but posing risks of structural failure and environmental contamination. Advances in tailings dam monitoring and management focus on improving stability, reducing seepage, and complying with international safety standards to mitigate ecological and human health impacts.

Dry Stacking: Definition and Process

Dry stacking is a tailings management method that involves dewatering mined waste material to create a stackable, solid form. The process begins with thickening tailings using filtration or centrifugation to reduce water content, allowing for safer, more stable storage. This technique minimizes environmental risks like dam failures and reduces water consumption compared to traditional tailings dams.

Environmental Impacts: Tailings Dams vs Dry Stacking

Tailings dams pose significant environmental risks including potential dam failure, water contamination, and long-term ecosystem disruption due to the accumulation of toxic slurry. Dry stacking minimizes environmental impacts by reducing water usage, eliminating the risk of catastrophic dam breaches, and enabling safer, more stable waste storage with improved rehabilitation potential. Regulatory frameworks increasingly favor dry stacking for its enhanced environmental safety and reduced footprint in mining waste management.

Water Usage and Recovery in Tailings Storage

Tailings dams require extensive water to maintain slurry consistency, resulting in significant water loss through evaporation and seepage, impacting local water resources. Dry stacking minimizes water usage by dewatering tailings before storage, enhancing water recovery rates and reducing environmental risks associated with water contamination. Efficient water management in tailings storage prioritizes dry stacking to conserve water and promote sustainable mining practices.

Safety and Risk Assessment

Tailings dam storage involves large impoundments of slurry which pose significant risks of catastrophic failure and environmental contamination due to potential dam breaches. Dry stacking minimizes risk by dewatering tailings to create stable, compacted stacks that reduce water seepage and the likelihood of dam collapse. Rigorous safety assessments favor dry stacking for reduced environmental hazards and improved structural stability in tailings management.

Cost Comparison: Initial and Long-term Investment

Tailings dam construction typically requires a lower initial investment compared to dry stacking due to simpler infrastructure and established methods, but long-term costs increase significantly from dam maintenance, water management, and potential environmental remediation. Dry stacking involves higher upfront capital expenses related to filtration technology and conveyor systems, yet it offers lower operational costs and reduced environmental liabilities over time. Cost-effectiveness depends on site-specific factors, including water availability, regulatory compliance, and risk management strategies in mining waste disposal.

Land Footprint and Site Rehabilitation

Tailings dam storage requires a significantly larger land footprint compared to dry stacking, which compacts tailings into a smaller, more stable volume. Dry stacking enables faster site rehabilitation since the dry material is easier to manage, reducing risks of seepage and dam failure. Land reclamation proceeds more efficiently with dry stacking due to its lower environmental impact and improved structural stability.

Regulatory and Community Considerations

Tailings dam construction faces stringent regulatory scrutiny due to risks of catastrophic failures and environmental contamination, necessitating continuous monitoring and emergency response plans. Dry stacking, favored for its reduced water usage and lower risk of seepage, often receives stronger community support for minimizing potential environmental hazards and improving local safety. Regulatory frameworks increasingly incentivize dry stacking adoption through stricter permitting processes and enhanced stakeholder engagement requirements.

Future Trends in Tailings Disposal Technologies

Future trends in tailings disposal technologies emphasize the shift from conventional tailings dams to dry stacking methods, which reduce environmental risks and improve stability. Innovations such as sensor-based monitoring and automated stacking systems are enhancing the safety and efficiency of dry stacking operations. Increasing regulatory pressure and sustainability goals are driving mining companies to adopt these advanced technologies to minimize water usage and mitigate potential dam failures.

Related Important Terms

Paste Tailings

Paste tailings technology offers enhanced stability and reduced environmental impact compared to conventional tailings dam storage, leveraging high solids content to minimize free water. Dry stacking further improves tailings management by dewatering tailings for solid storage, but paste tailings optimize rheological properties to enable efficient pipeline transport and controlled placement, reducing risk of dam failure.

Filtered Tailings

Filtered tailings, a key component of dry stacking, significantly reduce environmental risks by minimizing water use and enhancing dam stability compared to traditional tailings dams, which pose higher failure hazards due to water retention in impoundments. Dry stacking enables safer waste management through dewatered, compacted tailings, improving site rehabilitation and reducing the footprint of mining operations.

Thickened Tailings

Thickened tailings technology enhances solids concentration from 30-50% to 60-70%, reducing water content and improving storage stability compared to traditional tailings dams. This method minimizes environmental risks by decreasing seepage and dam failure potential while optimizing water recovery and reducing footprint in dry stacking applications.

Geotextile Reinforcement

Tailings dam construction relies heavily on geotextile reinforcement to stabilize embankments, prevent erosion, and control seepage, enhancing the structural integrity of wet tailings storage. In contrast, dry stacking employs geotextiles primarily to improve drainage and reinforce soil layers in compacted tailings, reducing water content and minimizing environmental risks.

Cycloned Sand Stacking

Cycloned sand stacking in tailings management offers a safer and more environmentally sustainable alternative to traditional tailings dams by reducing water usage and minimizing the risk of catastrophic dam failures. This method enhances the structural stability of tailings storage through the dewatering and stacking of sand-sized particles, which facilitates easier reclamation and improves overall mine site safety.

In-pit Tailings Storage

In-pit tailings storage combines the benefits of tailings dams and dry stacking by depositing filtered tailings directly into mined-out pits, enhancing storage efficiency and reducing surface footprint. This method minimizes environmental risks associated with conventional tailings dams while optimizing water recovery and improving geotechnical stability.

Water Balance Optimization

Tailings dam storage typically requires significant water retention and recycling systems to maintain the water balance, minimizing runoff and seepage risks. Dry stacking optimizes water balance by reducing water usage through dewatering processes, enabling more sustainable water management and lower environmental impact in mining operations.

Tailings Dewatering

Tailings dewatering is a critical process in mining that involves reducing moisture content in tailings, enhancing the stability and safety of tailings dams. Unlike dry stacking, which completely removes water to create a solid tailings deposit, tailings dewatering improves conventional tailings dams by minimizing seepage and reducing the risk of dam failure through partial water extraction.

Progressive Reclamation

Progressive reclamation in mining significantly reduces environmental impact by enabling tailings dam operators to rehabilitate land concurrently with tailings deposition, promoting safer storage and ecosystem restoration. Dry stacking enhances progressive reclamation by using filtered tailings that allow immediate compaction and vegetation, minimizing water usage and eliminating dam failure risks.

Seepage Mitigation

Tailings dams employ engineered liners and seepage collection systems to manage and reduce seepage, minimizing environmental contamination risks. Dry stacking significantly lowers seepage potential by dewatering tailings and compacting them into a stable, permeable mass, offering superior seepage mitigation compared to conventional tailings dams.

Tailings dam vs Dry stacking Infographic

industrydif.com

industrydif.com