Truck and Shovel Mining relies on manual operation of heavy machinery, requiring skilled operators to load and haul materials, which can lead to increased labor costs and safety risks. In contrast, Autonomous Haulage Systems (AHS) utilize automated trucks controlled by advanced software and sensors, enhancing efficiency, reducing human error, and enabling continuous operation. This shift toward AHS optimizes mine productivity, decreases operational costs, and improves safety standards in mining environments.

Table of Comparison

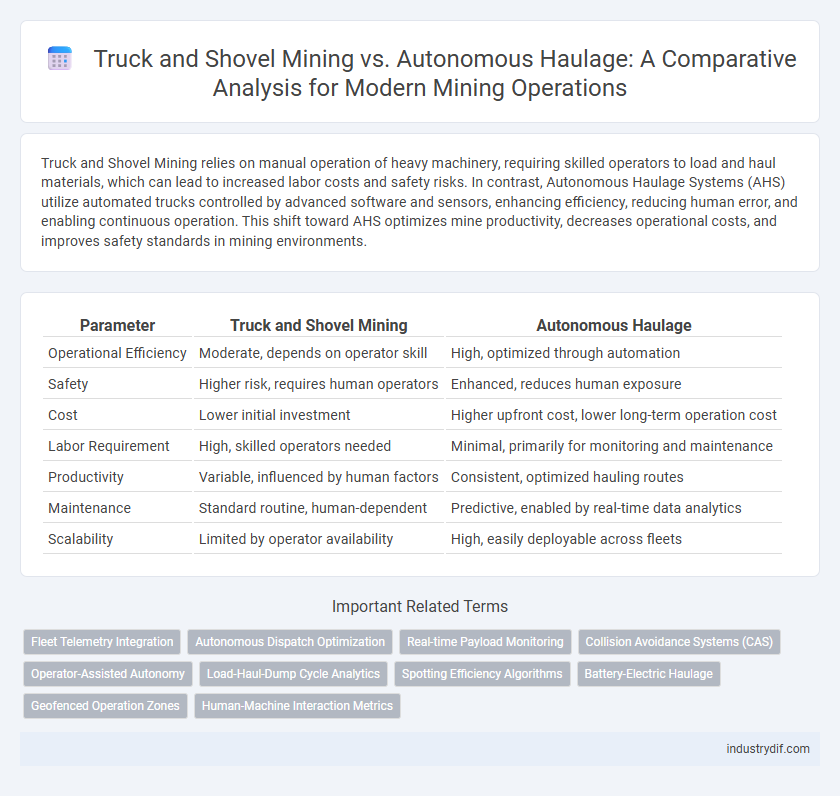

| Parameter | Truck and Shovel Mining | Autonomous Haulage |

|---|---|---|

| Operational Efficiency | Moderate, depends on operator skill | High, optimized through automation |

| Safety | Higher risk, requires human operators | Enhanced, reduces human exposure |

| Cost | Lower initial investment | Higher upfront cost, lower long-term operation cost |

| Labor Requirement | High, skilled operators needed | Minimal, primarily for monitoring and maintenance |

| Productivity | Variable, influenced by human factors | Consistent, optimized hauling routes |

| Maintenance | Standard routine, human-dependent | Predictive, enabled by real-time data analytics |

| Scalability | Limited by operator availability | High, easily deployable across fleets |

Overview of Truck and Shovel Mining Methods

Truck and shovel mining methods involve using large hydraulic shovels to excavate material, which is then loaded into haul trucks for transportation to processing sites. This traditional approach offers flexibility in varying terrain and orebody conditions while allowing precise control over excavation depth and pit design. Despite increasing adoption of autonomous haulage systems, truck and shovel operations remain essential for complex mining environments requiring manual oversight and adaptability.

Introduction to Autonomous Haulage Systems

Autonomous Haulage Systems (AHS) revolutionize mining operations by enabling trucks to operate without human drivers, enhancing safety and efficiency in truck and shovel mining environments. These systems utilize advanced sensors, GPS, and AI algorithms to navigate and transport materials with precision, reducing operational costs and minimizing downtime. Integration of AHS accelerates productivity by optimizing haul routes and improving fleet management in large-scale open-pit mining.

Operational Efficiency: Manual vs Autonomous

Truck and shovel mining traditionally relies on manual operations, which can result in variable operational efficiency due to human error and slower cycle times. Autonomous haulage systems enhance operational efficiency by providing consistent, optimized truck routing and precise shovel loading, reducing downtime and fuel consumption. Data from leading mines indicate autonomous fleets achieve up to 15-20% higher productivity and 10-15% lower operational costs compared to manual truck and shovel operations.

Safety Enhancements with Autonomous Haulage

Autonomous haulage systems significantly enhance safety in mining operations by reducing human exposure to hazardous environments and minimizing the risk of accidents caused by operator error. These systems use advanced sensors, GPS, and real-time data analytics to detect obstacles and maintain optimal navigation, improving overall site safety. Compared to traditional truck and shovel mining, autonomous haulage enables continuous monitoring and rapid response to potential safety threats, leading to a safer and more efficient mining process.

Cost Comparison: Labor and Maintenance

Truck and Shovel Mining incurs higher labor costs due to the need for multiple operators per truck and shovel, whereas Autonomous Haulage Systems (AHS) significantly reduce labor expenses by enabling remote or unsupervised operations. Maintenance costs in traditional Truck and Shovel Mining include frequent manual inspections and repairs caused by operator variability, while AHS usage lowers maintenance expenses through predictive analytics and consistent operational performance. Overall, Autonomous Haulage offers substantial cost savings by optimizing workforce allocation and minimizing unplanned downtime through advanced monitoring technologies.

Environmental Impact Analysis

Truck and shovel mining typically results in higher greenhouse gas emissions due to diesel fuel consumption and inefficient hauling routes. Autonomous haulage systems optimize truck dispatch and reduce fuel usage, lowering carbon footprints and minimizing dust generation in mining operations. Implementing autonomous haulage also decreases noise pollution and soil disturbance compared to traditional truck and shovel methods.

Fleet Management and Optimization

Truck and shovel mining requires intensive fleet management to coordinate numerous vehicles and equipment, ensuring efficient loading and haulage cycles. Autonomous haulage systems optimize fleet utilization through real-time data analytics, reducing idle time and improving fuel efficiency. Advanced algorithms in autonomous fleets provide predictive maintenance and dynamic route planning, enhancing overall mining productivity.

Technological Infrastructure Requirements

Truck and shovel mining demands robust communication networks and real-time monitoring systems to coordinate heavy machinery and ensure safety. Autonomous haulage systems require advanced sensor arrays, AI-driven control units, and high-precision GPS technology to enable driverless operation and optimize route efficiency. Both approaches depend heavily on reliable data infrastructure but autonomous haulage intensifies requirements for cybersecurity and machine learning integration.

Barriers to Adoption and Implementation

Truck and shovel mining faces barriers such as high labor costs and safety risks, while autonomous haulage systems encounter challenges including substantial upfront capital investment, complex integration with existing infrastructure, and regulatory compliance. The transition to autonomous haulage demands skilled workforce training and overcoming resistance to technology adoption within mining operations. Additionally, data security concerns and the need for reliable connectivity in remote mine sites further impede smooth implementation of autonomous haulage systems.

Future Trends in Mining Haulage Technologies

Future trends in mining haulage technologies emphasize the integration of autonomous haulage systems (AHS) with advanced truck and shovel mining operations, enhancing efficiency and safety. The adoption of AI-driven autonomous trucks reduces labor costs and minimizes human error, while real-time data analytics optimize shovel-truck dispatch and cycle times. Innovations such as electrification of haul trucks and remote operation centers further accelerate the shift toward sustainable, fully autonomous mining environments.

Related Important Terms

Fleet Telemetry Integration

Fleet telemetry integration in truck and shovel mining enables real-time monitoring of equipment performance and location, optimizing dispatch and maintenance processes for enhanced operational efficiency. Autonomous haulage systems leverage advanced fleet telemetry data to enable precise coordination and automation of trucks, reducing downtime and improving fuel efficiency across mining operations.

Autonomous Dispatch Optimization

Autonomous haulage systems leverage real-time data and AI-driven algorithms to optimize dispatch, significantly improving efficiency and reducing operational costs compared to traditional truck and shovel mining methods. Advanced autonomous dispatch optimization enables precise coordination of haulage routes and equipment utilization, enhancing productivity and minimizing downtime in large-scale mining operations.

Real-time Payload Monitoring

Real-time payload monitoring enhances Truck and Shovel Mining efficiency by providing instant data on load weights, reducing overloading risks and optimizing cycle times. Autonomous Haulage Systems leverage real-time payload data combined with AI to dynamically adjust routes and loading processes, maximizing productivity while minimizing fuel consumption and equipment wear.

Collision Avoidance Systems (CAS)

Truck and Shovel Mining relies heavily on manual or semi-automated operations, which increases the risk of collisions due to human error, whereas Autonomous Haulage leverages advanced Collision Avoidance Systems (CAS) utilizing lidar, radar, and AI algorithms to detect and prevent potential accidents proactively. These CAS technologies enhance operational safety by providing real-time spatial awareness and automatic braking, significantly reducing downtime and improving overall efficiency in mining haulage operations.

Operator-Assisted Autonomy

Operator-assisted autonomy in truck and shovel mining enhances productivity by integrating human oversight with automated haulage technologies, optimizing load and cycle times while maintaining safety standards. This hybrid approach leverages real-time operator input to address complex terrain and unexpected obstacles, improving operational efficiency compared to fully autonomous systems.

Load-Haul-Dump Cycle Analytics

Truck and shovel mining relies on manual load-haul-dump cycle analytics to optimize equipment utilization and reduce fuel consumption, whereas autonomous haulage systems leverage real-time data and AI-driven cycle analysis to enhance precision in load timing, haulage routes, and dump efficiency. Advanced cycle analytics in autonomous haulage enable predictive maintenance and dynamic scheduling, significantly improving overall operational productivity and minimizing downtime in large-scale mining operations.

Spotting Efficiency Algorithms

Truck and Shovel Mining relies on manual spotting efficiency algorithms, which often result in suboptimal loading cycles and increased downtime due to human error and communication delays. Autonomous Haulage systems leverage advanced AI-driven spotting efficiency algorithms that optimize truck positioning in real-time, significantly reducing loading times and improving overall operational throughput in mining sites.

Battery-Electric Haulage

Battery-electric haulage in truck and shovel mining significantly reduces greenhouse gas emissions and operational costs compared to traditional diesel-powered trucks. Autonomous battery-electric vehicles enhance efficiency and safety by optimizing haul cycles and minimizing human error in mining operations.

Geofenced Operation Zones

Truck and Shovel Mining relies on manual operation within defined geofenced zones to enhance safety and operational control, while Autonomous Haulage Systems leverage geofenced operation areas integrated with GPS and sensor technology to enable precise navigation and real-time monitoring. Geofenced zones in autonomous mining facilitate optimized route planning, reduce collision risks, and enhance productivity by enforcing strict boundaries for vehicle movement.

Human-Machine Interaction Metrics

Truck and shovel mining relies heavily on direct human-machine interaction, where operator skill influences efficiency, safety, and productivity metrics such as cycle time and load accuracy. Autonomous haulage systems optimize these human-machine interaction metrics by reducing operator fatigue, improving task consistency, and enabling real-time data feedback for predictive maintenance and operational decision-making.

Truck and Shovel Mining vs Autonomous Haulage Infographic

industrydif.com

industrydif.com