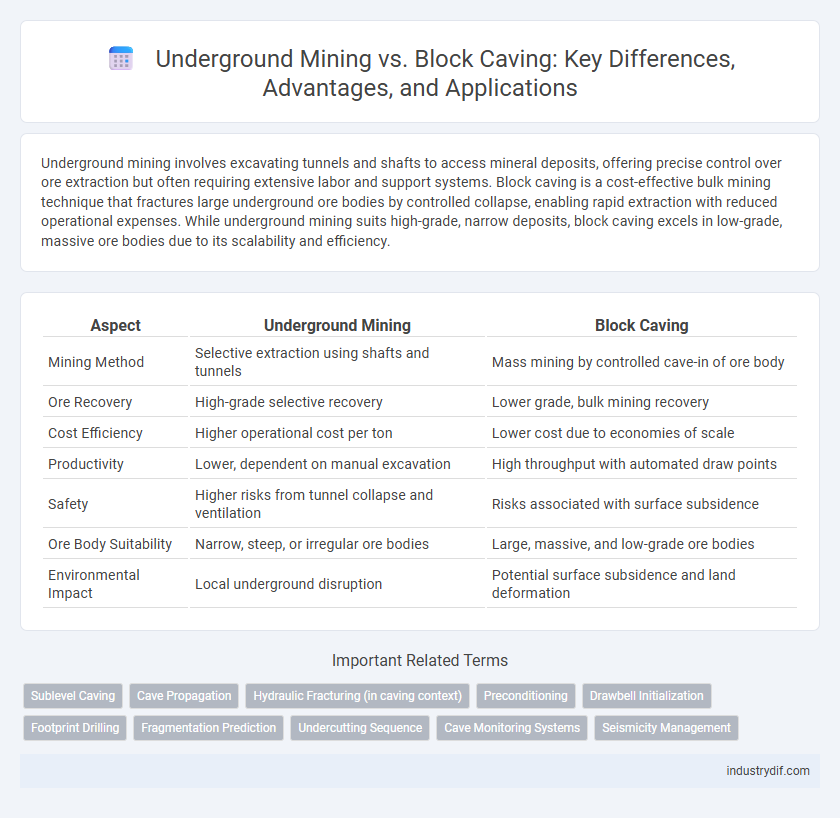

Underground mining involves excavating tunnels and shafts to access mineral deposits, offering precise control over ore extraction but often requiring extensive labor and support systems. Block caving is a cost-effective bulk mining technique that fractures large underground ore bodies by controlled collapse, enabling rapid extraction with reduced operational expenses. While underground mining suits high-grade, narrow deposits, block caving excels in low-grade, massive ore bodies due to its scalability and efficiency.

Table of Comparison

| Aspect | Underground Mining | Block Caving |

|---|---|---|

| Mining Method | Selective extraction using shafts and tunnels | Mass mining by controlled cave-in of ore body |

| Ore Recovery | High-grade selective recovery | Lower grade, bulk mining recovery |

| Cost Efficiency | Higher operational cost per ton | Lower cost due to economies of scale |

| Productivity | Lower, dependent on manual excavation | High throughput with automated draw points |

| Safety | Higher risks from tunnel collapse and ventilation | Risks associated with surface subsidence |

| Ore Body Suitability | Narrow, steep, or irregular ore bodies | Large, massive, and low-grade ore bodies |

| Environmental Impact | Local underground disruption | Potential surface subsidence and land deformation |

Overview of Underground Mining Methods

Underground mining methods include techniques such as room and pillar, cut and fill, and sublevel stoping, each designed to efficiently extract ore from beneath the surface with minimal surface disruption. Block caving is a large-scale underground mining method that involves undermining an ore body, causing it to collapse under its own weight, enabling mass extraction of low-grade, massive ore deposits. Compared to traditional underground methods, block caving offers high production rates and lower operating costs but requires substantial initial capital investment and precise geotechnical planning.

Introduction to Block Caving

Block caving is an underground mining method that involves undermining an ore body, causing it to collapse under its own weight and allowing fractured rock to be collected below. This technique efficiently exploits large, low-grade ore deposits that are otherwise uneconomical to mine with traditional underground methods. Compared to conventional underground mining, block caving offers higher production rates and lower operational costs, making it suitable for expansive mineral deposits.

Key Differences Between Underground Mining and Block Caving

Underground mining involves accessing ore deposits through tunnels and shafts with selective extraction, resulting in higher operational costs and safety risks due to the confined environment. Block caving is a mass mining method that uses controlled collapse of ore bodies, enabling large-scale and cost-effective extraction but with less precision and higher ore dilution. Key differences include the scale of production, extraction selectivity, safety considerations, and economic efficiency, with block caving favoring high-volume, low-grade ore bodies compared to selective underground mining targeting high-grade veins.

Geological Suitability for Each Method

Underground mining is best suited for high-grade, narrow ore bodies where selective extraction is critical, typically in hard rock geology with stable ground conditions. Block caving requires large, massive ore bodies with lower-grade mineralization and competent overlying rock to allow controlled caving and subsidence. The geological structure, ore grade distribution, and rock mechanics significantly influence the choice between underground mining and block caving methods.

Equipment and Technology Used

Underground mining commonly utilizes drills, loaders, and haulage trucks equipped with automated controls to enhance precision and safety in narrow tunnels. Block caving employs large-scale drawbells, conveyors, and remote-operated rock breakers to efficiently manage massive ore extraction through controlled rock collapse. Advanced sensor systems and real-time monitoring technologies are integrated in both methods to optimize operational efficiency and ensure worker safety.

Production Rates and Scalability

Underground mining typically offers lower production rates due to smaller-scale operations and limited access to ore bodies, making it suitable for high-grade, narrow veins. Block caving achieves significantly higher production rates by exploiting large, low-grade ore bodies through controlled collapse, enabling economies of scale and continuous extraction. Scalability in block caving surpasses conventional underground methods, as the large cave volume can be expanded to increase output without proportional increases in operational complexity.

Economic Considerations and Cost Analysis

Underground mining typically involves higher operational costs due to labor-intensive processes and slower ore extraction rates, whereas block caving offers lower per-ton extraction costs by leveraging gravity-driven ore collapse for bulk mining. Initial capital expenditure for block caving is substantial because of the required infrastructure, but it results in improved economies of scale and reduced unit costs over time. Economic considerations favor block caving in large, low-grade ore bodies with stable ground conditions, while conventional underground mining suits smaller, higher-grade deposits where flexibility is critical.

Environmental Impact Comparison

Underground mining typically disturbs less surface land but can cause significant subsidence and groundwater contamination, impacting local ecosystems. Block caving, a large-scale form of underground mining, often results in more extensive surface subsidence and altered hydrological systems due to the collapse of underground voids. Both methods emit greenhouse gases from diesel equipment and ore processing, but block caving's higher production rates can lead to increased overall environmental footprints if not managed with sustainable practices.

Safety Challenges and Risk Management

Underground mining and block caving each present unique safety challenges requiring specialized risk management strategies. Underground mining risks include tunnel collapses, gas explosions, and limited ventilation, necessitating rigorous monitoring and emergency response protocols. Block caving involves large-scale ground subsidence and rock fragmentation hazards, demanding continuous ground control assessments and advanced remote sensing technologies to ensure worker safety.

Future Trends in Underground Mining and Block Caving

Emerging technologies like automation, AI-driven orebody modeling, and advanced ventilation systems are transforming underground mining and block caving, enhancing safety and operational efficiency. Digital twin technology and real-time monitoring enable predictive maintenance and optimized resource extraction, reducing downtime and environmental impact. Future trends emphasize sustainable mining practices, integrating renewable energy sources and minimizing waste through improved ore recovery methods.

Related Important Terms

Sublevel Caving

Sublevel caving, a method within underground mining, involves systematic extraction through progressively mined sublevels, promoting controlled cave propagation and efficient ore recovery. This technique contrasts with block caving by offering more precise stope control and reduced surface subsidence, optimizing production in steeply dipping orebodies with complex geology.

Cave Propagation

Underground mining methods like block caving rely heavily on cave propagation, where controlled fracturing and collapse of rock layers facilitate ore extraction with minimal surface disruption. Effective cave propagation enhances productivity by enabling large-scale ore drawdown while maintaining ground stability throughout the mining operation.

Hydraulic Fracturing (in caving context)

Hydraulic fracturing in underground block caving enhances rock fragmentation by injecting high-pressure fluids to induce controlled fractures, improving ore recovery and reducing dilution compared to traditional underground mining methods. This technique optimizes cave propagation and stability, enabling more efficient material extraction and minimizing operational costs in large-scale subterranean mines.

Preconditioning

Preconditioning in underground mining involves techniques like hydraulic fracturing and blasting to weaken rock formations, enhancing fragmentation and stability. In block caving, preconditioning specifically targets creating controlled fractures to enable large-scale rock collapse, improving ore extraction efficiency and safety.

Drawbell Initialization

Drawbell initialization in block caving involves creating controlled underground voids that facilitate cave propagation by allowing ore to collapse naturally, enhancing mass extraction efficiency compared to traditional underground mining methods. Properly designed drawbells optimize fragment flow and reduce dilution, significantly impacting production rates and operational costs in subterranean mining projects.

Footprint Drilling

Underground mining utilizes targeted footprint drilling to create precise tunnels and stopes, minimizing surface disturbance and allowing selective ore extraction. Block caving, by contrast, employs extensive footprint drilling to induce controlled collapse over large ore bodies, maximizing ore recovery but increasing subsidence and surface footprint impact.

Fragmentation Prediction

Fragmentation prediction in underground mining relies on blast design parameters and geological conditions, whereas block caving utilizes natural rock mass fragmentation achieved through controlled caving and gravity, often resulting in larger fragmented material. Accurate fragmentation models enhance operational efficiency by optimizing mucking and crushing processes specific to each method's distinct rock breakage mechanisms.

Undercutting Sequence

The undercutting sequence in underground mining involves precise excavation at the base of the ore body to initiate controlled collapse, while in block caving, this sequence is a critical step to weaken the rock mass and promote gravity-driven ore fragmentation. Efficient undercutting ensures optimal fragmentation and material flow, directly impacting extraction rates and operational safety in both methods.

Cave Monitoring Systems

Underground mining employs cave monitoring systems that utilize microseismic sensors and ground deformation detectors to track rock mass behavior and ensure miner safety, while block caving integrates advanced real-time cave monitoring technologies such as fiber optic strain gauges and automated 3D imaging to optimize cave stability and ore recovery efficiency. These cave monitoring systems are critical for early detection of subsidence and rockfalls, enabling precise control of extraction processes in both mining methods.

Seismicity Management

Seismicity management in underground mining requires precise monitoring and control techniques to mitigate hazards associated with rock bursts and ground shaking. Block caving employs advanced seismic monitoring systems and controlled cave propagation to effectively manage induced seismic events, reducing safety risks compared to traditional underground mining methods.

Underground Mining vs Block Caving Infographic

industrydif.com

industrydif.com