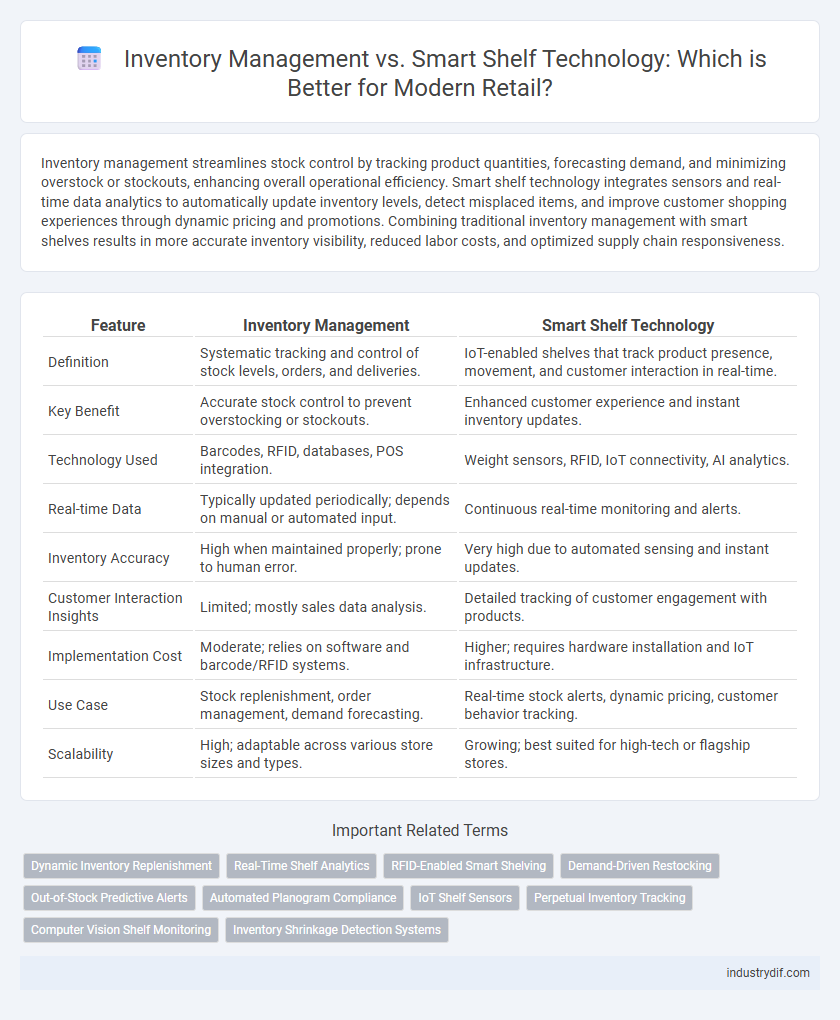

Inventory management streamlines stock control by tracking product quantities, forecasting demand, and minimizing overstock or stockouts, enhancing overall operational efficiency. Smart shelf technology integrates sensors and real-time data analytics to automatically update inventory levels, detect misplaced items, and improve customer shopping experiences through dynamic pricing and promotions. Combining traditional inventory management with smart shelves results in more accurate inventory visibility, reduced labor costs, and optimized supply chain responsiveness.

Table of Comparison

| Feature | Inventory Management | Smart Shelf Technology |

|---|---|---|

| Definition | Systematic tracking and control of stock levels, orders, and deliveries. | IoT-enabled shelves that track product presence, movement, and customer interaction in real-time. |

| Key Benefit | Accurate stock control to prevent overstocking or stockouts. | Enhanced customer experience and instant inventory updates. |

| Technology Used | Barcodes, RFID, databases, POS integration. | Weight sensors, RFID, IoT connectivity, AI analytics. |

| Real-time Data | Typically updated periodically; depends on manual or automated input. | Continuous real-time monitoring and alerts. |

| Inventory Accuracy | High when maintained properly; prone to human error. | Very high due to automated sensing and instant updates. |

| Customer Interaction Insights | Limited; mostly sales data analysis. | Detailed tracking of customer engagement with products. |

| Implementation Cost | Moderate; relies on software and barcode/RFID systems. | Higher; requires hardware installation and IoT infrastructure. |

| Use Case | Stock replenishment, order management, demand forecasting. | Real-time stock alerts, dynamic pricing, customer behavior tracking. |

| Scalability | High; adaptable across various store sizes and types. | Growing; best suited for high-tech or flagship stores. |

Understanding Inventory Management in Retail

Inventory management in retail involves tracking stock levels, orders, sales, and deliveries to ensure optimal product availability and reduce carrying costs. Smart shelf technology enhances inventory accuracy by using RFID sensors and real-time data analytics to monitor stock on shelves automatically. This integration minimizes stockouts and overstock situations, improving overall operational efficiency and customer satisfaction.

The Rise of Smart Shelf Technology

Smart shelf technology revolutionizes retail inventory management by providing real-time data through RFID sensors and weight detection systems, enabling precise stock monitoring and automatic replenishment alerts. This innovation reduces shrinkage, optimizes shelf space, and enhances customer experience by ensuring product availability and accurate pricing. Retailers adopting smart shelves achieve improved operational efficiency and data-driven decision-making compared to traditional manual inventory methods.

Key Differences: Traditional Inventory vs Smart Shelf Solutions

Traditional inventory management relies on manual stock counts and periodic audits, often leading to inaccuracies and delays in restocking. Smart shelf technology utilizes sensors and real-time data analytics to monitor product levels continuously, ensuring precise inventory tracking and automatic alerts for replenishment. This integration enhances operational efficiency, reduces stockouts, and improves customer satisfaction by maintaining optimal product availability.

Real-Time Inventory Tracking with Smart Shelves

Smart shelf technology revolutionizes real-time inventory tracking by using embedded sensors and RFID tags to monitor stock levels continuously. This technology reduces stockouts and overstock situations, enabling retailers to optimize inventory replenishment and improve operational efficiency. Integration with inventory management systems ensures accurate, up-to-the-minute data, enhancing demand forecasting and customer satisfaction.

Enhancing Stock Accuracy and Visibility

Inventory management systems optimize stock accuracy by leveraging real-time data tracking and automated replenishment alerts, reducing human error and stockouts. Smart shelf technology enhances visibility through sensors and RFID tags, providing instant updates on product levels and customer interactions. Integrating these technologies streamlines inventory control, enabling precise stock monitoring and improved demand forecasting in retail environments.

Impact on Shrinkage and Loss Prevention

Inventory management systems improve shrinkage control by providing real-time stock tracking and automated alerts for discrepancies, enabling faster detection of theft or errors. Smart shelf technology enhances loss prevention through embedded weight sensors and RFID tags, instantly identifying item removal or misplacement to reduce unnoticed shrinkage. Combining advanced inventory management with smart shelves creates a comprehensive approach that significantly minimizes inventory loss and improves overall retail security.

Cost Efficiency: Manual Inventory vs Automated Shelving

Manual inventory management often incurs higher labor costs and increased risk of human error, leading to inefficiencies and stock discrepancies. Smart shelf technology automates stock tracking through RFID sensors and real-time data analytics, significantly reducing labor expenses and minimizing out-of-stock situations. By optimizing stock levels and streamlining replenishment processes, automated shelving enhances cost efficiency and improves overall retail profitability.

Data Analytics: Leveraging Shelf Insights

Inventory management utilizes data analytics to track stock levels, forecast demand, and optimize replenishment cycles, improving overall supply chain efficiency in retail. Smart shelf technology incorporates sensors and RFID tags to provide real-time shelf insights, enabling dynamic inventory updates and minimizing stockouts or overstock situations. Leveraging shelf insights through advanced analytics allows retailers to enhance product availability, reduce shrinkage, and personalize customer experiences based on buying patterns.

Integration with POS and Supply Chain Systems

Integrating inventory management with POS and supply chain systems streamlines stock tracking and replenishment accuracy, reducing out-of-stock scenarios and excess inventory. Smart shelf technology enhances this integration by providing real-time data through weight sensors and RFID, enabling automated updates to inventory levels and immediate alerts for restocking. Combined, these technologies optimize operational efficiency, improve demand forecasting, and support seamless supply chain coordination in retail environments.

Choosing the Right Solution for Retail Success

Effective inventory management integrates real-time data analytics and automated tracking systems to minimize stockouts and overstock situations, enhancing overall retail efficiency. Smart shelf technology employs RFID sensors and IoT connectivity to provide accurate shelf-level inventory visibility, enabling dynamic pricing and personalized customer experiences. Selecting the appropriate solution depends on store size, product variety, and budget constraints, as combining both technologies can drive optimal retail performance and profitability.

Related Important Terms

Dynamic Inventory Replenishment

Dynamic inventory replenishment leverages smart shelf technology equipped with real-time sensors and RFID to automatically track stock levels and trigger timely restocking, reducing out-of-stock incidents and improving product availability. This integration streamlines inventory management by enabling precise demand forecasting and minimizing human error, thereby optimizing operational efficiency and enhancing the customer shopping experience.

Real-Time Shelf Analytics

Inventory management systems provide essential data on stock levels and product replenishment schedules, while smart shelf technology enhances accuracy through real-time shelf analytics, detecting product movement and stockouts instantly. Integrating smart shelves with inventory management optimizes supply chain efficiency, reduces shrinkage, and improves customer experience by ensuring product availability with up-to-the-minute insights.

RFID-Enabled Smart Shelving

RFID-enabled smart shelving revolutionizes inventory management by providing real-time tracking and automated stock replenishment, reducing human error and out-of-stock situations. This technology enhances retail efficiency by integrating RFID sensors into shelves, enabling instant data collection and seamless inventory updates compared to traditional manual methods.

Demand-Driven Restocking

Inventory management systems optimize stock levels by analyzing historical sales data and current demand patterns to ensure timely restocking. Smart shelf technology enhances demand-driven restocking by using sensors and real-time data analytics to automatically track inventory depletion and trigger replenishment alerts, reducing out-of-stock instances and improving supply chain responsiveness.

Out-of-Stock Predictive Alerts

Inventory management systems leverage historical sales data and demand forecasting algorithms to predict stock shortages, enabling retailers to avoid out-of-stock situations. Smart shelf technology integrates sensors and real-time data analytics, providing immediate alerts on inventory depletion and enhancing the accuracy of out-of-stock predictive alerts.

Automated Planogram Compliance

Automated planogram compliance through smart shelf technology enhances inventory management by continuously monitoring product placement and stock levels in real-time, reducing out-of-stock occurrences and improving shelf accuracy. This technology integrates RFID and sensors to ensure optimal product arrangement, streamlining retail operations and boosting sales performance.

IoT Shelf Sensors

IoT shelf sensors enhance inventory management by providing real-time stock monitoring, reducing out-of-stock incidents, and enabling automatic replenishment alerts. Unlike traditional inventory methods, smart shelf technology leverages data analytics and sensor integration to optimize supply chain efficiency and improve customer shopping experiences.

Perpetual Inventory Tracking

Perpetual inventory tracking enhances inventory management by providing real-time stock updates, reducing discrepancies and out-of-stock situations. Smart shelf technology automates this process with sensors and RFID tags, enabling accurate, continuous monitoring and optimized replenishment strategies in retail environments.

Computer Vision Shelf Monitoring

Computer Vision Shelf Monitoring enhances Inventory Management by providing real-time tracking of stock levels, reducing out-of-stock incidents and optimizing product placement. This technology leverages AI algorithms to analyze shelf images, enabling precise demand forecasting and automated restocking processes.

Inventory Shrinkage Detection Systems

Inventory shrinkage detection systems integrated with smart shelf technology utilize real-time sensors and RFID tags to accurately monitor stock levels and detect unauthorized removal or theft, significantly reducing inventory loss in retail environments. These advanced solutions surpass traditional inventory management methods by providing instant alerts and detailed analytics, enabling retailers to act swiftly and maintain optimal stock control.

Inventory Management vs Smart Shelf Technology Infographic

industrydif.com

industrydif.com