Planogram technology provides retailers with a visual guide to optimize product placement and maximize shelf space efficiency. Shelf-scanning robots enhance inventory accuracy by autonomously detecting stock levels and misplaced items in real-time. Combining planograms with shelf-scanning robots streamlines store operations and improves customer experience through better stock availability.

Table of Comparison

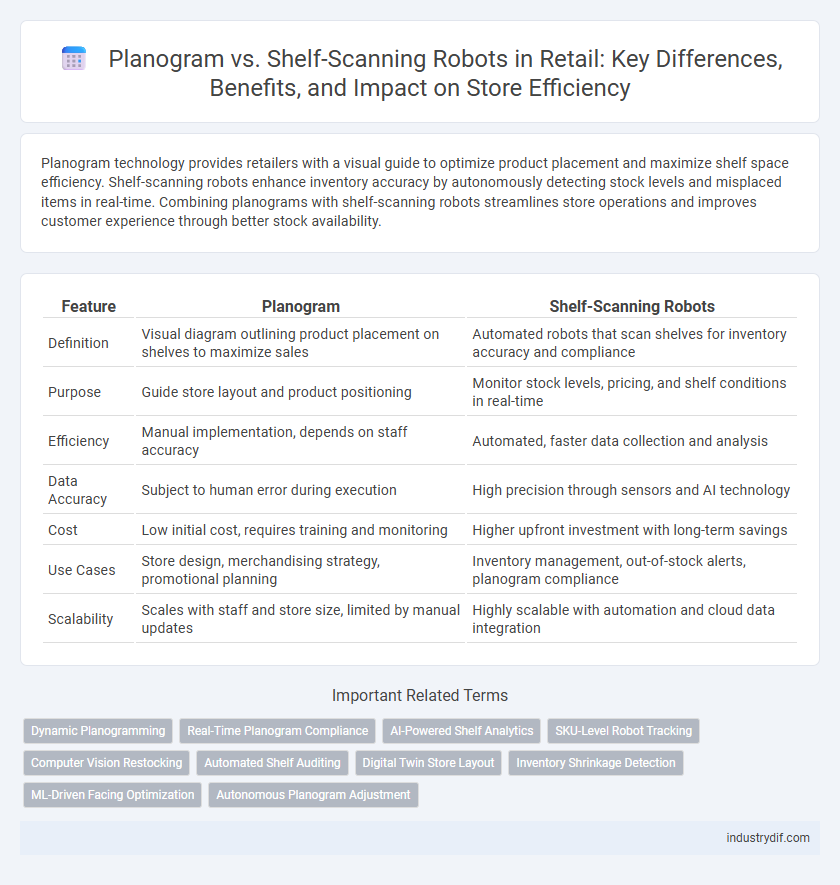

| Feature | Planogram | Shelf-Scanning Robots |

|---|---|---|

| Definition | Visual diagram outlining product placement on shelves to maximize sales | Automated robots that scan shelves for inventory accuracy and compliance |

| Purpose | Guide store layout and product positioning | Monitor stock levels, pricing, and shelf conditions in real-time |

| Efficiency | Manual implementation, depends on staff accuracy | Automated, faster data collection and analysis |

| Data Accuracy | Subject to human error during execution | High precision through sensors and AI technology |

| Cost | Low initial cost, requires training and monitoring | Higher upfront investment with long-term savings |

| Use Cases | Store design, merchandising strategy, promotional planning | Inventory management, out-of-stock alerts, planogram compliance |

| Scalability | Scales with staff and store size, limited by manual updates | Highly scalable with automation and cloud data integration |

Understanding Planograms in Retail

Planograms are detailed visual diagrams used in retail to optimize product placement on shelves, enhancing product visibility and maximizing sales. Shelf-scanning robots complement planograms by performing real-time inventory checks, ensuring adherence to the planogram layout and identifying out-of-stock or misplaced items. Integrating planogram strategies with shelf-scanning technology boosts operational efficiency and improves customer shopping experience through accurate shelf management.

The Rise of Shelf-Scanning Robots

Shelf-scanning robots are transforming retail by enhancing inventory accuracy and shelf compliance far beyond traditional planogram execution. These robots use AI-powered vision systems to detect out-of-stock items, pricing errors, and misplaced products in real time, enabling rapid corrective actions. Retailers implementing shelf-scanning technology report up to 30% improvement in inventory accuracy and increased sales due to better shelf availability and planogram adherence.

Efficiency Comparison: Manual Planograms vs Automated Robots

Manual planograms require intensive labor and frequent updates, often leading to human errors and inconsistent product placement that can negatively impact shelf efficiency. Automated shelf-scanning robots continuously monitor inventory and shelf compliance in real-time, providing precise data that enhances restocking speed and accuracy. Retailers implementing robots experience improved operational efficiency, reduced out-of-stock instances, and optimized shelf space utilization compared to traditional manual planogram management.

Data Accuracy: Human Insights vs AI-Driven Shelf Audits

Planogram compliance relies heavily on human insights that capture nuanced product placement preferences, while AI-driven shelf-scanning robots ensure precise, real-time data accuracy by automatically detecting stock levels, misplaced items, and pricing errors. Shelf-scanning robots enhance operational efficiency by reducing manual errors and providing consistent image recognition analysis across thousands of SKUs in retail environments. Combining human expertise with AI-generated shelf audits creates a comprehensive approach to inventory management and optimal product display strategies.

Implementation Costs and ROI Analysis

Planogram implementation involves initial expenses related to store layout design and employee training, with ROI realized through improved product placement and increased sales efficiency. Shelf-scanning robots require higher upfront investment in advanced hardware, software integration, and maintenance, but offer automated inventory tracking and real-time data for faster restocking and reduced out-of-stock instances. Comparing ROI, robots deliver long-term savings and operational accuracy, while planograms provide cost-effective visual merchandising solutions with quicker initial payback periods.

Impact on Inventory Management

Planogram technology enhances inventory management by providing precise product placement guidelines that optimize shelf space and improve stock visibility. Shelf-scanning robots complement this by autonomously auditing inventory levels, detecting stockouts, and identifying misplaced items in real time. Together, these systems significantly reduce inventory shrinkage and increase replenishment accuracy in retail environments.

Store Compliance: Planogram Adherence vs Robot Reporting

Planogram adherence ensures consistent product placement and visual merchandising that drives sales and improves customer experience. Shelf-scanning robots enhance store compliance by providing accurate, real-time inventory and placement data, identifying out-of-stock items and misplaced products efficiently. Combining planogram strategies with robot reporting enables retailers to optimize store operations, increase shelf visibility, and maintain higher compliance standards.

Employee Roles in the Age of Automation

Planogram development traditionally depends on retail employees for accurate product placement and inventory management, while shelf-scanning robots automate stock checks, enabling staff to focus on customer engagement and strategic tasks. Robots equipped with AI-driven sensors reduce manual labor and human error in inventory tracking, shifting employee roles toward technology supervision and exception handling. Embracing automation transforms workforce responsibilities, enhancing efficiency and allowing employees to contribute more to sales optimization and experiential retail.

Customer Experience: Consistency and Product Availability

Planogram compliance ensures consistent product placement, enhancing customer familiarity and ease of finding items, which boosts shopping satisfaction. Shelf-scanning robots provide real-time inventory data, minimizing out-of-stock situations and improving product availability. Together, these technologies optimize in-store experiences by maintaining organized shelves and ensuring products are consistently available.

Future Trends: Integrating Planograms with Robotics

Future trends in retail emphasize the integration of planograms with shelf-scanning robots to enhance inventory accuracy and optimize shelf space. Advanced AI-driven robots analyze planogram compliance in real-time, enabling dynamic adjustments and improved product placement. This synergy reduces stockouts, streamlines restocking processes, and drives higher sales through data-informed merchandising strategies.

Related Important Terms

Dynamic Planogramming

Dynamic planogramming leverages real-time data and AI to optimize product placement, enhancing shelf space efficiency and consumer engagement. Shelf-scanning robots complement this by continuously monitoring inventory levels and product positioning, enabling rapid adjustments to planograms for improved sales and reduced out-of-stock occurrences.

Real-Time Planogram Compliance

Planogram compliance is enhanced by shelf-scanning robots that use advanced sensors and AI to provide real-time inventory data and detect misplacements instantly. Unlike static planograms, these robots enable dynamic adjustments, improving on-shelf availability and customer shopping experience through continuous monitoring and immediate corrective actions.

AI-Powered Shelf Analytics

AI-powered shelf analytics leverage planogram compliance data to optimize product placement and inventory management, enhancing retail efficiency and shopper experience. Shelf-scanning robots use advanced computer vision and machine learning to detect out-of-stocks, misplaced items, and planogram deviations in real-time, driving actionable insights for store operations.

SKU-Level Robot Tracking

Planogram strategies optimize product placement to maximize shelf space efficiency, while shelf-scanning robots provide real-time SKU-level tracking by continuously monitoring inventory and ensuring precise stock counts. Integrating these technologies enhances retail operations by improving planogram compliance and reducing stockouts through accurate, automated shelf-level data collection.

Computer Vision Restocking

Planogram technology provides precise product placement guidelines based on sales data and consumer behavior, while shelf-scanning robots equipped with advanced computer vision systems continuously monitor inventory levels and identify out-of-stock items in real-time. These robots enhance restocking efficiency by automatically detecting misplaced products and shelf gaps, reducing human error and optimizing shelf space utilization in retail environments.

Automated Shelf Auditing

Automated shelf auditing leverages planogram data integrated with shelf-scanning robots to enhance inventory accuracy and compliance in retail environments. Shelf-scanning robots continuously capture real-time product placement and stock levels, enabling dynamic planogram adjustments and minimizing out-of-stock situations.

Digital Twin Store Layout

Digital Twin Store Layouts powered by planogram data enable precise simulation and optimization of retail shelf arrangements, enhancing inventory placement and shopper navigation. Shelf-scanning robots complement this by providing real-time inventory and compliance verification, ensuring that the digital twin aligns accurately with actual store conditions for improved retail efficiency.

Inventory Shrinkage Detection

Planogram compliance ensures optimal product placement but lacks real-time inventory shrinkage detection capabilities, whereas shelf-scanning robots use advanced sensors and AI to identify missing or misplaced items immediately. Integrating shelf-scanning robots in retail enhances inventory accuracy and reduces shrinkage by continuously monitoring stock levels and alerting staff to discrepancies.

ML-Driven Facing Optimization

Planogram design leverages historical sales data and machine learning algorithms to optimize product placement, enhancing visibility and maximizing shelf space efficiency. Shelf-scanning robots use real-time data and computer vision to continuously monitor stock levels and shelf compliance, enabling dynamic adjustments that align with ML-driven facing optimization strategies for improved retail performance.

Autonomous Planogram Adjustment

Shelf-scanning robots equipped with real-time data capture enable autonomous planogram adjustments by continuously monitoring product placement and stock levels to optimize shelf space and improve inventory accuracy. This automation reduces manual labor, enhances planogram compliance, and adapts dynamically to sales trends and consumer behavior for increased retail efficiency.

Planogram vs Shelf-Scanning Robots Infographic

industrydif.com

industrydif.com