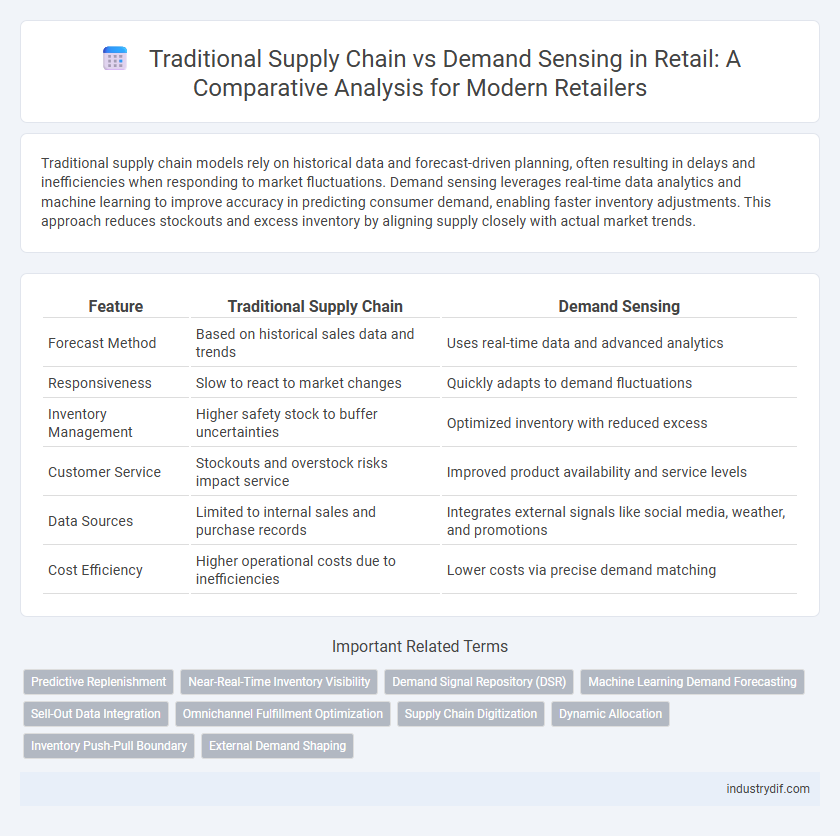

Traditional supply chain models rely on historical data and forecast-driven planning, often resulting in delays and inefficiencies when responding to market fluctuations. Demand sensing leverages real-time data analytics and machine learning to improve accuracy in predicting consumer demand, enabling faster inventory adjustments. This approach reduces stockouts and excess inventory by aligning supply closely with actual market trends.

Table of Comparison

| Feature | Traditional Supply Chain | Demand Sensing |

|---|---|---|

| Forecast Method | Based on historical sales data and trends | Uses real-time data and advanced analytics |

| Responsiveness | Slow to react to market changes | Quickly adapts to demand fluctuations |

| Inventory Management | Higher safety stock to buffer uncertainties | Optimized inventory with reduced excess |

| Customer Service | Stockouts and overstock risks impact service | Improved product availability and service levels |

| Data Sources | Limited to internal sales and purchase records | Integrates external signals like social media, weather, and promotions |

| Cost Efficiency | Higher operational costs due to inefficiencies | Lower costs via precise demand matching |

Introduction to Retail Supply Chain Dynamics

Retail supply chain dynamics have evolved from traditional forecast-driven models to demand sensing approaches that leverage real-time data for enhanced accuracy. Traditional supply chains depend on historical sales data to plan inventory and distribution, often leading to delays and stock imbalances. Demand sensing integrates advanced analytics and real-time market signals to respond faster to consumer demand fluctuations, optimizing inventory management and reducing operational costs.

Defining Traditional Supply Chain in Retail

The traditional supply chain in retail involves forecasting demand based on historical sales data and seasonal trends, often resulting in delayed responsiveness to market fluctuations. Inventory replenishment follows a fixed schedule, which can lead to overstock or stockouts due to inaccurate predictions. This linear approach emphasizes efficiency in production and distribution but lacks real-time adaptability to changing consumer preferences.

What is Demand Sensing in Retail?

Demand sensing in retail leverages real-time data and advanced analytics to forecast customer demand more accurately, improving inventory management and reducing stockouts or overstocks. Unlike traditional supply chain methods that rely on historical sales data and fixed ordering cycles, demand sensing adjusts forecasts based on current market conditions, promotions, and social trends. This approach enhances supply chain agility, enabling retailers to respond swiftly to fluctuating consumer behaviors and optimize operational efficiency.

Key Differences: Traditional Supply Chain vs Demand Sensing

Traditional supply chains rely heavily on historical sales data and fixed forecasting models, often resulting in delayed responses to market fluctuations. Demand sensing utilizes real-time data analytics, incorporating factors like current sales, weather, and social media trends to improve forecast accuracy and inventory management. This leads to faster decision-making, reduced stockouts, and enhanced customer satisfaction in retail environments.

Role of Data and Technology in Demand Sensing

Demand sensing leverages advanced data analytics, real-time point-of-sale data, and machine learning algorithms to improve demand forecasting accuracy in retail, contrasting with traditional supply chain models that rely on historical sales data and static forecasts. Technologies such as IoT sensors, AI-driven predictive analytics, and cloud computing enable retailers to detect subtle shifts in consumer behavior and market trends rapidly. This data-centric approach reduces inventory costs, minimizes stockouts, and enhances responsiveness to demand fluctuations.

Inventory Management: Traditional vs Demand Sensing Approaches

Traditional supply chain inventory management relies on historical sales data and fixed reorder points, often resulting in overstock or stockouts due to delayed demand visibility. Demand sensing utilizes real-time data and advanced analytics to predict short-term demand fluctuations, optimizing inventory levels and enhancing fulfillment rates. This approach reduces holding costs and improves responsiveness, aligning stock with actual consumer behavior more accurately than traditional methods.

Forecast Accuracy in Retail: A Comparative Analysis

Traditional supply chain forecasting in retail relies on historical sales data and fixed replenishment cycles, often resulting in lower forecast accuracy due to delayed response to market changes. Demand sensing integrates real-time data from POS systems, social media, and IoT devices, significantly enhancing forecast accuracy by capturing short-term demand fluctuations. Retailers implementing demand sensing report up to 20-30% improvement in forecast precision, leading to optimized inventory levels and reduced stockouts.

Impact on Customer Satisfaction and Service Levels

Traditional supply chains rely on historical sales data and fixed ordering schedules, often leading to stockouts or excess inventory that negatively impact customer satisfaction. Demand sensing leverages real-time data and advanced analytics to accurately forecast demand, resulting in improved service levels and higher customer satisfaction by ensuring product availability. Retailers adopting demand sensing can reduce lead times and respond swiftly to market changes, enhancing overall customer experience.

Challenges in Transitioning to Demand Sensing

Transitioning from traditional supply chain models to demand sensing presents challenges such as data integration complexities, requiring real-time analytics across diverse retail channels. Retailers face difficulties in aligning legacy systems with advanced demand sensing technologies to achieve accurate forecasting and inventory optimization. Overcoming organizational resistance and investing in skilled personnel are critical to successfully adopting demand sensing and enhancing supply chain responsiveness.

Future Trends: The Evolution of Retail Supply Chains

Future trends in retail supply chains emphasize a shift from traditional supply chain models to advanced demand sensing technologies that leverage real-time data and AI-driven analytics to improve forecasting accuracy. This evolution enables retailers to anticipate consumer demand fluctuations more effectively, reducing inventory costs and enhancing customer satisfaction. Integrating IoT devices and machine learning algorithms facilitates a more agile, responsive supply chain capable of adapting to dynamic market conditions and personalized shopping experiences.

Related Important Terms

Predictive Replenishment

Traditional supply chain methods rely on historical sales data and fixed reorder points, often leading to overstock or stockouts, while demand sensing leverages real-time analytics and AI-driven insights to enhance accuracy in inventory forecasting. Predictive replenishment within demand sensing optimizes stock levels by dynamically adjusting orders based on current market trends, consumer behavior, and external factors, increasing efficiency and customer satisfaction in retail operations.

Near-Real-Time Inventory Visibility

Traditional supply chain models rely on historical data and fixed reorder points, often resulting in delayed inventory replenishment and stockouts. Demand sensing leverages near-real-time inventory visibility through advanced analytics and IoT sensors, enabling retailers to respond rapidly to actual consumer demand and optimize stock levels dynamically.

Demand Signal Repository (DSR)

The Demand Signal Repository (DSR) centralizes real-time sales and inventory data, enabling retailers to enhance forecast accuracy and agility compared to traditional supply chains reliant on historical data and batch processing. Leveraging DSR technology helps optimize inventory levels, reduce stockouts, and improve responsiveness to changing consumer demand patterns.

Machine Learning Demand Forecasting

Machine learning demand forecasting enhances traditional supply chains by leveraging real-time data and advanced algorithms to predict consumer demand more accurately, reducing inventory costs and stockouts. Unlike conventional methods relying on historical sales and fixed schedules, demand sensing dynamically adjusts forecasts based on market trends, weather patterns, and social media signals for optimized retail operations.

Sell-Out Data Integration

Traditional supply chains rely heavily on historical sales forecasts and inventory data, often resulting in delayed responses to market shifts and stock imbalances. Integrating real-time sell-out data through demand sensing enhances accuracy in demand forecasting, enabling retailers to optimize inventory levels, reduce stockouts, and improve customer satisfaction by aligning supply closely with actual consumer purchases.

Omnichannel Fulfillment Optimization

Traditional supply chain models rely on fixed forecasting and centralized inventory, often leading to stockouts or overstock in omnichannel fulfillment scenarios. Demand sensing leverages real-time data analytics and AI to dynamically adjust inventory and distribution, significantly enhancing accuracy and reducing fulfillment times across multiple retail channels.

Supply Chain Digitization

Traditional supply chains rely on static forecasting models and batch processing, often causing delays and inefficiencies in inventory management. Demand sensing leverages real-time data analytics and IoT integration, driving supply chain digitization to enhance responsiveness and reduce stockouts in retail operations.

Dynamic Allocation

Traditional supply chains rely on fixed inventory forecasts and static allocation methods, often leading to overstock or stockouts as demand fluctuates. Demand sensing uses real-time data analytics and dynamic allocation algorithms to adjust inventory distribution efficiently across retail locations, enhancing responsiveness and reducing waste.

Inventory Push-Pull Boundary

The inventory push-pull boundary in traditional supply chains is typically fixed, leading to inventory being pushed based on forecasted demand, which often results in excess stock or stockouts. Demand sensing shifts this boundary closer to the customer, enabling real-time demand signals to pull inventory, thereby reducing lead times and improving inventory accuracy.

External Demand Shaping

Traditional supply chain models rely on historical sales data and fixed demand forecasts, limiting their ability to adapt to sudden market changes or promotional activities. Demand sensing leverages real-time external signals such as social media trends, weather patterns, and competitor promotions to dynamically shape demand and optimize inventory levels in retail.

Traditional Supply Chain vs Demand Sensing Infographic

industrydif.com

industrydif.com