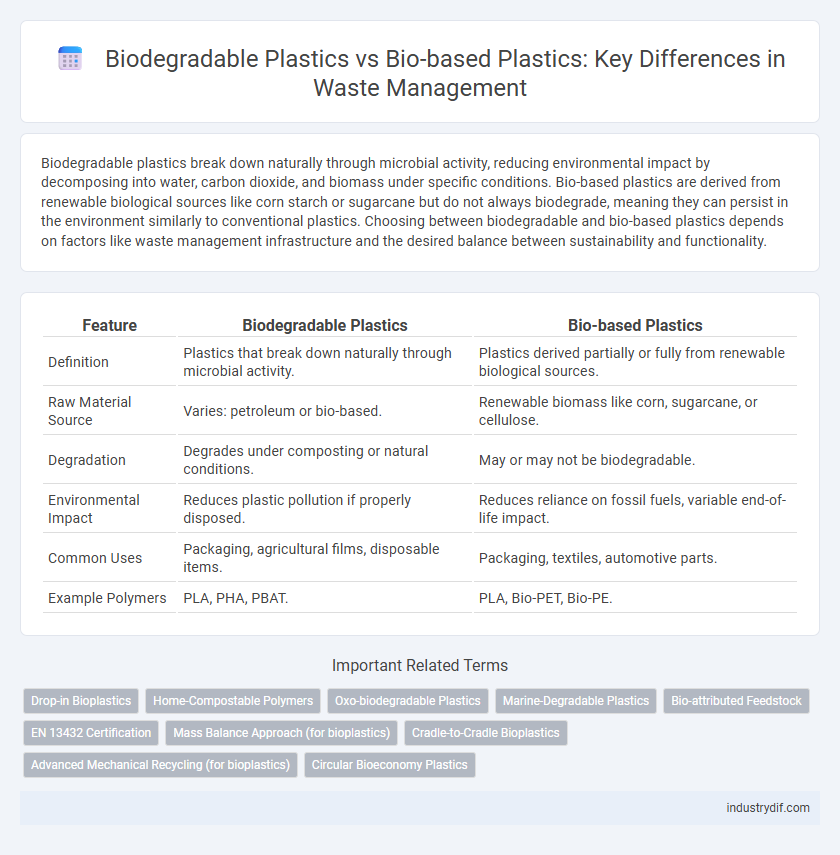

Biodegradable plastics break down naturally through microbial activity, reducing environmental impact by decomposing into water, carbon dioxide, and biomass under specific conditions. Bio-based plastics are derived from renewable biological sources like corn starch or sugarcane but do not always biodegrade, meaning they can persist in the environment similarly to conventional plastics. Choosing between biodegradable and bio-based plastics depends on factors like waste management infrastructure and the desired balance between sustainability and functionality.

Table of Comparison

| Feature | Biodegradable Plastics | Bio-based Plastics |

|---|---|---|

| Definition | Plastics that break down naturally through microbial activity. | Plastics derived partially or fully from renewable biological sources. |

| Raw Material Source | Varies: petroleum or bio-based. | Renewable biomass like corn, sugarcane, or cellulose. |

| Degradation | Degrades under composting or natural conditions. | May or may not be biodegradable. |

| Environmental Impact | Reduces plastic pollution if properly disposed. | Reduces reliance on fossil fuels, variable end-of-life impact. |

| Common Uses | Packaging, agricultural films, disposable items. | Packaging, textiles, automotive parts. |

| Example Polymers | PLA, PHA, PBAT. | PLA, Bio-PET, Bio-PE. |

Understanding Biodegradable Plastics

Biodegradable plastics break down naturally through microbial activity, converting into water, carbon dioxide, and biomass under specific environmental conditions, which helps reduce long-term pollution in ecosystems. These plastics are often made from renewable biological sources or petroleum-based materials designed for faster decomposition compared to conventional plastics. Understanding the specific degradation rates and environmental requirements is crucial for effective waste management and ensuring that biodegradable plastics contribute to sustainability goals.

Defining Bio-based Plastics

Bio-based plastics are derived from renewable biomass sources such as corn, sugarcane, or cellulose, distinguishing them from conventional plastics made from fossil fuels. These plastics can be either biodegradable or non-biodegradable, depending on their chemical structure and production process. Defining bio-based plastics involves understanding their origin from organic materials rather than petroleum, emphasizing sustainability through reduced carbon footprint and decreased reliance on non-renewable resources.

Key Differences Between Biodegradable and Bio-based Plastics

Biodegradable plastics break down into natural substances through microbial activity within a specific timeframe, reducing persistent waste in landfills. Bio-based plastics are derived from renewable biological materials like corn or sugarcane but do not always biodegrade, depending on their chemical structure. Understanding the distinction helps in selecting materials that align with environmental goals, balancing resource renewability and waste decomposition efficiency.

Environmental Impact Comparison

Biodegradable plastics break down through microbial activity, reducing long-term environmental pollution but often require specific composting conditions to decompose efficiently. Bio-based plastics, derived from renewable biomass such as corn or sugarcane, lower reliance on fossil fuels but do not always degrade quickly, potentially contributing to plastic waste accumulation. Comparing their environmental impact involves analyzing carbon footprint, degradation rate, and end-of-life management to determine sustainable waste reduction strategies.

Industrial Applications of Biodegradable Plastics

Biodegradable plastics are increasingly utilized in industrial applications such as packaging, agriculture, and waste management due to their ability to decompose under specific conditions, reducing environmental impact and landfill accumulation. These materials, often derived from renewable resources, offer functionality similar to conventional plastics while ensuring compliance with stringent eco-regulations in sectors like food service and horticulture. Their adoption supports circular economy models by enabling organic waste composting and mitigating plastic pollution in industrial waste streams.

Uses and Benefits of Bio-based Plastics

Bio-based plastics are derived from renewable sources like corn, sugarcane, or cellulose, making them a sustainable alternative to conventional plastics. Their primary uses include packaging, agriculture films, and disposable items, where reduced carbon footprint and biodegradability contribute significantly to environmental protection. Benefits of bio-based plastics include lower greenhouse gas emissions during production, reduced dependence on fossil fuels, and enhanced compatibility with existing recycling systems.

Decomposition and End-of-Life Processes

Biodegradable plastics break down naturally through microbial activity within months to years depending on environmental conditions, reducing landfill accumulation. Bio-based plastics, derived from renewable biomass, may not always be biodegradable and often require specific industrial composting facilities for effective decomposition. Proper end-of-life management, including composting or recycling infrastructure, is crucial to maximize environmental benefits and minimize waste impact.

Regulatory Standards and Certifications

Regulatory standards for biodegradable plastics often emphasize compostability criteria defined by organizations such as ASTM D6400 and EN 13432, ensuring these materials break down under specific environmental conditions. Bio-based plastics require certification to verify the percentage of renewable content, with standards like the USDA BioPreferred Program and the European Bio-based Content Certification providing quantifiable metrics. Compliance with these certifications aids manufacturers in meeting sustainability targets and enables clear labeling for consumers regarding environmental impact.

Market Trends in Sustainable Plastics

Biodegradable plastics are designed to break down naturally in specific environments, addressing waste management challenges by reducing long-term pollution, while bio-based plastics derive from renewable biomass sources such as cornstarch or sugarcane, promoting sustainability through reduced fossil fuel dependence. Market trends indicate a growing consumer preference for bio-based plastics due to their lower carbon footprint, with the global sustainable plastics market projected to reach USD 60 billion by 2030, driven by stringent environmental regulations and increasing corporate sustainability commitments. Innovation in recycling technologies and government incentives further accelerate adoption, positioning biodegradable and bio-based plastics as key components in the circular economy for waste reduction.

Future Prospects of Eco-friendly Plastic Alternatives

Biodegradable plastics, derived from materials that break down under natural conditions, offer promising waste reduction benefits but face challenges in scalability and composting infrastructure. Bio-based plastics, produced from renewable biological sources, aim to reduce carbon footprints yet vary widely in biodegradability and environmental impact. Advances in polymer science and waste management technologies are expected to enhance the sustainability and adoption of these eco-friendly plastic alternatives in the coming decade.

Related Important Terms

Drop-in Bioplastics

Drop-in bioplastics are bio-based plastics chemically identical to conventional plastics, allowing seamless integration into existing recycling and manufacturing systems without altering product performance. Unlike biodegradable plastics that degrade under specific conditions, drop-in bioplastics reduce carbon footprint while maintaining durability and compatibility with current infrastructure.

Home-Compostable Polymers

Home-compostable polymers are a subset of biodegradable plastics specifically designed to break down efficiently in household composting systems, unlike many bio-based plastics that may require industrial composting conditions. These materials, often derived from renewable resources like cornstarch or polylactic acid (PLA), help reduce plastic waste by decomposing into non-toxic substances within a typical home compost environment.

Oxo-biodegradable Plastics

Oxo-biodegradable plastics contain additives that trigger degradation through oxidation, breaking down into micro-fragments but often fail to biodegrade fully, causing environmental microplastic pollution. In contrast, bio-based plastics are derived from renewable biomass and can be designed for complete biodegradability under specific conditions, reducing long-term ecological impact.

Marine-Degradable Plastics

Marine-degradable plastics are engineered to break down in ocean environments through microbial activity, reducing long-term marine pollution compared to conventional biodegradable plastics that may not degrade efficiently in seawater. Bio-based plastics derived from renewable resources often lack the specific properties required for rapid marine degradation, making marine-degradable plastics a critical innovation for mitigating plastic waste impact on marine ecosystems.

Bio-attributed Feedstock

Bio-based plastics are derived from bio-attributed feedstocks such as corn, sugarcane, or cellulose, which reduce dependency on fossil fuels and lower carbon footprints in plastic production. Unlike biodegradable plastics that primarily focus on end-of-life decomposition, bio-based plastics emphasize sustainable sourcing of raw materials, contributing to a circular economy in waste management.

EN 13432 Certification

EN 13432 certification defines stringent criteria for biodegradable plastics, ensuring at least 90% disintegration within 12 weeks and complete biodegradation within six months under industrial composting conditions. Bio-based plastics, derived from renewable biomass, may not inherently meet EN 13432 standards unless they demonstrate certified compostability and biodegradability according to these requirements.

Mass Balance Approach (for bioplastics)

The Mass Balance Approach enables the integration of renewable biomass into conventional plastic production processes by tracking the proportion of bio-based feedstock in the final product, enhancing sustainability credentials of both biodegradable plastics and bio-based plastics. This method supports transparency and traceability in production, ensuring that the environmental benefits of bio-based content are quantified without the need for entirely separate manufacturing lines.

Cradle-to-Cradle Bioplastics

Cradle-to-cradle bioplastics emphasize sustainable production and end-of-life recyclability, contrasting biodegradable plastics which primarily focus on decomposition under specific conditions, while bio-based plastics are derived from renewable biomass but may not be inherently biodegradable. The cradle-to-cradle approach integrates closed-loop systems, ensuring bioplastics contribute to circular economy goals by minimizing waste and environmental impact throughout their lifecycle.

Advanced Mechanical Recycling (for bioplastics)

Advanced mechanical recycling techniques for bioplastics enhance the recovery of biodegradable and bio-based plastics by preserving polymer integrity and reducing contamination rates, thus improving the circularity of these materials. These innovations enable effective sorting and reprocessing of bioplastics, minimizing environmental impact and promoting sustainable waste management within the bioplastic sector.

Circular Bioeconomy Plastics

Biodegradable plastics break down naturally through microbial activity, reducing landfill impact, while bio-based plastics derive from renewable biomass, supporting sustainable resource cycles. Circular bioeconomy plastics integrate these attributes by promoting closed-loop systems that optimize material recovery and minimize environmental footprint.

Biodegradable Plastics vs Bio-based Plastics Infographic

industrydif.com

industrydif.com