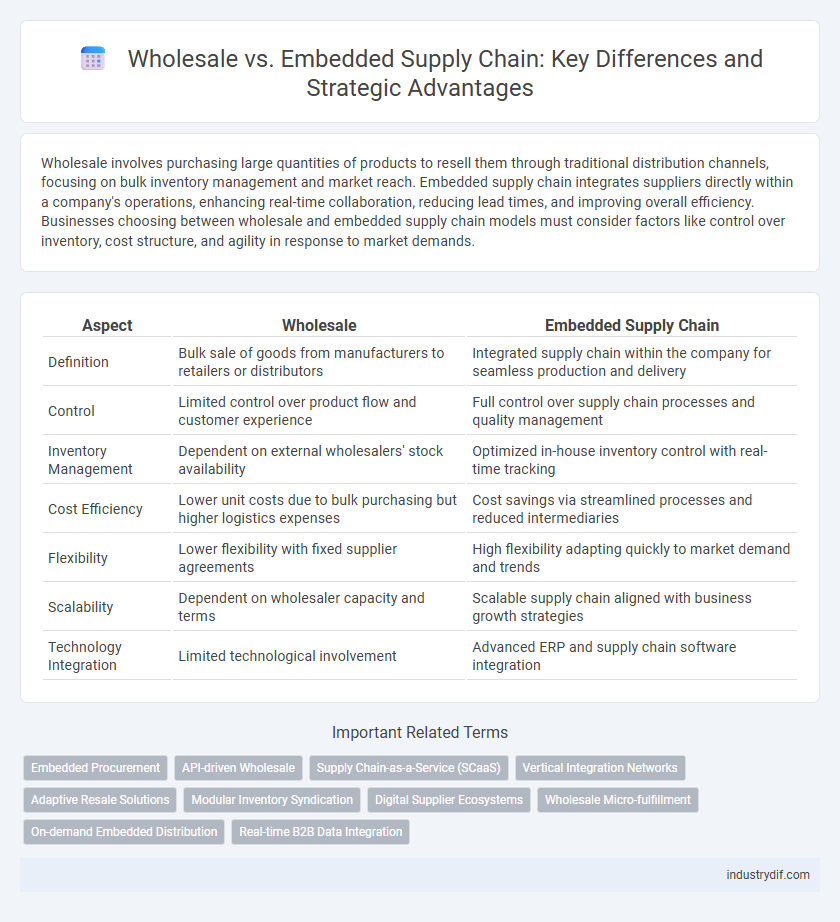

Wholesale involves purchasing large quantities of products to resell them through traditional distribution channels, focusing on bulk inventory management and market reach. Embedded supply chain integrates suppliers directly within a company's operations, enhancing real-time collaboration, reducing lead times, and improving overall efficiency. Businesses choosing between wholesale and embedded supply chain models must consider factors like control over inventory, cost structure, and agility in response to market demands.

Table of Comparison

| Aspect | Wholesale | Embedded Supply Chain |

|---|---|---|

| Definition | Bulk sale of goods from manufacturers to retailers or distributors | Integrated supply chain within the company for seamless production and delivery |

| Control | Limited control over product flow and customer experience | Full control over supply chain processes and quality management |

| Inventory Management | Dependent on external wholesalers' stock availability | Optimized in-house inventory control with real-time tracking |

| Cost Efficiency | Lower unit costs due to bulk purchasing but higher logistics expenses | Cost savings via streamlined processes and reduced intermediaries |

| Flexibility | Lower flexibility with fixed supplier agreements | High flexibility adapting quickly to market demand and trends |

| Scalability | Dependent on wholesaler capacity and terms | Scalable supply chain aligned with business growth strategies |

| Technology Integration | Limited technological involvement | Advanced ERP and supply chain software integration |

Defining Wholesale and Embedded Supply Chain

Wholesale involves purchasing goods in large quantities directly from manufacturers to sell them at a markup to retailers or consumers, emphasizing bulk transactions and inventory management. An embedded supply chain integrates supply chain functions within the organizational processes, allowing seamless coordination between production, procurement, and distribution to optimize efficiency and reduce costs. The key difference lies in wholesale prioritizing volume sales and external distribution, while embedded supply chains focus on internal coordination and operational integration.

Key Differences Between Wholesale and Embedded Supply Chain

Wholesale involves purchasing goods in large quantities from manufacturers to resell at a profit, focusing mainly on distribution and inventory management. Embedded supply chain integrates supply chain functions directly within manufacturers or retailers, optimizing processes such as production, logistics, and sales in a seamless system. Key differences include the level of integration, with wholesale operating as an intermediary and embedded supply chains emphasizing internal coordination and real-time data sharing.

Benefits of Wholesale Supply Chains

Wholesale supply chains offer significant benefits such as economies of scale, streamlined inventory management, and reduced operational costs through bulk purchasing power. They enable faster distribution and improved market reach by consolidating products from multiple manufacturers to various retailers efficiently. Enhanced supply chain visibility and risk mitigation are also achieved through centralized coordination and standardized processes.

Advantages of Embedded Supply Chains

Embedded supply chains enhance operational efficiency by integrating suppliers directly into the production process, reducing lead times and minimizing inventory costs. This close collaboration improves product quality and enables real-time data sharing, facilitating better demand forecasting and rapid response to market changes. By streamlining logistics and fostering supplier relationships, embedded supply chains offer greater flexibility and scalability compared to traditional wholesale models.

Impact on Inventory Management

Wholesale inventory management centralizes stock across fewer locations, enabling bulk purchasing and streamlined distribution but often requiring larger storage capacity and higher holding costs. Embedded supply chain models integrate inventory closer to the end customer, reducing lead times and enhancing responsiveness while shifting focus to real-time demand forecasting and minimizing overstock risks. Optimizing inventory levels in embedded supply chains leverages advanced analytics and IoT technology to synchronize supply with dynamic consumer demand patterns.

Scalability in Wholesale vs Embedded Models

Wholesale models offer greater scalability by enabling businesses to purchase and distribute large volumes of products across multiple channels without the need for extensive integration or customization. Embedded supply chain models, while providing tighter control and seamless product integration, often face scalability constraints due to higher complexity and dependency on specific platform compatibility. Scalability in wholesale systems is driven by standardized processes and broad supplier networks, whereas embedded models require tailored solutions that limit rapid expansion.

Cost Structure Comparison

Wholesale models typically incur higher upfront inventory costs and storage expenses due to bulk purchasing and warehousing requirements. Embedded supply chains reduce costs by integrating production and distribution, minimizing intermediaries, and streamlining logistics. Cost structures in embedded supply chains benefit from lower handling fees and improved operational efficiencies, leading to enhanced margin control.

Integration with Technology Platforms

Wholesale operations benefit from seamless integration with advanced technology platforms, enabling real-time inventory management, automated order processing, and enhanced demand forecasting. Embedded supply chains leverage these integrations more deeply by connecting multiple partners through shared digital ecosystems, improving transparency and collaboration across the entire supply network. This technology-driven integration reduces operational costs, accelerates delivery times, and enhances scalability for wholesale businesses.

Industry Use Cases: Wholesale vs Embedded

Wholesale models excel in industries requiring bulk distribution, such as consumer electronics and fashion apparel, by leveraging established networks and volume discounts to optimize cost-efficiency. Embedded supply chains integrate directly within manufacturing or retail processes, prevalent in automotive and electronics industries, enhancing real-time inventory management and reducing lead times. The choice between wholesale and embedded supply chains depends on factors like product complexity, demand variability, and the need for supply chain transparency in specific industry use cases.

Choosing the Right Model for Your Business

Selecting the ideal supply chain model depends on your business size, product type, and control requirements; wholesale offers broad market reach with lower operational complexity, while embedded supply chains provide closer integration and customization. Businesses dealing in high-volume standardized goods often benefit from wholesale due to streamlined distribution and inventory management. Conversely, companies prioritizing quality control and brand consistency may find embedded supply chains more advantageous for maintaining direct oversight over production and delivery processes.

Related Important Terms

Embedded Procurement

Embedded procurement streamlines supply chain operations by integrating purchasing directly into business processes, reducing lead times and enhancing cost efficiency compared to traditional wholesale models. This approach leverages real-time data and supplier collaboration, enabling agile sourcing and improved inventory management within an embedded supply chain framework.

API-driven Wholesale

API-driven wholesale transforms traditional supply chains by enabling real-time inventory management and seamless integration between suppliers and retailers, reducing lead times and operational costs. This contrasts with embedded supply chains, where supply processes are tightly integrated within a single company, limiting flexibility and scalability across diverse wholesale partners.

Supply Chain-as-a-Service (SCaaS)

Wholesale relies on bulk purchasing and traditional distribution channels, while Embedded Supply Chain integrates supply chain functions directly into retail or production processes, offering seamless real-time inventory and logistics management. Supply Chain-as-a-Service (SCaaS) enhances efficiency by providing scalable, cloud-based solutions that optimize procurement, warehousing, and delivery operations without the need for extensive in-house infrastructure.

Vertical Integration Networks

Vertical integration networks in wholesale streamline product flow by consolidating supply chain stages under one organization, reducing reliance on external suppliers and enhancing cost control. Embedded supply chains rely on external partnerships, creating a complex web of interactions that can limit responsiveness and increase transaction costs compared to the coordinated, vertically integrated wholesale systems.

Adaptive Resale Solutions

Adaptive resale solutions in wholesale enable dynamic inventory management and real-time pricing adjustments, enhancing responsiveness to market fluctuations compared to embedded supply chain models. These solutions leverage data analytics and flexible distribution networks to optimize product availability and reduce lead times, driving operational efficiency and customer satisfaction.

Modular Inventory Syndication

Wholesale models leverage Modular Inventory Syndication to streamline bulk product distribution by integrating diverse supplier inventories into a unified platform. Embedded Supply Chain systems embed inventory data directly within retail ecosystems, enhancing real-time visibility but often lacking the scalability and flexibility offered by modular syndication in wholesale operations.

Digital Supplier Ecosystems

Digital supplier ecosystems transform traditional wholesale by integrating embedded supply chain processes, enabling real-time data exchange, enhanced transparency, and streamlined operations. This approach leverages cloud-based platforms and advanced analytics to optimize inventory management, reduce lead times, and improve supplier collaboration across global networks.

Wholesale Micro-fulfillment

Wholesale micro-fulfillment centers optimize inventory management by enabling rapid order processing and reducing last-mile delivery costs compared to traditional embedded supply chain models. These centers leverage automation and localized storage to enhance scalability and meet increasing demand for faster, cost-efficient wholesale distribution.

On-demand Embedded Distribution

On-demand embedded distribution in wholesale streamlines inventory management by integrating supply chain processes directly into various sales platforms, enabling real-time product availability and rapid fulfillment. This approach reduces overhead costs and enhances customer responsiveness compared to traditional wholesale models that rely on bulk purchasing and separate distribution channels.

Real-time B2B Data Integration

Wholesale leverages real-time B2B data integration to synchronize inventory, pricing, and order processing across multiple suppliers and retailers, enhancing supply chain visibility and operational efficiency. Embedded supply chains integrate these data streams directly into enterprise resource planning (ERP) systems, enabling automated decision-making and reducing latency in demand forecasting and fulfillment.

Wholesale vs Embedded Supply Chain Infographic

industrydif.com

industrydif.com