Manual harvesting allows for selective picking and careful handling of delicate crops, ensuring higher quality produce but requiring significant labor and time. Autonomous harvesting systems increase efficiency and reduce labor costs by using advanced robotics and AI to perform repetitive tasks quickly and consistently. Balancing the precision of manual methods with the speed of automation can enhance overall farm productivity and sustainability.

Table of Comparison

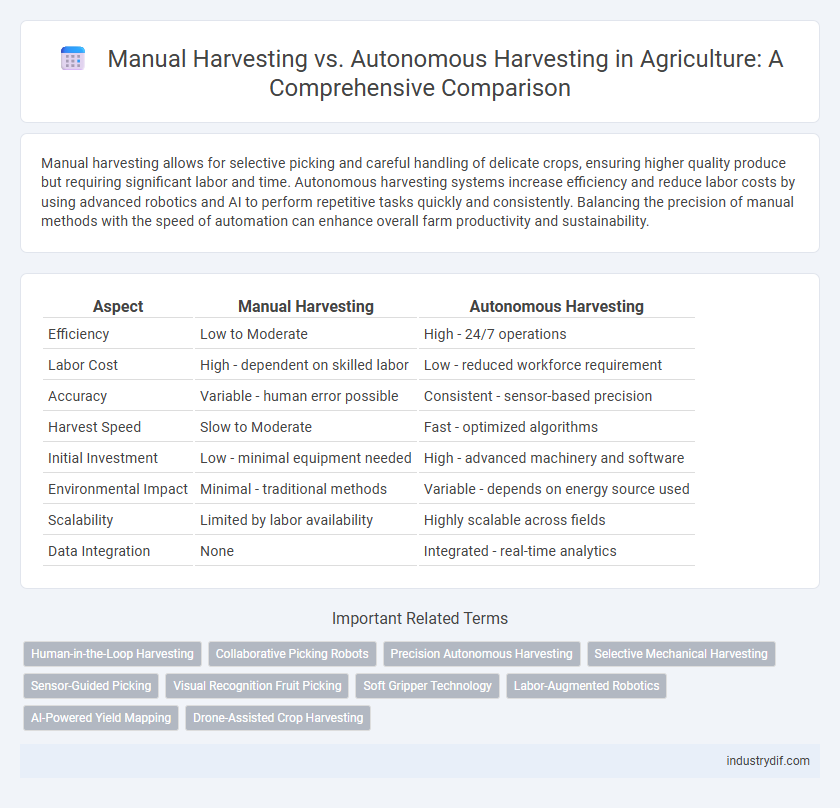

| Aspect | Manual Harvesting | Autonomous Harvesting |

|---|---|---|

| Efficiency | Low to Moderate | High - 24/7 operations |

| Labor Cost | High - dependent on skilled labor | Low - reduced workforce requirement |

| Accuracy | Variable - human error possible | Consistent - sensor-based precision |

| Harvest Speed | Slow to Moderate | Fast - optimized algorithms |

| Initial Investment | Low - minimal equipment needed | High - advanced machinery and software |

| Environmental Impact | Minimal - traditional methods | Variable - depends on energy source used |

| Scalability | Limited by labor availability | Highly scalable across fields |

| Data Integration | None | Integrated - real-time analytics |

Introduction to Manual and Autonomous Harvesting

Manual harvesting involves human laborers physically picking crops, which allows for precise selection and minimal crop damage but is limited by labor availability and higher operational costs. Autonomous harvesting utilizes robotic systems and AI technology to efficiently gather crops with consistent speed and reduced labor dependence, improving scalability for large farms. Advances in machine vision and sensor integration enhance autonomous systems' ability to identify ripeness and navigate complex field conditions, positioning them as a sustainable solution for future agriculture.

Evolution of Harvesting Methods in Agriculture

Manual harvesting, traditionally reliant on human labor for crop collection, remains prevalent in regions with limited mechanization but faces challenges such as labor shortages and inefficiency. Autonomous harvesting employs advanced technologies like AI-powered robots, GPS guidance, and machine vision to increase precision, speed, and reduce operational costs. The evolution from manual to autonomous harvesting reflects significant advancements in agricultural engineering, enhancing productivity and sustainability in modern farming practices.

Key Technologies Enabling Autonomous Harvesting

Autonomous harvesting relies on advanced technologies such as computer vision, artificial intelligence, and robotics to precisely identify and pick crops, significantly improving efficiency compared to manual harvesting. Machine learning algorithms enable real-time decision-making for optimal fruit selection and minimal damage, while GPS and LiDAR systems ensure accurate navigation and operation within diverse field conditions. Integration of sensor networks and IoT devices allows for continuous monitoring of crop maturity and environmental factors, enhancing the overall productivity and sustainability of autonomous harvesting systems.

Labor Requirements: Manual vs Autonomous Approaches

Manual harvesting demands intensive labor input, often requiring large seasonal workforces to manage fruit picking, sorting, and transportation. Autonomous harvesting leverages advanced robotics and AI technologies to reduce dependency on human labor, enhancing efficiency and consistency while operating across extended hours. The shift toward autonomous methods addresses labor shortages and high labor costs, making agricultural production more scalable and cost-effective.

Efficiency and Productivity Comparison

Manual harvesting relies heavily on human labor, resulting in slower crop collection and higher labor costs, especially for large-scale farms. Autonomous harvesting uses advanced robotics and AI technology to operate continuously with consistent precision, significantly increasing throughput and reducing operational downtime. Studies show autonomous systems can boost productivity by up to 40% compared to manual methods, optimizing harvest timing and minimizing crop damage.

Cost Analysis of Manual and Autonomous Harvesting

Manual harvesting incurs higher labor costs due to intensive human involvement and seasonal workforce demand, often leading to increased operational expenses. Autonomous harvesting systems require significant upfront investment in machinery and technology but reduce long-term labor costs and improve efficiency, resulting in lower cost per unit over time. Evaluating cost-effectiveness depends on farm size, crop type, and technology adoption rate, with autonomous solutions showing greater advantages in large-scale operations.

Crop Quality and Yield Considerations

Manual harvesting allows for careful selection and handling of crops, which can preserve quality but often results in slower processing and potential yield loss due to labor fatigue and inconsistency. Autonomous harvesting technologies offer higher efficiency and uniformity, enhancing yield by reducing crop damage and enabling timely harvests, though initial costs and machine calibration are crucial for optimal crop quality. Balancing investment in robotics with crop-specific requirements is essential to maximizing both quality and yield in modern agriculture.

Environmental Impact and Sustainability

Manual harvesting reduces fuel emissions since it relies primarily on human labor, lowering the carbon footprint compared to machinery. Autonomous harvesting uses advanced robotics powered by electricity, which can be sourced from renewables, potentially minimizing soil compaction and reducing pesticide use through precision agriculture. Both methods impact biodiversity differently; manual harvesting tends to have less disruption, while autonomous systems optimize resource efficiency for sustainable crop production.

Safety Challenges in Harvesting Methods

Manual harvesting poses significant safety challenges including risks of musculoskeletal injuries, exposure to hazardous chemicals, and accidents related to repetitive tasks or heavy machinery. Autonomous harvesting systems reduce direct human involvement, minimizing physical injury risks but introduce new safety concerns such as malfunctioning robots, sensor failures, and the need for strict operational protocols to prevent accidents. Effective integration of safety measures in both manual and autonomous harvesting is crucial to protect workers and ensure efficient agricultural productivity.

Future Trends in Agricultural Harvesting Technologies

Future trends in agricultural harvesting technologies emphasize increased adoption of autonomous harvesting systems equipped with AI-driven sensors and machine learning algorithms to enhance precision and efficiency. Manual harvesting, while still prevalent in small-scale and specialty crop production, faces gradual decline due to labor shortages and rising operational costs. Integration of autonomous robots with IoT and advanced data analytics will revolutionize crop yield optimization and reduce post-harvest losses.

Related Important Terms

Human-in-the-Loop Harvesting

Human-in-the-loop harvesting combines manual labor with autonomous machinery, enhancing crop yield accuracy and efficiency by leveraging real-time human decision-making alongside automated processes. This hybrid approach minimizes errors common in fully autonomous systems while reducing worker fatigue and operational costs typical in manual harvesting.

Collaborative Picking Robots

Collaborative picking robots in agriculture enhance manual harvesting efficiency by working alongside human labor to increase picking speed and accuracy while reducing fatigue. These autonomous systems use advanced sensors and AI to identify ripe crops, enabling seamless integration that improves yield quality and operational cost-effectiveness.

Precision Autonomous Harvesting

Precision autonomous harvesting employs advanced sensors, machine learning algorithms, and GPS technology to optimize crop yield and reduce waste compared to manual harvesting, which relies heavily on human labor and is prone to inconsistency. This technology enables selective picking with exact timing, improving crop quality and operational efficiency across diverse agricultural environments.

Selective Mechanical Harvesting

Selective mechanical harvesting enhances crop yield quality by precisely targeting ripe produce, reducing damage and waste compared to manual harvesting. Advanced sensors and AI-driven machinery improve sorting accuracy and efficiency, making autonomous selective harvesting a cost-effective alternative for high-value crops like vineyards and orchards.

Sensor-Guided Picking

Sensor-guided picking in autonomous harvesting leverages advanced machine vision and LIDAR technology to identify and selectively harvest ripe crops, significantly enhancing efficiency compared to traditional manual harvesting methods. This technology reduces human labor dependency, minimizes crop damage, and increases yield accuracy by precisely targeting produce at optimal maturity stages.

Visual Recognition Fruit Picking

Manual harvesting relies heavily on human visual recognition to identify ripe fruits, which can be time-consuming and prone to errors under varying environmental conditions. Autonomous harvesting systems utilize advanced visual recognition technologies, such as machine learning and computer vision, to accurately detect and pick fruits, improving efficiency and reducing labor costs.

Soft Gripper Technology

Soft gripper technology enhances manual harvesting by providing delicate handling of fruits and vegetables, reducing damage and optimizing yield quality. Autonomous harvesting systems equipped with advanced soft grippers increase efficiency and precision in picking crops, minimizing labor costs and improving post-harvest product integrity.

Labor-Augmented Robotics

Labor-augmented robotics in agriculture combines manual harvesting techniques with autonomous systems to enhance productivity and precision. These hybrid models leverage human oversight to optimize robotic efficiency, reduce labor costs, and improve crop handling quality compared to fully manual or fully autonomous harvesting.

AI-Powered Yield Mapping

AI-powered yield mapping enhances autonomous harvesting by providing precise, real-time data on crop health and productivity, enabling targeted harvesting and reducing waste. Manual harvesting lacks this advanced data integration, resulting in less efficient yield prediction and increased labor costs.

Drone-Assisted Crop Harvesting

Drone-assisted crop harvesting combines precision technology with traditional manual labor, enabling targeted harvesting that reduces crop damage and increases efficiency. This method leverages drones equipped with advanced sensors and AI algorithms to identify ripe crops, streamline collection processes, and optimize yield management on large agricultural fields.

Manual Harvesting vs Autonomous Harvesting Infographic

industrydif.com

industrydif.com