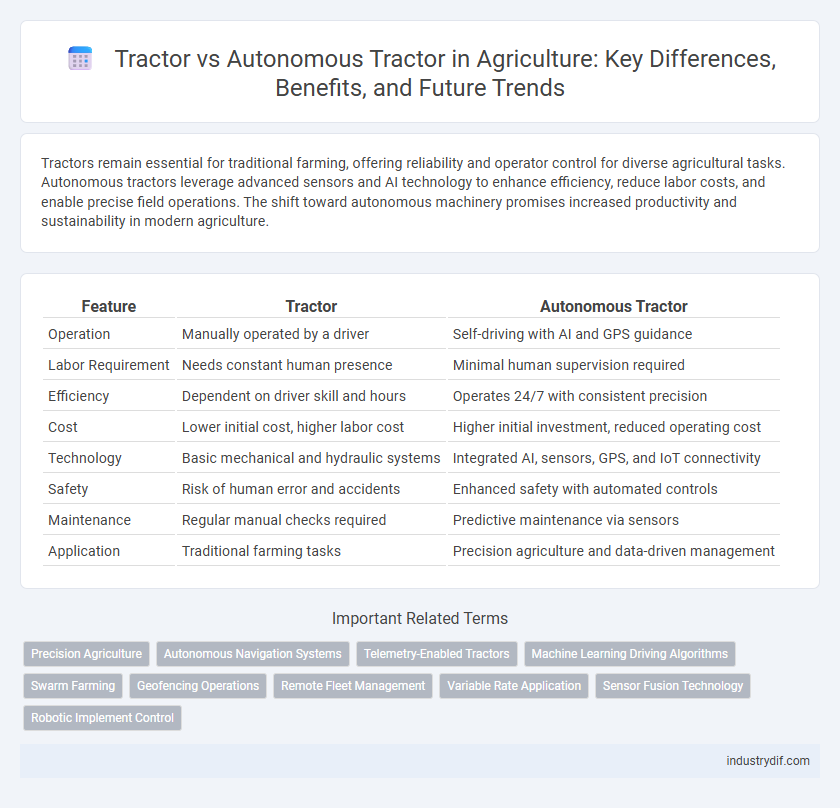

Tractors remain essential for traditional farming, offering reliability and operator control for diverse agricultural tasks. Autonomous tractors leverage advanced sensors and AI technology to enhance efficiency, reduce labor costs, and enable precise field operations. The shift toward autonomous machinery promises increased productivity and sustainability in modern agriculture.

Table of Comparison

| Feature | Tractor | Autonomous Tractor |

|---|---|---|

| Operation | Manually operated by a driver | Self-driving with AI and GPS guidance |

| Labor Requirement | Needs constant human presence | Minimal human supervision required |

| Efficiency | Dependent on driver skill and hours | Operates 24/7 with consistent precision |

| Cost | Lower initial cost, higher labor cost | Higher initial investment, reduced operating cost |

| Technology | Basic mechanical and hydraulic systems | Integrated AI, sensors, GPS, and IoT connectivity |

| Safety | Risk of human error and accidents | Enhanced safety with automated controls |

| Maintenance | Regular manual checks required | Predictive maintenance via sensors |

| Application | Traditional farming tasks | Precision agriculture and data-driven management |

Introduction to Traditional and Autonomous Tractors

Traditional tractors, powered by internal combustion engines and manually operated by drivers, have long been essential for plowing, planting, and harvesting in agriculture. Autonomous tractors utilize advanced GPS, sensors, and AI technology to perform these tasks without human intervention, increasing efficiency and precision on farms. The integration of autonomous systems reduces labor costs and minimizes human error while enabling continuous operation under optimal conditions.

Key Differences Between Conventional and Autonomous Tractors

Conventional tractors require manual operation involving steering, gear shifting, and speed control, whereas autonomous tractors utilize GPS technology, sensors, and advanced algorithms to perform tasks with minimal human intervention. Autonomous tractors enhance precision farming by optimizing fuel efficiency, reducing soil compaction, and enabling 24/7 operation, which conventional tractors cannot achieve. Maintenance for autonomous tractors often involves sophisticated software updates and sensor calibration, differing significantly from the primarily mechanical upkeep needed for conventional models.

Technology Behind Autonomous Tractors

Autonomous tractors utilize advanced technologies such as GPS-based precision guidance, AI-powered sensors, and machine learning algorithms to perform farming tasks without human intervention. These smart machines integrate real-time data analytics and IoT connectivity to optimize field operations, improve accuracy, and reduce fuel consumption. In contrast, traditional tractors rely on manual operation and lack the adaptive capabilities inherent in autonomous systems.

Operational Efficiency: Manual vs Autonomous

Manual tractors require constant human supervision, which limits operational hours and increases labor costs, while autonomous tractors operate continuously with precise GPS-guided systems, enhancing field coverage and reducing downtime. Autonomous tractors leverage advanced sensors and AI to optimize fuel consumption and implement real-time adjustments, translating to higher crop yields and lower input costs. This technological shift in operational efficiency enables scalable farming operations with consistent performance regardless of operator skill or fatigue.

Cost Analysis: Initial Investment and Long-term Savings

Tractors require a lower initial investment, typically ranging from $25,000 to $50,000, whereas autonomous tractors can cost between $100,000 and $250,000, reflecting advanced sensor and AI technology. Long-term savings of autonomous tractors include reduced labor costs, increased precision in planting and harvesting, and lower fuel consumption, potentially offsetting the high upfront expense within five to seven years. Cost analysis shows autonomous tractors improve operational efficiency and reduce ongoing expenses despite a significantly higher initial investment compared to conventional tractors.

Labor Requirements and Workforce Impacts

Traditional tractors require skilled operators to manage complex controls, resulting in high labor demands and increased workforce needs during peak farming seasons. Autonomous tractors leverage GPS, AI, and sensor technologies to perform tasks with minimal human intervention, significantly reducing labor requirements and enabling farmers to reallocate workforce resources. The shift towards autonomous machinery could lead to a decreased demand for manual labor while increasing the need for technical skills in machinery maintenance and oversight.

Safety Features and Risk Management

Tractors equipped with advanced safety features such as rollover protection systems (ROPS) and seat belts reduce operator injury risks during traditional farming operations. Autonomous tractors incorporate sensor-based obstacle detection, GPS navigation, and real-time machine monitoring to minimize human error and enhance overall field safety. Implementing autonomous technology supports comprehensive risk management by reducing operator fatigue and enabling remote operation, thereby lowering the likelihood of accidents and improving farm safety standards.

Environmental Impact and Sustainability

Traditional tractors emit significant greenhouse gases due to fossil fuel combustion, contributing to air pollution and soil compaction. Autonomous tractors, often powered by electric or hybrid systems, reduce carbon emissions and optimize fuel efficiency through precise navigation and operation. This innovation promotes sustainable agriculture by minimizing environmental impact and enhancing resource use efficiency.

Adoption Challenges and Industry Barriers

Farmers face significant adoption challenges when integrating autonomous tractors due to high initial costs, complex technology requirements, and concerns over reliability in varied field conditions. Traditional tractors remain dominant as industry barriers such as limited infrastructure for autonomous operations and a lack of technical support slow the shift towards automation. Regulatory uncertainties and resistance to change among small-scale farmers further impede widespread acceptance of autonomous tractor technology.

Future Trends in Tractor Automation

Future trends in tractor automation emphasize the integration of AI and machine learning to enhance precision farming and operational efficiency. Autonomous tractors equipped with advanced sensors and GPS technology enable real-time data collection and adaptive navigation, reducing labor costs and minimizing environmental impact. Increased adoption of robotics and IoT connectivity in agricultural machinery promises to revolutionize crop management and optimize resource usage for sustainable farming practices.

Related Important Terms

Precision Agriculture

Tractors equipped with GPS and sensor technologies enable traditional precision agriculture by enhancing field mapping and variable rate applications, while autonomous tractors leverage advanced AI and machine learning to execute these tasks with higher accuracy and efficiency, reducing human error and labor costs. The integration of real-time data analytics in autonomous tractors further optimizes crop yield and resource management by continuously adapting operations based on soil and crop conditions.

Autonomous Navigation Systems

Autonomous tractors utilize advanced navigation systems such as GPS-guided steering, LiDAR sensors, and real-time data processing to enhance precision farming and reduce human error. These systems enable consistent field operations, optimize resource use, and increase productivity compared to traditional manually operated tractors.

Telemetry-Enabled Tractors

Telemetry-enabled tractors collect real-time data on equipment performance, soil conditions, and crop health, enabling precise farming decisions and minimizing downtime through predictive maintenance. Autonomous tractors leverage this telemetry data to operate with minimal human intervention, increasing efficiency and consistency in field operations.

Machine Learning Driving Algorithms

Machine learning driving algorithms in autonomous tractors enable precise navigation and adaptive decision-making by analyzing real-time environmental data, significantly improving efficiency over traditional tractors. These algorithms optimize fuel consumption, reduce operator fatigue, and enhance crop yield through continuous learning and adjustment to varying field conditions.

Swarm Farming

Swarm farming leverages autonomous tractors equipped with advanced sensors and AI to coordinate multiple units for efficient, large-scale field operations, significantly increasing precision and reducing labor costs compared to traditional single-operator tractors. This technology enables real-time data sharing and adaptive task allocation among autonomous units, optimizing planting, harvesting, and soil management while minimizing fuel consumption and environmental impact.

Geofencing Operations

Tractors equipped with geofencing technology enable precise boundary control to prevent operations outside designated agricultural zones, reducing crop damage and soil compaction. Autonomous tractors utilize advanced GPS-enabled geofencing systems combined with real-time data analytics, enhancing operational efficiency and safety by automatically stopping or adjusting tasks when boundaries are approached.

Remote Fleet Management

Remote fleet management enhances efficiency by allowing farmers to monitor and control both traditional tractors and autonomous tractors through centralized software platforms, optimizing operations and reducing downtime. Autonomous tractors equipped with IoT sensors and GPS enable real-time data collection and remote adjustments, surpassing manual capabilities of conventional tractors in precision agriculture.

Variable Rate Application

Variable Rate Application (VRA) enhances precision farming by allowing tractors to adjust input levels such as fertilizers and pesticides based on real-time field data, optimizing resource use and crop yield. Autonomous tractors equipped with advanced sensors and GPS technology improve VRA efficiency by enabling continuous, accurate, and automated adjustments without human intervention.

Sensor Fusion Technology

Tractor sensor fusion technology integrates data from GPS, LiDAR, cameras, and inertial measurement units, enhancing precision in navigation and field operations compared to traditional tractors. Autonomous tractors leverage this sensor fusion to execute complex tasks such as obstacle detection, terrain mapping, and adaptive steering, significantly increasing efficiency and reducing human labor in agricultural management.

Robotic Implement Control

Robotic implement control in autonomous tractors enables precise, automated adjustment of farming equipment for optimal soil engagement, seed placement, and input application, significantly improving efficiency compared to traditional tractors. This technology reduces human error and labor costs while enhancing crop yields through real-time sensor feedback and machine learning algorithms.

Tractor vs Autonomous Tractor Infographic

industrydif.com

industrydif.com