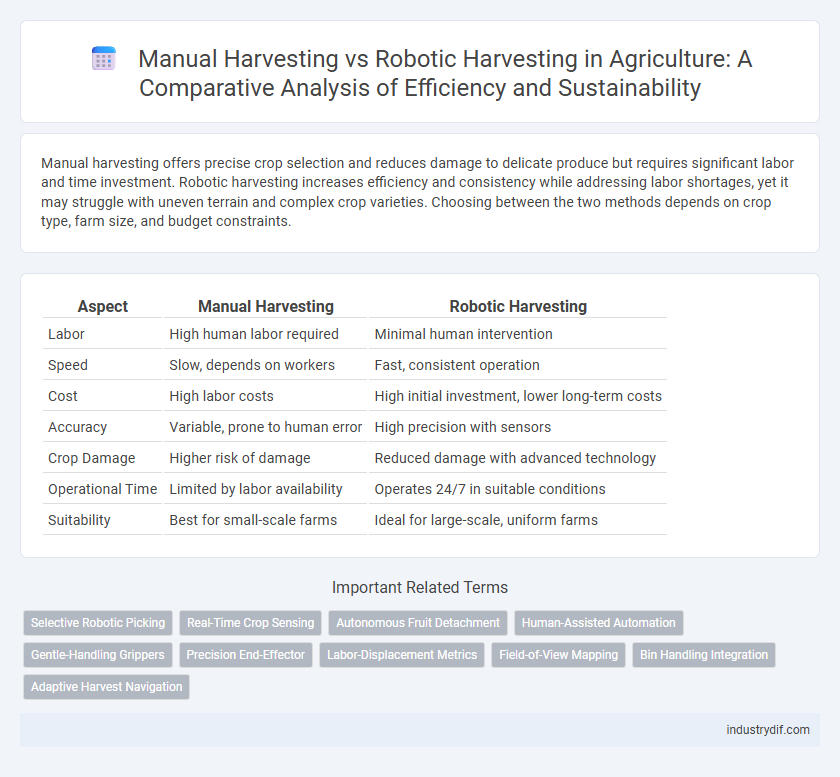

Manual harvesting offers precise crop selection and reduces damage to delicate produce but requires significant labor and time investment. Robotic harvesting increases efficiency and consistency while addressing labor shortages, yet it may struggle with uneven terrain and complex crop varieties. Choosing between the two methods depends on crop type, farm size, and budget constraints.

Table of Comparison

| Aspect | Manual Harvesting | Robotic Harvesting |

|---|---|---|

| Labor | High human labor required | Minimal human intervention |

| Speed | Slow, depends on workers | Fast, consistent operation |

| Cost | High labor costs | High initial investment, lower long-term costs |

| Accuracy | Variable, prone to human error | High precision with sensors |

| Crop Damage | Higher risk of damage | Reduced damage with advanced technology |

| Operational Time | Limited by labor availability | Operates 24/7 in suitable conditions |

| Suitability | Best for small-scale farms | Ideal for large-scale, uniform farms |

Introduction to Manual and Robotic Harvesting

Manual harvesting involves human laborers picking crops by hand, offering precision and adaptability for delicate or irregularly shaped produce but often resulting in slower processing and higher labor costs. Robotic harvesting employs automated machinery equipped with sensors and AI to identify, pick, and collect crops, significantly increasing speed and efficiency while reducing labor dependency. Advances in computer vision and machine learning enhance robotic systems' ability to handle diverse crop types, aiming to optimize yield and reduce post-harvest losses.

Key Differences Between Manual and Robotic Harvesting

Manual harvesting relies on human labor for picking crops, offering flexibility and precision in delicate fruit handling but often resulting in slower harvesting speeds and higher labor costs. Robotic harvesting utilizes automated machinery equipped with sensors and AI software, enabling faster crop collection and continuous operation but facing limitations in adaptability to varying crop types and terrains. Key differences include labor dependency versus automation, cost efficiency over time, and the balance between harvesting accuracy and operational speed.

Advantages of Manual Harvesting

Manual harvesting offers superior precision and selectivity, allowing workers to carefully pick ripe fruits and vegetables with minimal damage, which preserves product quality. This method provides flexibility in handling crops of varying sizes and maturities that machines may not adequately distinguish. Labor-intensive but cost-effective for small-scale farms, manual harvesting supports local employment and reduces the initial investment required compared to robotic systems.

Benefits of Robotic Harvesting

Robotic harvesting increases efficiency by significantly reducing the time required to gather crops compared to manual methods, allowing for faster turnaround and higher productivity. It enhances precision in picking, minimizing crop damage and improving overall yield quality. Automated systems also reduce labor costs and mitigate the risks associated with human fatigue and labor shortages in agricultural operations.

Labor Costs and Workforce Challenges

Manual harvesting in agriculture demands significant labor costs due to the need for large workforces during peak seasons, often leading to increased wages and logistical challenges. Robotic harvesting technology reduces labor expenses by automating repetitive tasks, enhancing efficiency while addressing workforce shortages caused by aging populations and migrant labor restrictions. Implementing robotic systems mitigates dependency on seasonal labor fluctuations, resulting in more consistent harvest timelines and decreased overall operational costs.

Harvest Quality and Crop Handling Comparison

Manual harvesting allows skilled laborers to selectively pick ripe fruits and vegetables, minimizing damage and preserving quality through careful handling. Robotic harvesting employs advanced sensors and precision algorithms to reduce bruising and optimize crop selection, ensuring consistent quality even at high speeds. Comparatively, robotic systems enhance efficiency and maintain uniform crop handling, though manual methods still excel in delicate crop assessment and nuanced quality control.

Technological Innovations in Robotic Harvesters

Technological innovations in robotic harvesters have revolutionized manual harvesting by integrating advanced sensors, AI-based crop recognition, and precision navigation systems that significantly increase efficiency and reduce labor costs. These automated machines adapt to diverse crop types and harvesting conditions, enhancing yield quality through gentle handling and real-time data analytics. As a result, robotic harvesters contribute to sustainable farming practices by minimizing crop damage and optimizing harvest timing with minimal human intervention.

Environmental Impact of Harvesting Methods

Manual harvesting reduces soil compaction and fuel emissions compared to robotic harvesting, which often relies on heavy machinery powered by fossil fuels. Robotic harvesting can increase energy consumption and carbon footprint but offers precision that minimizes crop damage and reduces food waste. Sustainable practices in robotic systems, such as electric-powered harvesters, are emerging to mitigate environmental impacts.

Adoption Barriers and Implementation in Farms

Manual harvesting remains prevalent due to lower upfront costs and ease of workforce mobilization, yet labor shortages and rising wages accelerate interest in robotic harvesting technology. Adoption barriers for robotic systems include high initial investment, technological complexity, and the need for customization to diverse crop types and farm sizes. Successful implementation requires integrating machine learning algorithms with existing farm management systems and providing adequate training to operators for maximizing efficiency and minimizing downtime.

Future Trends in Agricultural Harvesting Techniques

Robotic harvesting technologies are rapidly advancing, driven by artificial intelligence, machine learning, and improved sensor capabilities, enabling precise and efficient crop collection with reduced labor dependency. Manual harvesting remains prevalent in small-scale farms due to cost-effectiveness and crop delicacy but faces challenges from labor shortages and rising wages. Future trends indicate increased integration of autonomous machines and drone-assisted harvesting, optimizing yield quality and operational sustainability.

Related Important Terms

Selective Robotic Picking

Selective robotic picking in agriculture enhances harvest precision by targeting ripe produce while minimizing crop damage, significantly improving yield quality compared to manual harvesting. Advanced sensors and AI technologies enable robots to identify and pick fruits selectively, increasing efficiency and reducing labor costs in diverse crop environments.

Real-Time Crop Sensing

Real-time crop sensing enhances robotic harvesting by providing precise data on crop maturity, health, and yield, enabling targeted picking with higher efficiency and minimal damage. Manual harvesting relies on human judgment, which can be inconsistent and slower, making real-time sensing critical for optimizing automated harvesting systems in precision agriculture.

Autonomous Fruit Detachment

Autonomous fruit detachment in robotic harvesting utilizes advanced sensors and machine learning algorithms to precisely identify and pick ripe fruits, significantly reducing labor costs and minimizing crop damage compared to manual harvesting. This technology enhances harvesting efficiency by operating continuously and adapting to varying fruit sizes and ripeness levels across diverse agricultural environments.

Human-Assisted Automation

Human-assisted automation in agriculture combines manual harvesting techniques with robotic technology to enhance precision and efficiency, reducing labor fatigue while maintaining crop quality. Integrating sensor-guided robotic arms with human supervision enables selective harvesting, optimizing yield and minimizing crop damage compared to fully manual or fully autonomous systems.

Gentle-Handling Grippers

Gentle-handling grippers in robotic harvesting significantly reduce fruit bruising and plant damage compared to manual harvesting, enhancing crop quality and yield. These advanced grippers utilize soft materials and precision sensors to mimic human touch, ensuring delicate produce are picked with minimal force and maximum care.

Precision End-Effector

Manual harvesting relies on human dexterity for selective crop picking, yet lacks the consistent precision of robotic harvesting equipped with advanced precision end-effectors designed for delicate handling and minimal crop damage. Precision end-effectors use sensor feedback and adaptive gripping mechanisms to optimize fruit picking efficiency, ensuring higher quality yield and reduced waste compared to traditional manual methods.

Labor-Displacement Metrics

Manual harvesting demands intensive human labor, with labor-displacement metrics showing a 70-80% reduction in workforce requirements when transitioning to robotic harvesting systems. Robotic harvesting improves efficiency by enabling continuous operation and reducing reliance on seasonal labor shortages, significantly lowering labor costs in large-scale agriculture.

Field-of-View Mapping

Manual harvesting relies on human labor to identify and collect crops, often limited by individual field-of-view and subjective judgment, leading to inconsistent yield mapping. Robotic harvesting utilizes advanced sensors and machine vision technology to create precise, scalable field-of-view maps, enhancing crop detection accuracy and optimizing harvest efficiency across large agricultural areas.

Bin Handling Integration

Manual harvesting limits bin handling efficiency due to slower human-paced loading and increased labor costs, impacting overall productivity. Robotic harvesting integrates automated bin handling systems that streamline crop transfer, reduce damage, and optimize workflow for higher operational throughput.

Adaptive Harvest Navigation

Adaptive harvest navigation in robotic harvesting utilizes GPS and AI-driven algorithms to precisely identify and pick crops, significantly reducing labor costs and increasing efficiency compared to manual harvesting. This technology enhances accuracy in navigating diverse field terrains and crop variations, enabling faster harvest cycles and minimizing damage to produce.

Manual harvesting vs Robotic harvesting Infographic

industrydif.com

industrydif.com