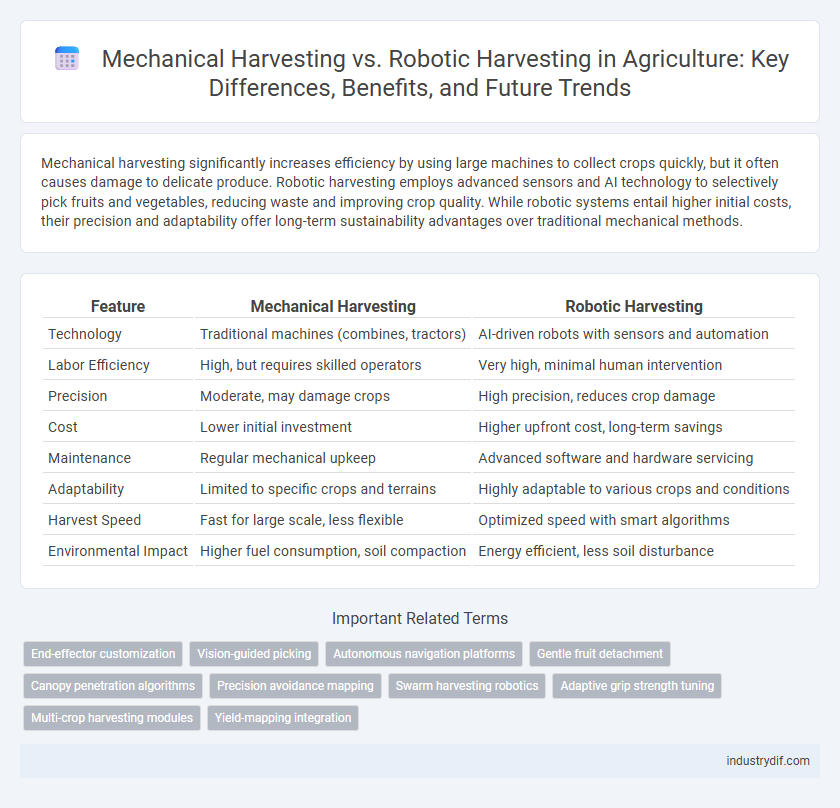

Mechanical harvesting significantly increases efficiency by using large machines to collect crops quickly, but it often causes damage to delicate produce. Robotic harvesting employs advanced sensors and AI technology to selectively pick fruits and vegetables, reducing waste and improving crop quality. While robotic systems entail higher initial costs, their precision and adaptability offer long-term sustainability advantages over traditional mechanical methods.

Table of Comparison

| Feature | Mechanical Harvesting | Robotic Harvesting |

|---|---|---|

| Technology | Traditional machines (combines, tractors) | AI-driven robots with sensors and automation |

| Labor Efficiency | High, but requires skilled operators | Very high, minimal human intervention |

| Precision | Moderate, may damage crops | High precision, reduces crop damage |

| Cost | Lower initial investment | Higher upfront cost, long-term savings |

| Maintenance | Regular mechanical upkeep | Advanced software and hardware servicing |

| Adaptability | Limited to specific crops and terrains | Highly adaptable to various crops and conditions |

| Harvest Speed | Fast for large scale, less flexible | Optimized speed with smart algorithms |

| Environmental Impact | Higher fuel consumption, soil compaction | Energy efficient, less soil disturbance |

Overview of Mechanical and Robotic Harvesting

Mechanical harvesting employs traditional machinery such as combines and harvesters designed for large-scale crop collection, emphasizing speed and efficiency in uniform fields. Robotic harvesting utilizes advanced sensors, artificial intelligence, and automation to selectively pick crops, improving precision and reducing labor costs, particularly in complex or delicate agricultural environments. Both methods aim to enhance productivity, but robotic systems offer adaptability and minimal crop damage compared to conventional mechanical harvesters.

Evolution of Harvesting Technologies in Agriculture

Mechanical harvesting revolutionized agriculture by significantly increasing efficiency and reducing labor costs with machines like combine harvesters introduced in the early 20th century. Advancements in sensor technology, artificial intelligence, and robotics have led to the emergence of robotic harvesting systems capable of precise, selective crop picking, minimizing damage and enabling round-the-clock operation. The evolution from bulky mechanical harvesters to intelligent robotic platforms marks a paradigm shift toward sustainable, high-tech farming practices that optimize yield and adapt to diverse crop requirements.

Key Components of Mechanical Harvesters

Mechanical harvesters rely on essential components such as cutting blades, conveyor belts, and threshing drums to efficiently separate crops from plants. These machines integrate powerful engines, hydraulic systems, and adjustable headers designed to accommodate various crop types and field conditions. Precision sensors and durable chassis enhance operational stability and productivity, making mechanical harvesters vital in large-scale agricultural operations.

Innovations in Robotic Harvesting Systems

Innovations in robotic harvesting systems include advanced machine vision, AI-driven crop assessment, and precision actuation, enabling selective picking and reduced crop damage compared to traditional mechanical harvesters. These robotic systems integrate sensors and real-time data analytics to adapt to diverse crop types and growth stages, enhancing yield efficiency and labor cost savings. Continuous development in autonomous navigation and end-effector technology ensures higher accuracy and operational flexibility in complex agricultural environments.

Efficiency Comparison: Mechanical vs Robotic Harvesting

Mechanical harvesting achieves high throughput by using large-scale machines designed for specific crops, often reducing labor costs but can cause crop damage and inefficiencies in irregular fields. Robotic harvesting leverages AI and precision sensors to selectively pick fruits or vegetables, significantly improving harvest accuracy and reducing waste, though current speeds may lag behind mechanical systems. Emerging advancements in robotics promise increased operational efficiency and adaptability, potentially surpassing traditional mechanical harvesters in both productivity and crop quality preservation.

Labor Cost Implications in Modern Harvesting

Mechanical harvesting reduces labor costs by utilizing machinery that can operate continuously and handle large volumes of crops with minimal human intervention. Robotic harvesting further optimizes labor expenses by automating complex tasks such as selective picking and sorting, which decreases reliance on skilled labor and reduces human error. Both technologies contribute to significant labor cost savings, but robotic systems offer greater precision and adaptability, making them particularly viable for labor-intensive crops.

Crop Suitability: Mechanical vs Robotic Approaches

Mechanical harvesting excels in crops like wheat, corn, and soybeans due to its efficiency in large-scale, uniform fields, offering rapid collection but limited precision. Robotic harvesting is better suited for delicate or irregularly shaped crops such as strawberries, tomatoes, and grapes, providing precision and minimizing damage through advanced sensors and AI-driven manipulation. Crop suitability depends on factors like plant fragility, field heterogeneity, and harvest timing, where robotics offers adaptability and mechanical methods prioritize speed.

Environmental Impact of Advanced Harvesting Methods

Mechanical harvesting reduces soil compaction and fuel consumption compared to traditional methods, yet still relies on fossil fuels which contribute to greenhouse gas emissions. Robotic harvesting employs electric-powered, precise machinery that minimizes crop damage and decreases energy use, leading to lower carbon footprints and less chemical runoff. Adoption of robotic systems supports sustainable farming by enhancing resource efficiency and reducing environmental degradation.

Challenges and Limitations in Automation Adoption

Mechanical harvesting faces challenges such as crop damage due to lack of precision and adaptability to diverse plant varieties, limiting its effectiveness across different agricultural contexts. Robotic harvesting struggles with high initial costs, complex sensor integration, and difficulties in navigating unstructured environments, which slow widespread adoption. Both methods require advancements in AI and machine learning to overcome limitations in real-time decision-making and efficient crop handling.

Future Trends in Agricultural Harvesting Technology

Mechanical harvesting continues to evolve with advancements in precision farming technologies, enhancing efficiency and reducing labor costs across large-scale crop production. Robotic harvesting is emerging as a transformative trend, utilizing AI-powered sensors and machine learning algorithms to navigate complex crop environments and perform selective picking with minimal human intervention. The integration of IoT and autonomous systems is expected to accelerate, driving sustainable and highly adaptive harvesting solutions in future agricultural practices.

Related Important Terms

End-effector customization

Mechanical harvesting relies on standardized end-effectors designed for speed and durability in mass crop collection, while robotic harvesting enables advanced end-effector customization tailored to specific crop types and delicate handling requirements. Enhanced precision in robotic end-effectors improves fruit quality preservation and reduces crop damage, optimizing overall agricultural yield and efficiency.

Vision-guided picking

Mechanical harvesting relies on fixed machinery designed for uniform crop types, offering high-speed bulk harvesting but limited precision. Vision-guided robotic harvesting uses advanced imaging sensors and AI algorithms to identify and selectively pick ripe fruits, enhancing accuracy and reducing crop damage in diverse agricultural environments.

Autonomous navigation platforms

Mechanical harvesting relies on GPS-guided tractors and combines for efficient crop collection over large areas, while robotic harvesting systems utilize advanced autonomous navigation platforms combined with computer vision and AI to selectively pick fruits or vegetables with high precision and minimal crop damage. These autonomous navigation platforms integrate LiDAR, machine learning algorithms, and real-time sensor data to optimize path planning, adapt to variable field conditions, and increase operational efficiency in complex agricultural environments.

Gentle fruit detachment

Mechanical harvesting often causes fruit bruising and damage due to generalized shaking or cutting, whereas robotic harvesting employs precise sensors and soft grippers to ensure gentle fruit detachment, preserving fruit quality and minimizing waste. Advances in machine vision and AI-driven control systems enable robotic harvesters to identify optimal picking points and apply minimal force, significantly reducing post-harvest losses in delicate crops like strawberries and tomatoes.

Canopy penetration algorithms

Canopy penetration algorithms enhance mechanical harvesting by optimizing tool alignment for efficient crop access and minimizing damage to plants. Robotic harvesting leverages advanced canopy penetration algorithms integrated with AI sensors to identify fruit location and adjust movements precisely, improving yield quality and operational speed.

Precision avoidance mapping

Mechanical harvesting relies on predefined pathways for crop collection, often resulting in unintended plant damage due to limited adaptability. Robotic harvesting utilizes precision avoidance mapping powered by advanced sensors and AI algorithms, enabling targeted crop selection while minimizing harm to surrounding flora.

Swarm harvesting robotics

Swarm harvesting robotics leverage coordinated autonomous machines to enhance efficiency and precision in agricultural harvesting, significantly reducing labor costs and crop damage compared to traditional mechanical harvesting systems. These intelligent robotic swarms enable scalable, real-time decision-making and adaptability to varied crop types and field conditions, driving innovation in sustainable agriculture.

Adaptive grip strength tuning

Mechanical harvesting relies on fixed grip strength settings that can cause damage to delicate crops, while robotic harvesting systems use adaptive grip strength tuning to optimize pressure based on crop type and ripeness, reducing bruising and product loss. Advanced sensors and AI algorithms enable robotic harvesters to dynamically adjust their grip, enhancing precision and efficiency in fruit picking and vegetable harvesting.

Multi-crop harvesting modules

Mechanical harvesting systems equipped with multi-crop modules enhance efficiency by adapting to various crop types through interchangeable components and adjustable settings, reducing downtime and labor costs. Robotic harvesting leverages AI-driven sensors and precision actuators to selectively pick multiple crops in mixed farming environments, optimizing yield quality and minimizing crop damage.

Yield-mapping integration

Mechanical harvesting employs traditional machinery equipped with GPS and basic sensors for yield mapping, enabling real-time data collection on crop performance. Robotic harvesting integrates advanced AI-driven sensors and machine learning algorithms for precise yield-mapping, enhancing data accuracy and enabling detailed crop variability analysis at a micro-scale.

Mechanical Harvesting vs Robotic Harvesting Infographic

industrydif.com

industrydif.com