Tractor plowing remains a reliable method for preparing soil, offering manual control and adaptability across varied terrains, but it demands significant operator skill and labor. Autonomous tractors leverage GPS technology and AI to optimize plowing efficiency, reduce human error, and operate continuously, enhancing productivity on large-scale farms. However, integrating autonomous systems requires substantial investment and technical support, making the choice dependent on farm size and budget constraints.

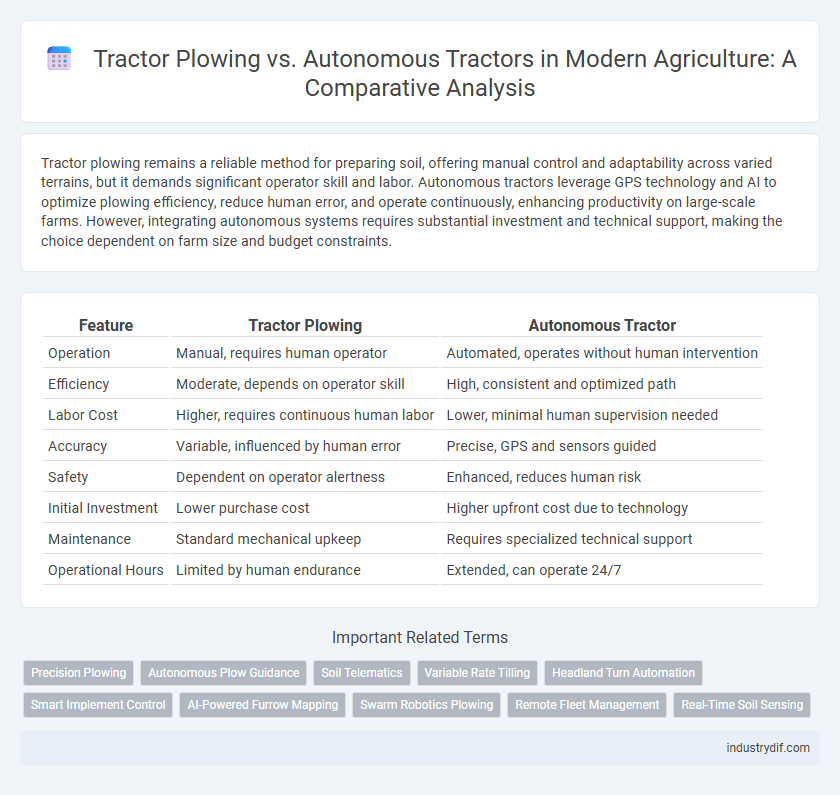

Table of Comparison

| Feature | Tractor Plowing | Autonomous Tractor |

|---|---|---|

| Operation | Manual, requires human operator | Automated, operates without human intervention |

| Efficiency | Moderate, depends on operator skill | High, consistent and optimized path |

| Labor Cost | Higher, requires continuous human labor | Lower, minimal human supervision needed |

| Accuracy | Variable, influenced by human error | Precise, GPS and sensors guided |

| Safety | Dependent on operator alertness | Enhanced, reduces human risk |

| Initial Investment | Lower purchase cost | Higher upfront cost due to technology |

| Maintenance | Standard mechanical upkeep | Requires specialized technical support |

| Operational Hours | Limited by human endurance | Extended, can operate 24/7 |

Evolution of Tractor Plowing in Modern Agriculture

Tractor plowing has evolved from manual, labor-intensive methods to advanced mechanized systems enhancing soil preparation efficiency and crop yield. Autonomous tractors integrate GPS technology, AI, and precision farming techniques, reducing human error and operational costs while optimizing resource use. This evolution drives sustainable farming by improving field management and enabling data-driven decision-making in modern agriculture.

Introduction to Autonomous Tractors: Key Features

Autonomous tractors integrate GPS technology, advanced sensors, and AI-driven software to perform plowing tasks with precision and minimal human intervention. These tractors optimize field coverage through real-time data analysis, reducing soil compaction and fuel consumption compared to traditional tractor plowing methods. Enhanced safety features and remote monitoring capabilities increase operational efficiency and allow for continuous work during various weather conditions.

Efficiency Comparison: Traditional vs Autonomous Plowing

Traditional tractor plowing requires manual operation, leading to variability in efficiency based on operator skill and fatigue. Autonomous tractors utilize GPS and sensor technology to maintain consistent speed and depth, optimizing fuel use and reducing soil compaction. Studies show autonomous plowing can increase field productivity by up to 20%, while minimizing human error and operational downtime.

Labor Costs: Manual Operation vs Automation

Manual tractor plowing requires significant labor costs due to operator wages, fatigue, and limited working hours, impacting overall farm productivity. Autonomous tractors reduce labor expenses by enabling continuous operation without breaks and minimizing human intervention, leading to higher efficiency and cost savings. Adoption of automated systems shifts investment towards technology maintenance and monitoring, balancing initial costs with long-term labor reductions.

Precision Agriculture: Enhanced Accuracy with Autonomous Tractors

Autonomous tractors leverage GPS technology and advanced sensors to achieve centimeter-level accuracy in plowing, significantly reducing overlaps and missed areas compared to traditional tractor plowing. This precision agriculture approach enables optimized seed placement and soil management, resulting in higher crop yields and reduced input costs. Enhanced data integration with autonomous tractors supports real-time field mapping and variable rate applications, improving overall farm efficiency.

Fuel Consumption and Environmental Impact

Tractor plowing with traditional diesel engines typically consumes more fuel and emits higher levels of greenhouse gases compared to autonomous tractors, which often utilize advanced fuel-efficient technologies or electric powertrains. Autonomous tractors optimize fuel consumption by maintaining consistent speeds and precise routes, reducing soil compaction and carbon emissions. This efficiency lowers the environmental footprint of agricultural practices, promoting sustainable farming through decreased fossil fuel dependence and minimized air pollution.

Safety Considerations in Tractor Operation

Tractor plowing involves direct human control, which increases the risk of operator fatigue and accidents due to manual handling and environmental hazards. Autonomous tractors reduce these risks by using advanced sensors and AI to navigate fields safely, minimizing human error and exposure to dangerous conditions. Enhanced safety features in autonomous systems include obstacle detection, automatic shutdown in emergencies, and constant monitoring, significantly improving overall operational safety in agriculture.

Adoption Barriers for Autonomous Tractors

Autonomous tractors face significant adoption barriers in agriculture, including high initial investment costs and the complexity of integration with existing farm management systems. Limited wireless connectivity in rural areas hampers real-time data transmission and remote monitoring essential for autonomous operations. Moreover, farmers' skepticism regarding safety, reliability, and the lack of technical support slows widespread acceptance and deployment.

Maintenance and Technical Support Differences

Tractor plowing requires regular maintenance such as oil changes, engine tune-ups, and hydraulic system checks, often necessitating hands-on technical support from experienced mechanics. Autonomous tractors rely heavily on software updates, sensor calibration, and troubleshooting high-tech components, demanding specialized technicians proficient in robotics and AI systems. Maintenance intervals for traditional tractors tend to be more predictable, while autonomous models require continuous monitoring to ensure optimal algorithm performance and sensor accuracy.

Future Trends in Plowing Technology

Future trends in plowing technology emphasize the integration of autonomous tractors equipped with GPS and AI-driven systems to enhance precision and efficiency. These innovations reduce fuel consumption and soil compaction compared to traditional tractor plowing, promoting sustainable agricultural practices. Advancements in sensor technology and machine learning enable real-time monitoring and adaptive responses to varying soil conditions, driving the evolution of smart farming.

Related Important Terms

Precision Plowing

Tractor plowing relies on operator skill for soil depth and alignment, potentially causing inconsistencies, while autonomous tractors use GPS and sensor technology for precision plowing, ensuring uniform soil preparation and optimized seedbed conditions. Precision plowing with autonomous tractors enhances fuel efficiency, reduces soil compaction, and improves crop yields by maintaining accurate furrow spacing and depth control throughout the field.

Autonomous Plow Guidance

Autonomous plow guidance systems in tractors enhance precision farming by utilizing GPS and advanced sensors to optimize plowing patterns, significantly reducing soil compaction and fuel consumption compared to traditional tractor plowing. These systems increase operational efficiency, minimize human error, and enable real-time adjustments, promoting sustainable agricultural practices and higher crop yields.

Soil Telematics

Soil telematics in tractor plowing allows real-time monitoring of soil conditions, optimizing manual tractor adjustments for improved crop yields. Autonomous tractors equipped with advanced soil telematics analyze moisture, compaction, and nutrient levels continuously, enabling precise, adaptive plowing that enhances soil health and operational efficiency.

Variable Rate Tilling

Variable rate tilling using traditional tractor plowing requires manual adjustments based on soil and crop variability, often leading to inconsistent application and increased labor costs. Autonomous tractors equipped with precision sensors optimize variable rate tilling by automatically adjusting tillage depth and speed in real-time, enhancing soil health, reducing fuel consumption, and improving crop yields.

Headland Turn Automation

Headland turn automation in autonomous tractors significantly reduces operator fatigue and increases precision during plowing by automatically controlling steering and speed adjustments at field boundaries. Tractor plowing with manual headland turns demands constant human input, which can lead to inconsistencies and inefficiencies in field coverage.

Smart Implement Control

Tractor plowing with Smart Implement Control optimizes tillage precision by automatically adjusting blade depth and speed according to soil conditions, enhancing efficiency and reducing fuel consumption. Autonomous tractors equipped with Smart Implement Control offer improved operational accuracy and real-time data integration, enabling adaptive responses to field variability for increased crop yield and minimized soil compaction.

AI-Powered Furrow Mapping

AI-powered furrow mapping in autonomous tractors enhances precision agriculture by utilizing advanced sensors and machine learning algorithms to create accurate soil and terrain models, optimizing plowing depth and spacing for improved crop yields. Compared to traditional tractor plowing, this technology reduces operator error, increases efficiency, and enables real-time adjustments to varying field conditions for sustainable soil management.

Swarm Robotics Plowing

Swarm robotics plowing enhances agricultural efficiency by coordinating multiple autonomous tractors to work simultaneously, enabling faster soil cultivation and improved resource management compared to traditional tractor plowing. This technology optimizes field coverage, reduces fuel consumption, and increases crop yield through precise, data-driven operations.

Remote Fleet Management

Tractor plowing demands manual oversight and on-site adjustments, while autonomous tractors integrate advanced remote fleet management systems enabling real-time monitoring, route optimization, and predictive maintenance. This digital transformation increases operational efficiency, reduces labor costs, and enhances precision agriculture outcomes through centralized control of multiple autonomous units.

Real-Time Soil Sensing

Tractor plowing relies on manual adjustment and operator experience to respond to soil conditions, often resulting in variable efficiency and potential soil compaction. Autonomous tractors equipped with real-time soil sensing technology continuously monitor soil moisture, texture, and resistance, enabling precise adjustments that optimize plowing depth and speed for improved crop yield and sustainable soil health.

Tractor Plowing vs Autonomous Tractor Infographic

industrydif.com

industrydif.com