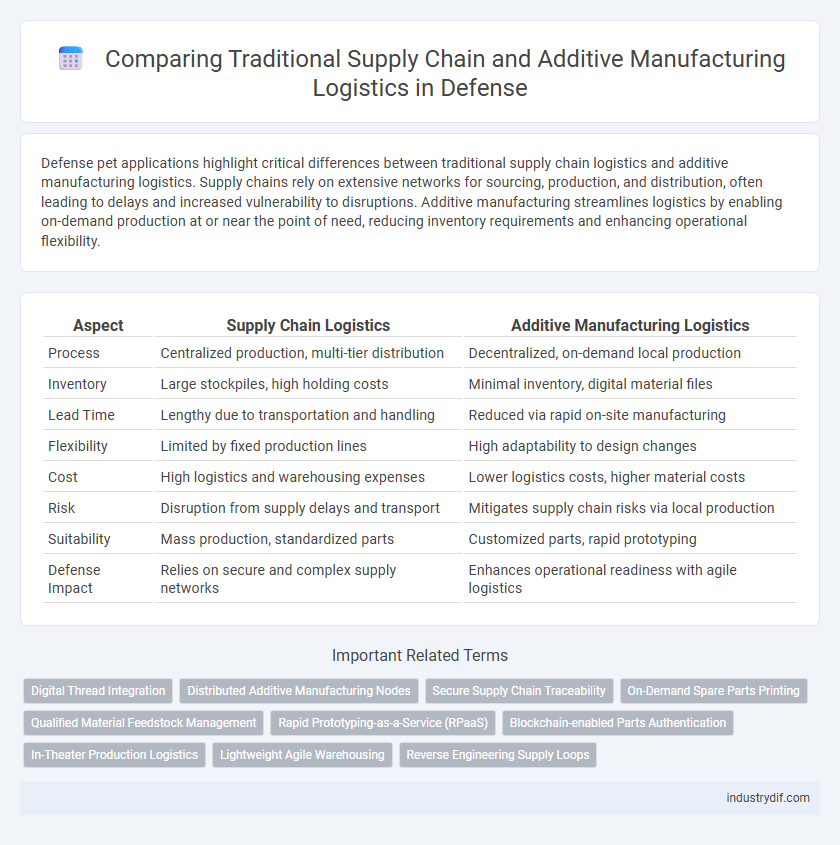

Defense pet applications highlight critical differences between traditional supply chain logistics and additive manufacturing logistics. Supply chains rely on extensive networks for sourcing, production, and distribution, often leading to delays and increased vulnerability to disruptions. Additive manufacturing streamlines logistics by enabling on-demand production at or near the point of need, reducing inventory requirements and enhancing operational flexibility.

Table of Comparison

| Aspect | Supply Chain Logistics | Additive Manufacturing Logistics |

|---|---|---|

| Process | Centralized production, multi-tier distribution | Decentralized, on-demand local production |

| Inventory | Large stockpiles, high holding costs | Minimal inventory, digital material files |

| Lead Time | Lengthy due to transportation and handling | Reduced via rapid on-site manufacturing |

| Flexibility | Limited by fixed production lines | High adaptability to design changes |

| Cost | High logistics and warehousing expenses | Lower logistics costs, higher material costs |

| Risk | Disruption from supply delays and transport | Mitigates supply chain risks via local production |

| Suitability | Mass production, standardized parts | Customized parts, rapid prototyping |

| Defense Impact | Relies on secure and complex supply networks | Enhances operational readiness with agile logistics |

Overview of Defense Supply Chain Logistics

Defense supply chain logistics involve the coordinated management of materials, transportation, and inventory to ensure operational readiness across military forces. Traditional supply chains rely heavily on centralized manufacturing and long lead times, which can be vulnerable to disruptions in conflict zones or geopolitical instability. Additive manufacturing logistics offer a transformative approach by enabling on-demand production of critical parts at or near the point of use, reducing dependency on extended supply lines and enhancing tactical flexibility.

Introduction to Additive Manufacturing in Defense

Additive manufacturing in defense revolutionizes traditional supply chain logistics by enabling on-demand production of critical components directly at or near the point of use, significantly reducing lead times and inventory costs. This technology supports rapid prototyping, customization, and repair of mission-essential parts, enhancing operational readiness and resilience in austere environments. By integrating additive manufacturing, defense logistics transform from linear, centralized processes to agile, decentralized networks capable of responding swiftly to evolving tactical requirements.

Traditional vs Additive Manufacturing Supply Chains

Traditional manufacturing supply chains in defense rely heavily on multi-tiered suppliers, long lead times, and complex logistics, increasing vulnerability to disruptions and delays. Additive manufacturing logistics streamline production by enabling on-demand, localized part fabrication, significantly reducing inventory requirements and transportation costs. This shift enhances operational flexibility and resilience by allowing military units to produce critical components directly in the field, minimizing dependence on extended supply chains.

Key Terminologies in Defense Logistics

Supply chain logistics in defense encompasses procurement, inventory management, and distribution of materials essential for military operations, emphasizing resilience and responsiveness. Additive manufacturing logistics involves on-demand production techniques like 3D printing, reducing lead times and enabling rapid prototyping and replacement parts fabrication at or near the point of use. Key terminologies include Just-In-Time (JIT) delivery, Total Asset Visibility (TAV), and Digital Thread integration, which are critical for synchronizing traditional supply networks with advanced manufacturing processes.

Strategic Sourcing in Defense Supply Chains

Strategic sourcing in defense supply chains leverages additive manufacturing logistics to reduce dependency on traditional suppliers and mitigate supply chain disruptions. By integrating 3D printing capabilities, defense organizations achieve greater flexibility in producing critical components on-demand, ensuring rapid response to operational needs. This approach optimizes inventory management, lowers procurement costs, and enhances supply chain resilience against geopolitical uncertainties.

Impact of Additive Manufacturing on Defense Logistics

Additive manufacturing revolutionizes defense logistics by enabling on-demand production of critical components, reducing dependency on extended supply chains and mitigating risks associated with transportation delays or disruptions. This technology enhances operational readiness by allowing rapid prototyping and localized manufacturing, which decreases inventory requirements and shortens lead times for spare parts. Integration of additive manufacturing into defense supply chains significantly improves mission flexibility and cost-efficiency by minimizing logistical footprints and streamlining maintenance workflows.

Inventory Management: Conventional vs Additive Methods

Traditional supply chain logistics in defense relies heavily on extensive inventory management, maintaining large stockpiles to ensure readiness and minimize downtime. Additive manufacturing logistics streamline inventory by enabling on-demand production of parts, significantly reducing storage costs and obsolescence risks. This shift from conventional bulk inventory to digital inventory and localized production enhances operational agility and responsiveness in defense logistics.

Risk Mitigation in Defense Supply Chains

Risk mitigation in defense supply chains is enhanced by integrating additive manufacturing, which reduces dependency on complex global supply networks and minimizes lead times for critical components. Additive manufacturing enables on-demand production of spare parts at or near deployment sites, mitigating risks associated with transportation delays, supplier disruptions, and geopolitical constraints. By decentralizing production capabilities, defense logistics achieve improved resilience, flexibility, and responsiveness in maintaining operational readiness.

Lead Time Reduction through Additive Manufacturing

Additive manufacturing significantly reduces lead times in defense logistics by enabling on-demand production of parts directly at or near the point of need, bypassing lengthy traditional supply chains. This technology minimizes delays caused by long-distance shipping and complex supplier networks, accelerating maintenance and repair operations. Rapid prototyping and localized manufacturing also ensure faster responsiveness to mission-critical requirements, enhancing overall operational readiness.

Future Trends in Defense Supply Chain and Additive Logistics

Future trends in defense supply chain emphasize the integration of additive manufacturing logistics to enhance operational agility and reduce production lead times. Advanced technologies such as 3D printing enable on-demand fabrication of critical components, minimizing dependency on traditional supply routes and improving mission readiness. Embracing additive manufacturing fosters resilient, decentralized logistics networks capable of adapting to dynamic combat environments and supply disruptions.

Related Important Terms

Digital Thread Integration

Integrating digital thread technology enhances visibility and traceability in both supply chain and additive manufacturing logistics, enabling real-time data exchange and synchronized operations across defense production lines. This seamless connectivity reduces lead times, optimizes inventory management, and supports rapid prototyping by linking design, production, and maintenance processes within a unified digital framework.

Distributed Additive Manufacturing Nodes

Distributed additive manufacturing nodes enhance defense supply chain resilience by enabling on-demand, localized production of critical components, reducing dependency on traditional logistics and minimizing lead times. This decentralized approach optimizes inventory management and supports rapid deployment in austere environments, thereby increasing operational readiness and flexibility.

Secure Supply Chain Traceability

Secure supply chain traceability in defense logistics enhances the integrity of material procurement by integrating blockchain technology and IoT sensors, enabling real-time tracking and authentication of components from origin to deployment. Additive manufacturing logistics streamline on-demand production with embedded digital fingerprints, reducing dependency on traditional supply chains and minimizing risks of counterfeit parts in critical defense applications.

On-Demand Spare Parts Printing

On-demand spare parts printing in additive manufacturing revolutionizes defense logistics by reducing supply chain dependency and minimizing inventory costs while enabling rapid response to maintenance needs. This technology streamlines part availability directly at deployment sites, enhancing operational readiness and decreasing downtime in critical defense systems.

Qualified Material Feedstock Management

Qualified material feedstock management in defense supply chains ensures consistent quality and traceability, critical for mission readiness and compliance with stringent military standards. Additive manufacturing logistics streamline this process by enabling on-demand production, reducing dependency on extensive inventories and minimizing supply chain vulnerabilities.

Rapid Prototyping-as-a-Service (RPaaS)

Rapid Prototyping-as-a-Service (RPaaS) revolutionizes defense supply chains by enabling on-demand production of critical components, reducing lead times from weeks to hours and minimizing dependency on complex logistics networks. Integrating RPaaS with additive manufacturing logistics enhances operational agility, allowing decentralized manufacturing that supports dynamic battlefield requirements and improves overall mission readiness.

Blockchain-enabled Parts Authentication

Blockchain-enabled parts authentication enhances supply chain security by providing immutable records that verify the provenance and integrity of components, reducing counterfeit risks in defense logistics. Additive manufacturing logistics benefit from this technology by ensuring rapid, on-demand production parts are authenticated and traceable throughout the digital supply chain, improving readiness and operational resilience.

In-Theater Production Logistics

In-theater production logistics for defense operations benefit significantly from additive manufacturing by reducing dependency on traditional supply chains, enabling rapid, on-demand fabrication of critical parts directly within the combat zone. This shift enhances operational readiness by minimizing lead times, transportation risks, and inventory costs associated with conventional supply chain logistics.

Lightweight Agile Warehousing

Lightweight agile warehousing in defense supply chains reduces inventory footprint and accelerates deployment by integrating additive manufacturing for on-demand parts production. This approach enhances operational readiness by minimizing transportation logistics and supporting rapid customization across distributed units.

Reverse Engineering Supply Loops

Reverse engineering supply loops in defense logistics enhances resilience by enabling the reproduction of critical components through additive manufacturing, reducing dependency on traditional supply chains prone to disruption. This approach accelerates maintenance cycles and ensures continuous operational readiness by leveraging digital twins and on-demand production capabilities.

Supply Chain vs Additive Manufacturing Logistics Infographic

industrydif.com

industrydif.com