Traditional conductors, such as copper and aluminum, offer excellent electrical conductivity but face limitations in flexibility and weight. Carbon nanotube conductors provide superior mechanical strength, lightweight properties, and enhanced electron mobility, making them promising alternatives for next-generation electrical applications. Their nanoscale structure enables improved current carrying capacity and durability in extreme conditions.

Table of Comparison

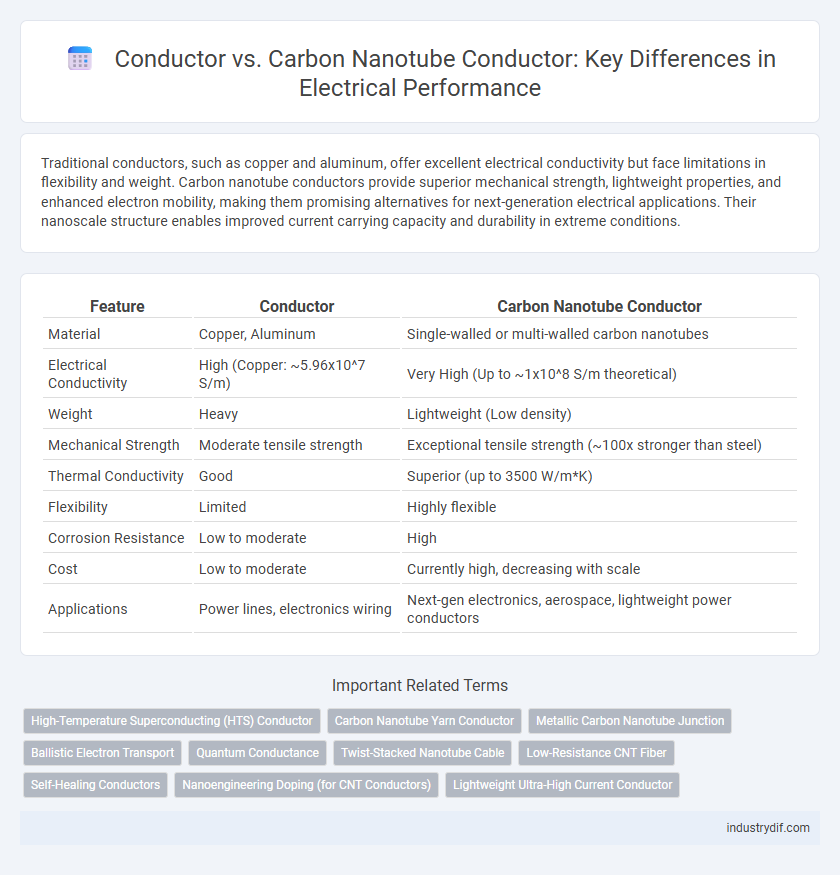

| Feature | Conductor | Carbon Nanotube Conductor |

|---|---|---|

| Material | Copper, Aluminum | Single-walled or multi-walled carbon nanotubes |

| Electrical Conductivity | High (Copper: ~5.96x10^7 S/m) | Very High (Up to ~1x10^8 S/m theoretical) |

| Weight | Heavy | Lightweight (Low density) |

| Mechanical Strength | Moderate tensile strength | Exceptional tensile strength (~100x stronger than steel) |

| Thermal Conductivity | Good | Superior (up to 3500 W/m*K) |

| Flexibility | Limited | Highly flexible |

| Corrosion Resistance | Low to moderate | High |

| Cost | Low to moderate | Currently high, decreasing with scale |

| Applications | Power lines, electronics wiring | Next-gen electronics, aerospace, lightweight power conductors |

Introduction to Electrical Conductors

Electrical conductors are materials that allow the flow of electric current with minimal resistance, typically metals such as copper and aluminum known for their high electrical conductivity. Carbon nanotube conductors, composed of cylindrical carbon molecules, exhibit exceptional electrical properties, including higher current density and flexibility compared to traditional metal conductors. The superior electron mobility and nanoscale dimension of carbon nanotubes offer significant advantages in developing next-generation electrical wiring and components.

Overview of Conventional Metal Conductors

Conventional metal conductors such as copper and aluminum are widely used in electrical wiring due to their excellent electrical conductivity and relatively low cost. These metals offer good tensile strength and thermal stability, making them suitable for a variety of applications including power transmission and electronic devices. However, their weight and susceptibility to corrosion limit performance compared to emerging alternatives like carbon nanotube conductors.

What Are Carbon Nanotube Conductors?

Carbon nanotube conductors consist of cylindrical nanostructures made from rolled graphene sheets, exhibiting exceptional electrical conductivity and mechanical strength compared to traditional metal conductors like copper or aluminum. These conductors enable enhanced electron mobility and reduced power loss, making them ideal for advanced electrical applications and flexible electronics. Their nanoscale dimensions and high aspect ratios contribute to improved durability, heat resistance, and lightweight properties in electrical transmission systems.

Electrical Conductivity: Copper vs. Carbon Nanotubes

Copper exhibits an electrical conductivity of approximately 5.96 x 10^7 S/m, making it one of the most efficient traditional conductors for electrical wiring and components. Carbon nanotubes (CNTs) demonstrate remarkable electrical conductivity, with values reaching up to 10^8 S/m in certain configurations, surpassing copper in nanoscale applications. The unique one-dimensional structure of CNTs enables ballistic electron transport, reducing resistance and heat generation compared to conventional copper conductors.

Mechanical Strength and Durability Comparison

Conventional metal conductors like copper and aluminum offer good electrical conductivity but suffer from mechanical limitations such as susceptibility to fatigue and deformation under stress. Carbon nanotube (CNT) conductors exhibit exceptional mechanical strength, boasting tensile strength up to 100 times greater than steel while maintaining excellent flexibility and resilience. This superior durability makes CNT conductors highly resistant to mechanical wear, cyclic loading, and environmental degradation, positioning them as promising alternatives for robust, long-lasting electrical applications.

Flexibility and Weight Differences

Carbon nanotube conductors exhibit significantly greater flexibility compared to traditional metal conductors, allowing for bending and twisting without performance degradation. Their ultralight weight, often less than one-tenth that of copper wires, enhances efficiency in portable and wearable electronic devices. This combination of superior flexibility and minimal mass makes carbon nanotube conductors ideal for advanced electrical applications where durability and weight reduction are critical.

Thermal Conductivity Characteristics

Traditional metal conductors like copper exhibit high electrical conductivity but relatively moderate thermal conductivity, typically around 400 W/m*K. Carbon nanotube conductors demonstrate exceptional thermal conductivity, with values exceeding 3000 W/m*K, enabling superior heat dissipation in electrical applications. This remarkable thermal performance of carbon nanotubes reduces overheating risks and enhances the reliability and efficiency of electronic devices.

Scalability and Manufacturing Challenges

Traditional metal conductors like copper are widely used due to their established large-scale manufacturing processes and cost-effective scalability. Carbon nanotube conductors offer superior electrical conductivity and flexibility but face significant challenges in mass production, including uniformity, alignment, and integration into existing manufacturing systems. Overcoming these hurdles is critical to scaling carbon nanotube-based conductors for widespread electrical applications.

Industry Applications and Use Cases

Copper and aluminum conductors dominate traditional electrical wiring due to their excellent conductivity and cost-effectiveness in power transmission and distribution. Carbon nanotube conductors, with superior strength-to-weight ratios and exceptional electrical conductivity, are increasingly employed in aerospace wiring, flexible electronics, and high-frequency signal transmission where weight reduction and durability are critical. Industries advancing wearable technology and next-generation energy storage systems leverage carbon nanotube conductors to enhance performance and efficiency beyond conventional metal conductors.

Future Trends in Conductor Technology

Carbon nanotube conductors exhibit significantly higher electrical conductivity and mechanical strength compared to traditional metal conductors such as copper and aluminum. Future trends in conductor technology emphasize the integration of carbon nanotubes to enhance efficiency, reduce weight, and improve thermal management in electrical systems. Advancements in scalable manufacturing processes will accelerate the adoption of carbon nanotube conductors in power transmission and flexible electronic applications.

Related Important Terms

High-Temperature Superconducting (HTS) Conductor

High-Temperature Superconducting (HTS) conductors demonstrate significantly lower electrical resistance at elevated temperatures compared to conventional copper conductors and emerging carbon nanotube conductors, enabling greater energy efficiency and higher current densities in power transmission. Carbon nanotube conductors exhibit exceptional tensile strength and flexibility but currently lack the superconducting properties and thermal stability of HTS materials, limiting their practical application in high-performance electrical grids.

Carbon Nanotube Yarn Conductor

Carbon nanotube yarn conductors exhibit exceptional electrical conductivity combined with lightweight and flexibility, surpassing traditional metal conductors like copper and aluminum. Their nanoscale structure provides high tensile strength and thermal stability, making them ideal for advanced electronic, aerospace, and wearable technologies.

Metallic Carbon Nanotube Junction

Metallic carbon nanotube junctions exhibit superior electrical conductivity and reduced resistance compared to traditional metal conductors, enabling more efficient electron transport at the nanoscale. These junctions leverage the unique quantum conductance properties of carbon nanotubes, offering enhanced performance for next-generation conductive materials in electricity transmission.

Ballistic Electron Transport

Ballistic electron transport in carbon nanotube conductors offers near-zero resistance and minimal electron scattering compared to traditional metal conductors, enabling higher current densities and faster electron mobility. This efficient charge transport mechanism allows carbon nanotubes to outperform copper and aluminum conductors in nanoscale and high-frequency electrical applications.

Quantum Conductance

Quantum conductance in traditional metal conductors relies on electron scattering within bulk materials, limiting conductivity at nanoscale dimensions, whereas carbon nanotube conductors exhibit near-ballistic transport with quantized conductance channels due to their unique one-dimensional structure and strong quantum confinement effects. Carbon nanotubes achieve conductance values close to multiples of the conductance quantum (2e2/h), offering exceptional electron mobility and minimal resistance ideal for nanoscale electrical interconnects and advanced nanoelectronic devices.

Twist-Stacked Nanotube Cable

Twist-stacked carbon nanotube cables exhibit superior electrical conductivity and mechanical strength compared to traditional metal conductors, enabling efficient current flow in compact, flexible designs. Their nanoscale twist-stacking structure minimizes electron scattering and enhances charge transport, positioning these cables as promising alternatives for high-performance electrical applications.

Low-Resistance CNT Fiber

Low-resistance carbon nanotube (CNT) fiber exhibits superior electrical conductivity and mechanical strength compared to traditional metal conductors like copper and aluminum, making it an emerging material for efficient power transmission. CNT fibers' unique nanoscale structure enables electron transport with minimal resistance and enhanced flexibility, significantly reducing energy loss in electrical circuits.

Self-Healing Conductors

Traditional metal conductors face durability challenges due to physical damage and thermal stress, while carbon nanotube conductors exhibit self-healing properties by autonomously restoring electrical pathways through reconfiguration of their nanoscale structure. This intrinsic self-healing ability enhances the lifespan and reliability of electrical systems, making carbon nanotube conductors a transformative innovation in advanced electricity transmission and electronic device applications.

Nanoengineering Doping (for CNT Conductors)

Carbon nanotube (CNT) conductors exhibit superior electrical conductivity and mechanical flexibility compared to traditional metal conductors, largely due to precise nanoengineering doping techniques that enhance charge carrier density and reduce resistive losses. Controlled doping of CNTs with elements such as nitrogen or boron strategically modifies their electronic band structure, enabling tailored conductivity and improved performance in nanoscale electrical applications.

Lightweight Ultra-High Current Conductor

Carbon nanotube conductors exhibit exceptional strength-to-weight ratios and ultra-high current-carrying capacity, surpassing traditional metal conductors by offering significantly reduced weight while maintaining superior electrical conductivity. These lightweight ultra-high current conductors enhance energy efficiency in power transmission and electric vehicles by minimizing resistive losses and enabling compact, durable wiring solutions.

Conductor vs Carbon nanotube conductor Infographic

industrydif.com

industrydif.com