Electromechanical relays use physical contacts to switch electrical circuits, providing reliable isolation but are prone to wear and slower operation. Solid-state relays rely on semiconductor components, offering faster switching speeds, longer lifespan, and silent operation without mechanical parts. Choosing between them depends on factors like switching frequency, load type, and environmental conditions.

Table of Comparison

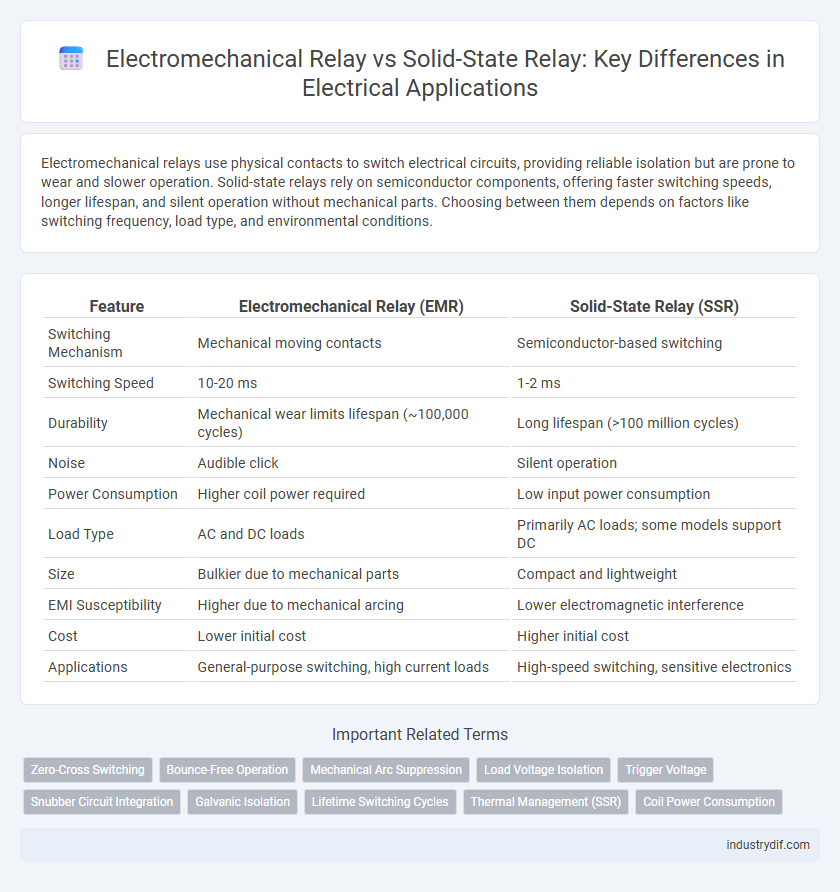

| Feature | Electromechanical Relay (EMR) | Solid-State Relay (SSR) |

|---|---|---|

| Switching Mechanism | Mechanical moving contacts | Semiconductor-based switching |

| Switching Speed | 10-20 ms | 1-2 ms |

| Durability | Mechanical wear limits lifespan (~100,000 cycles) | Long lifespan (>100 million cycles) |

| Noise | Audible click | Silent operation |

| Power Consumption | Higher coil power required | Low input power consumption |

| Load Type | AC and DC loads | Primarily AC loads; some models support DC |

| Size | Bulkier due to mechanical parts | Compact and lightweight |

| EMI Susceptibility | Higher due to mechanical arcing | Lower electromagnetic interference |

| Cost | Lower initial cost | Higher initial cost |

| Applications | General-purpose switching, high current loads | High-speed switching, sensitive electronics |

Introduction to Electromechanical Relays and Solid-State Relays

Electromechanical relays use physical moving parts like an armature and contacts to open or close circuits, offering electrical isolation and mechanical durability but slower switching speeds. Solid-state relays rely on semiconductor devices such as triacs or transistors to perform switching without moving parts, providing faster operation, longer lifespan, and better resistance to shock and vibration. Both relay types serve critical roles in controlling electrical loads, with electromechanical relays preferred for high current applications and solid-state relays favored for rapid, silent switching.

Working Principle: Electromechanical vs. Solid-State Relays

Electromechanical relays operate using an electromagnetic coil that physically moves contacts to open or close circuits, providing mechanical isolation between the control and load. Solid-state relays rely on semiconductor components such as thyristors or transistors to perform switching without moving parts, enabling faster response times and increased durability. The fundamental difference lies in mechanical movement for electromechanical relays versus electronic switching in solid-state relays, impacting speed, noise, and lifespan.

Key Components and Construction Differences

Electromechanical relays utilize a physical coil, armature, and mechanical contacts to switch circuits, resulting in slower response times and wear over prolonged use. Solid-state relays employ semiconductor devices such as TRIACs or MOSFETs, eliminating moving parts for faster switching and longer longevity. The key construction difference lies in the electromechanical relay's reliance on mechanical motion versus the solid-state relay's electronic switching components.

Switching Speed and Response Time Comparison

Electromechanical relays typically exhibit switching speeds in the range of 5 to 20 milliseconds, making them slower than solid-state relays, which can switch within microseconds to a few milliseconds. The response time of solid-state relays is significantly faster due to the absence of moving parts and reliance on semiconductor components. Consequently, solid-state relays are preferred in applications requiring rapid switching and precise timing control.

Electrical and Mechanical Lifetime

Electromechanical relays typically offer a mechanical lifetime of around 10 million operations and an electrical lifetime ranging from 100,000 to 1 million operations, limited by physical wear and contact erosion. Solid-state relays provide an electrical lifetime exceeding 100 million operations due to the absence of moving parts, while their mechanical lifetime is virtually unlimited. The choice between these relays depends on the application's switching frequency, with solid-state relays being preferred for high-cycle, long-duration usage.

Load Capacity and Suitability

Electromechanical relays typically handle higher load currents up to 30A with robust surge tolerance, making them suitable for heavy-duty industrial applications. Solid-state relays offer faster switching and longer life with load capacities generally limited to 40A, ideal for sensitive electronic devices requiring silent operation. Selection depends on the application's load type, switching frequency, and environmental factors, balancing performance and durability.

Applications in Industrial Environments

Electromechanical relays are commonly used in industrial environments for applications requiring high current switching and electrical isolation, such as motor control and heavy machinery operation, due to their robust physical contacts and ability to handle voltage spikes. Solid-state relays are preferred in precision control systems and environments demanding silent operation, fast switching, and vibration resistance, including automated production lines and temperature control equipment. Selecting between electromechanical and solid-state relays depends on factors like load type, switching speed, electrical noise tolerance, and environmental conditions in industrial applications.

Advantages and Disadvantages of Each Relay Type

Electromechanical relays offer advantages such as high current handling capacity and clear physical isolation between control and load circuits, but they suffer from mechanical wear, slower switching speeds, and audible noise. Solid-state relays provide faster switching, longer lifespan due to lack of moving parts, and silent operation, but are limited by heat dissipation requirements, higher initial cost, and typically lower current ratings. Choosing between the two depends on application demands for durability, speed, current load, and electrical isolation.

Cost Factor and Maintenance Requirements

Electromechanical relays generally have a lower initial cost compared to solid-state relays, making them a budget-friendly option for many applications. However, their mechanical contacts are prone to wear and require periodic maintenance or replacement, increasing long-term operational costs. Solid-state relays, while more expensive upfront, offer maintenance-free operation due to the absence of moving parts, reducing downtime and total cost of ownership in the long run.

Choosing the Right Relay for Your Application

Electromechanical relays offer reliable contact isolation and are ideal for applications requiring high current switching and low-cost solutions. Solid-state relays provide faster switching speeds, longer lifespan, and noise-free operation, making them suitable for sensitive electronics and environments with frequent switching cycles. Matching relay specifications such as load type, switching frequency, and environmental conditions ensures optimal performance and durability in your electrical system.

Related Important Terms

Zero-Cross Switching

Zero-cross switching in electromechanical relays reduces electrical noise and prolongs contact life by closing contacts precisely at the AC waveform's zero voltage point. Solid-state relays inherently perform zero-cross switching using semiconductor components, enabling faster, quieter operation and increased reliability without mechanical wear.

Bounce-Free Operation

Electromechanical relays experience contact bounce, causing multiple undesired electrical pulses during switching, whereas solid-state relays provide bounce-free operation due to their semiconductor-based switching mechanism. This results in faster, noise-free, and more reliable switching performance ideal for high-speed and precision applications.

Mechanical Arc Suppression

Electromechanical relays rely on physical contacts that generate mechanical arcs when switching high currents, necessitating arc suppression techniques like blowout coils or arc chutes to prolong contact life and ensure safety. Solid-state relays eliminate mechanical arcs entirely by using semiconductor switching devices, offering superior durability and faster switching without the need for arc suppression mechanisms.

Load Voltage Isolation

Electromechanical relays provide superior load voltage isolation due to their physical separation of contacts, ensuring minimal electrical noise and interference. Solid-state relays rely on semiconductor components, which offer faster switching but generally provide lower voltage isolation and are more susceptible to leakage currents.

Trigger Voltage

Electromechanical relays typically require a higher trigger voltage of around 5 to 12 volts DC to activate the coil, whereas solid-state relays operate at much lower trigger voltages, often between 3 to 32 volts DC, enabling more efficient and precise control in low-voltage applications. The lower trigger voltage of solid-state relays contributes to faster switching speeds and longer operational lifespan compared to the mechanical wear in electromechanical relays.

Snubber Circuit Integration

Electromechanical relays typically require external snubber circuits to protect contacts from voltage spikes and prevent arcing, enhancing longevity and reliability. Solid-state relays often have built-in snubber circuits or use inherent semiconductor properties, reducing the need for additional components and improving switching performance in high-frequency applications.

Galvanic Isolation

Electromechanical relays provide galvanic isolation through physical separation of contacts, ensuring complete electrical isolation between the input and output circuits. Solid-state relays achieve galvanic isolation using optocouplers or transformers, offering faster switching speeds and improved durability without mechanical wear.

Lifetime Switching Cycles

Electromechanical relays typically offer around 100,000 switching cycles due to mechanical wear and tear, while solid-state relays provide significantly longer lifespans exceeding 10 million switching cycles, thanks to their lack of moving parts. This extended lifetime makes solid-state relays ideal for applications requiring high switching frequency and reliability.

Thermal Management (SSR)

Solid-state relays (SSR) require effective thermal management due to heat dissipation caused by internal semiconductor components during switching, often necessitating heat sinks or cooling systems to maintain optimal operation temperature and prevent thermal runaway. Compared to electromechanical relays, SSRs have no moving parts but generate continuous heat dependent on load current, making thermal design crucial for reliability and longevity in high-power applications.

Coil Power Consumption

Electromechanical relays typically consume higher coil power, often ranging from 200 to 500 milliwatts, due to their mechanical operation requiring magnetic force to actuate contacts. Solid-state relays, on the other hand, have significantly lower coil power consumption, usually below 100 milliwatts, because they use semiconductor components to switch without moving parts.

Electromechanical relay vs solid-state relay Infographic

industrydif.com

industrydif.com