Fossil fuel plants rely on burning coal, oil, or natural gas, resulting in significant greenhouse gas emissions and environmental pollution. Green hydrogen plants produce electricity by using renewable energy to electrolyze water, generating clean hydrogen that emits only water vapor when used. Transitioning to green hydrogen technology reduces carbon footprints and supports sustainable energy goals.

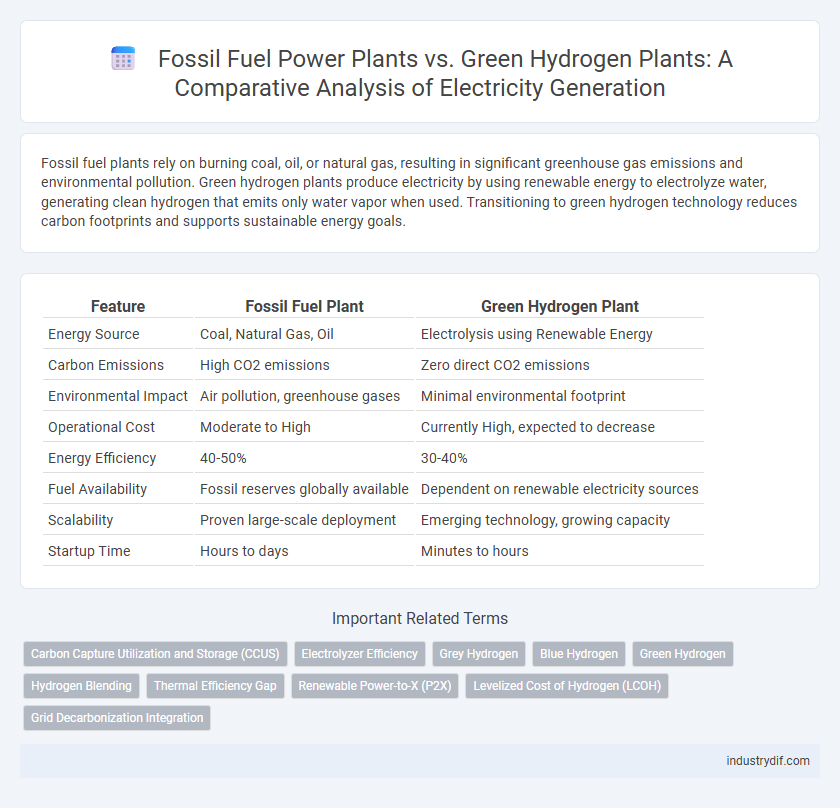

Table of Comparison

| Feature | Fossil Fuel Plant | Green Hydrogen Plant |

|---|---|---|

| Energy Source | Coal, Natural Gas, Oil | Electrolysis using Renewable Energy |

| Carbon Emissions | High CO2 emissions | Zero direct CO2 emissions |

| Environmental Impact | Air pollution, greenhouse gases | Minimal environmental footprint |

| Operational Cost | Moderate to High | Currently High, expected to decrease |

| Energy Efficiency | 40-50% | 30-40% |

| Fuel Availability | Fossil reserves globally available | Dependent on renewable electricity sources |

| Scalability | Proven large-scale deployment | Emerging technology, growing capacity |

| Startup Time | Hours to days | Minutes to hours |

Overview of Fossil Fuel and Green Hydrogen Power Plants

Fossil fuel power plants generate electricity by burning coal, natural gas, or oil, releasing significant carbon dioxide and other greenhouse gases that contribute to climate change. Green hydrogen power plants produce energy by using electrolysis to split water into hydrogen and oxygen, employing renewable sources such as wind or solar power to achieve zero carbon emissions. The shift from fossil fuel plants to green hydrogen technology represents a critical move toward sustainable and clean energy systems worldwide.

Key Differences in Technology and Infrastructure

Fossil fuel plants rely on combustion of coal, oil, or natural gas to generate electricity, utilizing established infrastructure such as boilers, turbines, and extensive emission control systems. Green hydrogen plants produce electricity by electrolyzing water using renewable energy sources, requiring advanced electrolyzers, hydrogen storage tanks, and fuel cells or turbines adapted for hydrogen fuel. The transition from fossil fuel to green hydrogen technology demands significant upgrades in energy storage, safety protocols, and distribution networks to accommodate hydrogen's properties and environmental benefits.

Energy Production Efficiency Comparison

Fossil fuel plants typically achieve energy production efficiencies ranging from 33% to 40%, with combined-cycle gas plants reaching up to 60%, while green hydrogen plants currently operate at lower efficiencies due to energy losses in electrolysis and fuel cell conversion, often around 20% to 25%. The overall efficiency of green hydrogen is impacted by the electrolysis process, which converts electricity into hydrogen with 65%-80% efficiency, and subsequent fuel cell or combustion usage with additional energy conversion losses. Despite lower current efficiencies, green hydrogen plants offer zero carbon emissions, making energy production efficiency comparisons critical for balancing sustainability goals with operational performance.

Environmental Impact and Emissions Analysis

Fossil fuel plants release significant amounts of CO2, NOx, and particulate matter, contributing to air pollution and climate change, whereas green hydrogen plants produce near-zero emissions, relying on renewable energy sources for hydrogen production. The environmental impact of fossil fuel plants includes habitat degradation and water contamination from extraction and combustion processes, while green hydrogen facilities minimize ecological disruption through sustainable water use and clean energy integration. Transitioning to green hydrogen plants reduces greenhouse gas emissions and supports carbon neutrality goals crucial for mitigating global warming effects.

Resource Availability and Supply Chain

Fossil fuel plants rely heavily on finite natural resources like coal, oil, and natural gas, which face extraction challenges and supply chain disruptions due to geopolitical tensions. Green hydrogen plants utilize water and renewable energy sources such as solar and wind, offering a more sustainable and abundant resource base with a decentralized supply chain. The scalability of green hydrogen production is supported by advances in electrolyzer technology and decreasing costs of renewable energy infrastructure.

Cost Structures: Capital and Operational Expenses

Fossil fuel plants typically incur higher operational expenses due to fuel procurement and emissions management, while green hydrogen plants face substantial capital costs linked to electrolyzer technology and renewable energy infrastructure. Capital expenditures for green hydrogen plants are currently elevated but expected to decline with technological advancements and economies of scale, reducing the levelized cost of hydrogen production. Operational costs for green hydrogen plants benefit from zero fuel expenses, making them increasingly competitive as renewable electricity prices fall.

Grid Integration and Reliability Factors

Fossil fuel plants provide stable, dispatchable power that ensures grid reliability through consistent output and fast ramping capabilities. Green hydrogen plants depend on variable renewable energy sources like solar and wind, requiring advanced energy storage and grid management technologies to maintain integration and reliability. The scalability of green hydrogen systems offers potential for grid flexibility but currently faces challenges in matching the continuous power supply characteristic of fossil fuel plants.

Regulatory Landscape and Policy Incentives

Fossil fuel plants face tightening emissions regulations and carbon pricing mechanisms that increase operational costs, while green hydrogen plants benefit from expanding governmental subsidies, tax credits, and mandates supporting clean energy transitions. Policies such as the IRA (Inflation Reduction Act) in the U.S. and the EU's Green Deal prioritize green hydrogen production through funding for infrastructure and research, accelerating market adoption. Regulatory frameworks increasingly mandate decarbonization targets, making green hydrogen plants more competitive due to preferential treatment in permitting and grid integration compared to fossil fuel facilities.

Market Trends and Future Prospects

The fossil fuel plant market remains substantial due to established infrastructure and consistent energy demand, but faces declining investment driven by regulatory pressures and carbon pricing. Green hydrogen plants are rapidly gaining traction, supported by technological advancements, government subsidies, and increasing corporate commitments to decarbonization, positioning them as key players in the transition to sustainable energy. Market forecasts project green hydrogen capacity to expand exponentially by 2030, potentially eclipsing fossil fuel plants in strategic importance within the electricity generation sector.

Challenges and Opportunities for Transition

Fossil fuel plants face challenges including high carbon emissions, regulatory pressure, and aging infrastructure, while green hydrogen plants offer opportunities through zero-emission energy production and integration with renewable resources like solar and wind. Transitioning involves overcoming obstacles such as the high cost of hydrogen production, limited storage and transportation infrastructure, and the need for technological advancements in electrolyzers and fuel cells. Investments in research, policy incentives, and scaling renewable energy capacity are critical to facilitate the shift from fossil fuels to green hydrogen for sustainable electricity generation.

Related Important Terms

Carbon Capture Utilization and Storage (CCUS)

Fossil fuel plants rely heavily on Carbon Capture Utilization and Storage (CCUS) technologies to reduce CO2 emissions by capturing and storing carbon underground, though their effectiveness is limited by the continuous carbon output from combustion. Green hydrogen plants produce zero direct emissions, significantly lowering the need for CCUS while offering a sustainable alternative by utilizing renewable energy for hydrogen generation through electrolysis.

Electrolyzer Efficiency

Electrolyzer efficiency in green hydrogen plants typically ranges between 60-80%, significantly impacting the overall energy conversion compared to fossil fuel plants, where thermal efficiency averages around 33-40%. Higher electrolyzer efficiency enhances green hydrogen production by reducing electricity consumption, making it a critical factor in determining the sustainability and cost-effectiveness of green energy systems versus traditional fossil fuel power generation.

Grey Hydrogen

Grey hydrogen production in fossil fuel plants relies on natural gas reforming, emitting significant carbon dioxide and contributing heavily to greenhouse gas levels compared to green hydrogen plants that utilize renewable energy sources like wind or solar for water electrolysis, resulting in near-zero emissions. The environmental impact and operational costs of grey hydrogen make it less sustainable than green hydrogen, which aligns with global decarbonization goals and cleaner energy transitions.

Blue Hydrogen

Blue hydrogen plants produce hydrogen through natural gas reforming combined with carbon capture and storage (CCS), significantly reducing CO2 emissions compared to traditional fossil fuel plants that rely on direct combustion of coal or natural gas. While fossil fuel plants emit approximately 820 grams of CO2 per kWh, blue hydrogen plants can lower carbon intensity to around 100-200 grams per kWh, enabling a cleaner transition in electricity generation.

Green Hydrogen

Green hydrogen plants produce electricity through electrolysis using renewable energy sources, emitting zero carbon dioxide compared to fossil fuel plants that burn coal or natural gas, releasing significant greenhouse gases. This clean energy technology supports grid decarbonization, reduces air pollution, and enhances energy security by utilizing abundant water and solar or wind power instead of finite fossil fuels.

Hydrogen Blending

Hydrogen blending in fossil fuel plants involves mixing green hydrogen with natural gas to reduce carbon emissions while utilizing existing infrastructure, enhancing fuel flexibility without major retrofits. Green hydrogen plants produce pure hydrogen through electrolysis powered by renewable energy, enabling zero-emission electricity generation but currently facing higher costs and infrastructural challenges compared to hydrogen blending methods.

Thermal Efficiency Gap

Fossil fuel plants typically achieve thermal efficiencies between 33% and 45%, limited by combustion and heat losses, whereas green hydrogen plants, utilizing electrolysis and fuel cells, can surpass these limits by converting renewable energy with efficiencies ranging from 40% to 60%. The thermal efficiency gap underscores the potential for green hydrogen to offer cleaner energy solutions while improving overall energy conversion rates compared to traditional fossil fuel power generation.

Renewable Power-to-X (P2X)

Fossil fuel plants rely heavily on non-renewable resources, emitting significant greenhouse gases, whereas green hydrogen plants utilize renewable power-to-X (P2X) technologies to convert excess renewable electricity into clean hydrogen fuel, enabling carbon-neutral energy storage and usage. This transition to green hydrogen supports grid stability and decarbonizes sectors like industrial processes and heavy transport by leveraging electrolysis powered by solar and wind energy.

Levelized Cost of Hydrogen (LCOH)

Fossil fuel plants typically have lower Levelized Cost of Hydrogen (LCOH) due to established infrastructure and lower initial capital expenses, but they incur higher operational costs and carbon pricing risks compared to green hydrogen plants. Green hydrogen plants, despite higher upfront investment driven by electrolyzer costs and renewable energy integration, benefit from decreasing LCOH trends fueled by advancements in renewable technologies and economies of scale.

Grid Decarbonization Integration

Fossil fuel plants emit significant carbon dioxide, complicating grid decarbonization efforts due to high greenhouse gas outputs, whereas green hydrogen plants produce zero carbon emissions by using renewable energy for electrolysis, enabling seamless integration into a clean energy grid. The scalability of green hydrogen facilitates grid stability and energy storage solutions, addressing intermittent renewable supply challenges more effectively than traditional fossil fuel-based electricity generation.

Fossil Fuel Plant vs Green Hydrogen Plant Infographic

industrydif.com

industrydif.com