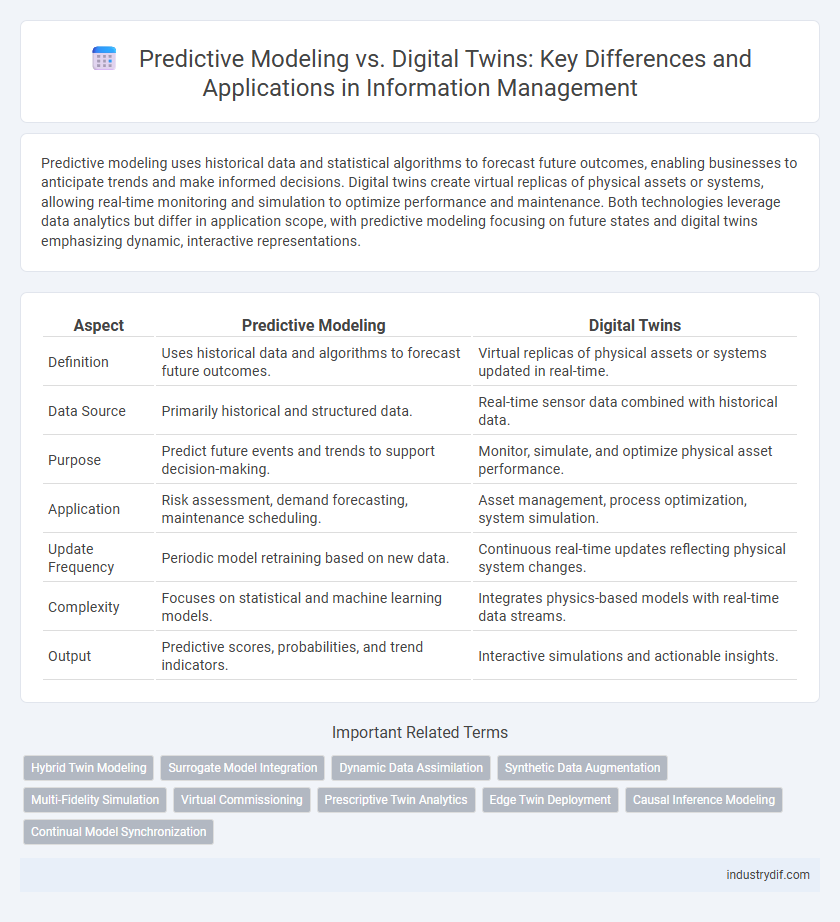

Predictive modeling uses historical data and statistical algorithms to forecast future outcomes, enabling businesses to anticipate trends and make informed decisions. Digital twins create virtual replicas of physical assets or systems, allowing real-time monitoring and simulation to optimize performance and maintenance. Both technologies leverage data analytics but differ in application scope, with predictive modeling focusing on future states and digital twins emphasizing dynamic, interactive representations.

Table of Comparison

| Aspect | Predictive Modeling | Digital Twins |

|---|---|---|

| Definition | Uses historical data and algorithms to forecast future outcomes. | Virtual replicas of physical assets or systems updated in real-time. |

| Data Source | Primarily historical and structured data. | Real-time sensor data combined with historical data. |

| Purpose | Predict future events and trends to support decision-making. | Monitor, simulate, and optimize physical asset performance. |

| Application | Risk assessment, demand forecasting, maintenance scheduling. | Asset management, process optimization, system simulation. |

| Update Frequency | Periodic model retraining based on new data. | Continuous real-time updates reflecting physical system changes. |

| Complexity | Focuses on statistical and machine learning models. | Integrates physics-based models with real-time data streams. |

| Output | Predictive scores, probabilities, and trend indicators. | Interactive simulations and actionable insights. |

Introduction to Predictive Modeling and Digital Twins

Predictive modeling uses historical data and statistical algorithms to forecast future outcomes, enabling proactive decision-making across industries. Digital twins create real-time virtual replicas of physical assets or systems, allowing simulation, monitoring, and optimization of performance. Both technologies leverage data analytics but differ in application: predictive modeling anticipates trends, while digital twins provide dynamic, interactive insights.

Key Definitions and Concepts

Predictive modeling involves using statistical algorithms and machine learning techniques to analyze historical data and forecast future outcomes, enhancing decision-making processes. Digital twins create a dynamic digital replica of physical systems or processes, enabling real-time monitoring and simulation to optimize performance and predict maintenance needs. Both approaches leverage data-driven insights but differ in scope, with predictive modeling focusing on outcome prediction and digital twins emphasizing continuous interaction between virtual models and their physical counterparts.

Core Technologies Behind Each Approach

Predictive modeling leverages statistical algorithms, machine learning, and data mining techniques to analyze historical data and forecast future outcomes. Digital twins utilize IoT sensors, real-time data integration, and simulation software to create dynamic digital replicas of physical systems. Both technologies rely on advanced analytics and cloud computing platforms to enable accurate decision-making and operational optimization.

Data Requirements: Predictive Models vs Digital Twins

Predictive models primarily rely on historical and real-time data to forecast future events or behaviors, requiring extensive datasets for training and validation. Digital twins demand comprehensive, real-time data streams combined with physical, operational, and environmental data to create an accurate virtual replica of physical assets or systems. The data integration intensity and granularity in digital twins surpass predictive models, enabling dynamic simulation and continuous updates.

Application Areas and Use Cases

Predictive modeling is widely applied in finance for credit scoring and fraud detection, while digital twins excel in manufacturing by simulating physical assets for real-time monitoring and maintenance. In healthcare, predictive models forecast patient outcomes, whereas digital twins create virtual replicas of organs to personalize treatment. Both technologies enhance decision-making, with predictive modeling emphasizing future trends and digital twins providing dynamic, interactive simulations.

Model Accuracy and Real-Time Capabilities

Predictive modeling relies on historical data to forecast outcomes with a focus on accuracy through statistical algorithms, whereas digital twins integrate real-time sensor data to continuously update their models for precise simulation. Digital twins excel in real-time capabilities, enabling immediate adjustments and monitoring that enhance operational efficiency and decision-making. Model accuracy in predictive modeling depends on data quality and algorithm sophistication, while digital twins achieve higher fidelity by mirroring physical systems instantaneously.

Scalability and Integration Considerations

Predictive modeling offers scalability through adaptable algorithms that can process large datasets and update forecasts in real time, enabling integration with diverse data sources and enterprise systems. Digital twins require robust infrastructure and standardized protocols to synchronize virtual replicas with physical assets continuously, posing challenges for seamless integration across complex environments. Both approaches demand careful evaluation of system compatibility and data interoperability to ensure scalable deployment and effective cross-platform communication.

Benefits and Limitations Comparison

Predictive modeling offers significant benefits in forecasting future outcomes based on historical data, enabling proactive decision-making and risk management across industries such as finance and healthcare. Digital twins provide dynamic, real-time simulations of physical assets or systems, enhancing operational efficiencies and enabling predictive maintenance by integrating IoT sensor data and AI analytics. However, predictive models may struggle with accuracy if underlying data is incomplete or biased, while digital twins require substantial upfront investment in technology infrastructure and continuous data integration to remain effective.

Industry Adoption Trends

Industry adoption trends reveal that predictive modeling remains more widely implemented across manufacturing and supply chain sectors due to its cost-effectiveness and faster deployment. Digital twins are gaining traction in aerospace, automotive, and smart cities, driven by their ability to provide real-time simulations and enhance operational efficiency. Market analysis shows an increasing investment in hybrid approaches combining predictive models with digital twin technology to maximize predictive accuracy and dynamic system monitoring.

Future Outlook: Predictive Modeling and Digital Twins

Predictive modeling leverages historical data and machine learning algorithms to forecast future trends, driving proactive decision-making across industries. Digital twins create dynamic virtual replicas of physical assets, enabling real-time simulation and optimization for enhanced operational efficiency. Future developments will likely see increased integration of AI and IoT technologies, expanding predictive accuracy and the application scope of digital twins in smart cities, manufacturing, and healthcare.

Related Important Terms

Hybrid Twin Modeling

Hybrid Twin Modeling integrates predictive modeling's statistical algorithms with digital twins' real-time simulations to enhance accuracy and adaptability in forecasting system behaviors. This approach enables dynamic updates using live data streams, providing comprehensive insights for proactive decision-making across industries such as manufacturing, healthcare, and smart cities.

Surrogate Model Integration

Surrogate model integration in predictive modeling enhances computational efficiency by approximating complex system behaviors, enabling faster simulations and real-time decision-making. Digital twins leverage these surrogate models to replicate physical assets accurately, facilitating continuous monitoring and predictive maintenance through high-fidelity virtual representations.

Dynamic Data Assimilation

Predictive modeling utilizes historical and real-time data to forecast future outcomes by identifying patterns and trends, while digital twins create a dynamic virtual replica of physical systems incorporating continuous real-time data streams. Dynamic data assimilation enhances digital twins by integrating live sensor data for real-time system monitoring and adaptive decision-making, surpassing traditional predictive models in accuracy and responsiveness.

Synthetic Data Augmentation

Predictive modeling leverages historical data patterns to forecast future outcomes, while digital twins create real-time virtual replicas of physical systems for dynamic simulation. Synthetic data augmentation enhances both approaches by generating realistic, diverse datasets that improve model accuracy and robustness without relying solely on real-world data.

Multi-Fidelity Simulation

Multi-fidelity simulation enhances predictive modeling and digital twins by integrating high- and low-fidelity data to balance accuracy and computational cost. This approach enables more efficient scenario analysis and decision-making in complex systems, improving the precision of digital twin environments and predictive forecasts.

Virtual Commissioning

Virtual commissioning leverages digital twins to create accurate, real-time representations of physical systems, enabling thorough testing and optimization before actual deployment. Predictive modeling complements this process by analyzing historical data to forecast system performance and identify potential faults, enhancing decision-making during virtual commissioning.

Prescriptive Twin Analytics

Prescriptive Twin Analytics integrates predictive modeling with digital twins to not only forecast future outcomes but also recommend optimal actions based on real-time simulation data. This advanced approach enhances decision-making accuracy in industries such as manufacturing, healthcare, and smart cities by enabling proactive interventions and operational efficiency.

Edge Twin Deployment

Edge twin deployment enhances predictive modeling by enabling real-time data processing and simulation directly on distributed IoT devices, reducing latency and bandwidth usage. This approach improves decision-making accuracy and operational efficiency in industries like manufacturing, energy, and smart cities by providing localized and dynamic insights.

Causal Inference Modeling

Predictive modeling leverages historical data to forecast outcomes by identifying correlations, while digital twins create dynamic virtual replicas of physical systems for real-time monitoring and simulation. Causal inference modeling enhances these approaches by uncovering cause-and-effect relationships, enabling more accurate predictions and optimized decision-making within both predictive models and digital twin frameworks.

Continual Model Synchronization

Predictive modeling relies on historical data to forecast future outcomes, while digital twins continuously synchronize real-time data from physical assets to provide dynamic, up-to-date simulations. This continual model synchronization in digital twins ensures more accurate operational insights and adaptive decision-making compared to static predictive models.

Predictive Modeling vs Digital Twins Infographic

industrydif.com

industrydif.com