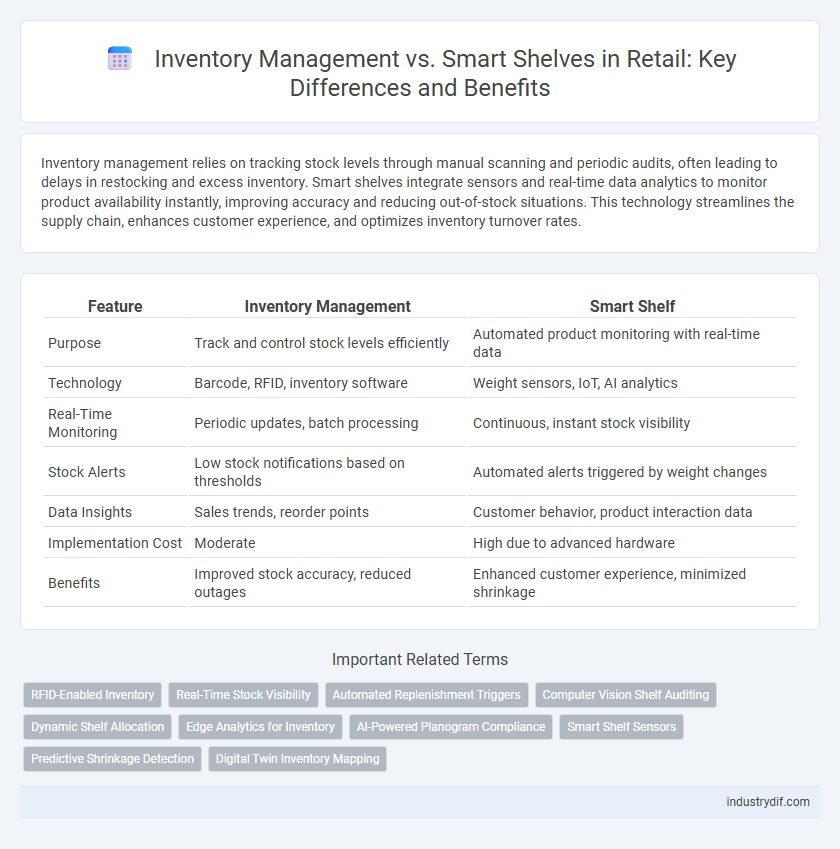

Inventory management relies on tracking stock levels through manual scanning and periodic audits, often leading to delays in restocking and excess inventory. Smart shelves integrate sensors and real-time data analytics to monitor product availability instantly, improving accuracy and reducing out-of-stock situations. This technology streamlines the supply chain, enhances customer experience, and optimizes inventory turnover rates.

Table of Comparison

| Feature | Inventory Management | Smart Shelf |

|---|---|---|

| Purpose | Track and control stock levels efficiently | Automated product monitoring with real-time data |

| Technology | Barcode, RFID, inventory software | Weight sensors, IoT, AI analytics |

| Real-Time Monitoring | Periodic updates, batch processing | Continuous, instant stock visibility |

| Stock Alerts | Low stock notifications based on thresholds | Automated alerts triggered by weight changes |

| Data Insights | Sales trends, reorder points | Customer behavior, product interaction data |

| Implementation Cost | Moderate | High due to advanced hardware |

| Benefits | Improved stock accuracy, reduced outages | Enhanced customer experience, minimized shrinkage |

Overview of Inventory Management in Retail

Inventory management in retail involves tracking and controlling stock levels to ensure product availability while minimizing carrying costs and stockouts. Traditional methods rely on manual counts and periodic audits, whereas smart shelves integrate sensors and IoT technology to provide real-time inventory data and automatic replenishment alerts. Effective inventory management optimizes supply chain efficiency, reduces waste, and enhances customer satisfaction through accurate stock visibility and timely restocking.

Defining Smart Shelf Technology

Smart shelf technology integrates RFID sensors and weight sensors to provide real-time inventory tracking and automatic stock level updates, enhancing accuracy compared to traditional inventory management methods. This innovative system reduces human error and labor costs by automating restocking alerts and sales data collection directly from the shelf. Retailers leverage smart shelves to optimize supply chain efficiency, improve product availability, and elevate the customer shopping experience through precise inventory insights.

Key Features of Traditional Inventory Management

Traditional inventory management relies on manual tracking systems, barcode scanning, and periodic stock audits to maintain accurate product counts. Key features include stock level monitoring, reorder point calculations, and supplier order management to prevent stockouts and overstocking. While effective for basic needs, these methods often lack real-time data integration and predictive analytics found in advanced solutions like smart shelves.

Core Benefits of Smart Shelf Solutions

Smart shelf solutions enhance inventory management by providing real-time product tracking through embedded sensors and RFID technology, reducing stockouts and overstock situations. These systems improve accuracy in inventory data, enabling retailers to optimize shelf space and ensure timely replenishment. Enhanced customer experience results from immediate product availability and personalized promotions triggered by smart shelf interactions.

Inventory Accuracy: Manual vs Automated Approaches

Inventory accuracy in retail is significantly enhanced by automated smart shelf technology, which utilizes weight sensors and RFID tags to provide real-time stock data, reducing human errors common in manual inventory management. Manual approaches often suffer from discrepancies due to infrequent counting and human oversight, resulting in stockouts or overstock situations that impact sales and customer satisfaction. Smart shelves enable precise, continuous inventory tracking, improving replenishment speed and operational efficiency compared to traditional manual methods.

Real-Time Data Insights: Smart Shelf vs Conventional Systems

Smart shelves provide real-time data insights by continuously monitoring inventory levels through embedded sensors and RFID technology, enabling instant updates and accurate stock tracking. Conventional inventory management systems rely on periodic manual counts or barcode scans, leading to delays and potential discrepancies in stock data. The integration of smart shelves significantly enhances inventory accuracy, reduces out-of-stock situations, and optimizes replenishment processes through timely data analytics.

Cost Implications and ROI Comparison

Effective inventory management reduces carrying costs by optimizing stock levels, minimizing overstock and stockouts that directly impact cash flow. Smart shelf technology, integrating real-time data and automated restocking alerts, enhances accuracy and labor efficiency but requires higher initial investment and maintenance expenses. ROI for traditional inventory systems is generally steadier with lower upfront costs, while smart shelves offer accelerated returns through improved sales and reduced shrinkage when deployed in high-traffic retail environments.

Impact on Store Operations and Staff Efficiency

Inventory management provides real-time stock visibility and automated replenishment alerts, significantly reducing out-of-stock situations and manual counting errors in retail stores. Smart shelves enhance operational efficiency by using sensors and RFID technology to track product movement instantly, enabling staff to focus more on customer service rather than routine inventory checks. Together, these technologies streamline store operations, minimize labor costs, and improve overall staff productivity.

Challenges in Implementing Smart Shelf Technology

Implementing smart shelf technology in retail faces challenges such as high initial costs, integration complexities with existing inventory management systems, and data accuracy issues due to sensor limitations. Retailers must also address cybersecurity risks and ensure seamless real-time inventory tracking to prevent stockouts or overstocking. Training staff to effectively use and maintain smart shelves remains a critical hurdle in maximizing technology benefits.

Future Trends: Integrating AI in Retail Inventory Management

AI integration in retail inventory management is revolutionizing stock accuracy and demand forecasting through real-time data analytics and machine learning algorithms. Smart shelves equipped with AI sensors automatically detect product levels, reducing out-of-stock incidents and enabling dynamic pricing strategies. Future trends emphasize seamless connectivity between AI-driven inventory systems and smart shelves, enhancing operational efficiency and customer experience in retail environments.

Related Important Terms

RFID-Enabled Inventory

RFID-enabled inventory management revolutionizes retail by providing real-time tracking and automated stock replenishment, reducing human error and out-of-stock scenarios. Smart shelves equipped with RFID sensors not only monitor product levels but also enhance customer experience by integrating data analytics for optimized shelf placement and personalized promotions.

Real-Time Stock Visibility

Real-time stock visibility in inventory management enables accurate tracking of product availability, reducing stockouts and overstocks through immediate data updates. Smart shelves utilize embedded sensors and IoT technology to provide continuous monitoring and automated alerts, enhancing accuracy and operational efficiency in retail environments.

Automated Replenishment Triggers

Automated replenishment triggers in inventory management use real-time data analytics to predict stock shortages and initiate orders without manual intervention, reducing downtime and stockouts. Smart shelves enhance this process by integrating IoT sensors that monitor product levels and instantly alert systems to reorder, ensuring optimal inventory levels and improving overall retail efficiency.

Computer Vision Shelf Auditing

Inventory management integrates computer vision to automate shelf auditing, enhancing real-time stock accuracy and reducing out-of-stock scenarios. Smart shelves equipped with advanced sensors and AI analyze product placement and customer interaction, optimizing inventory levels and enabling predictive replenishment.

Dynamic Shelf Allocation

Dynamic shelf allocation enhances inventory management by using real-time data and IoT sensors to optimize product placement and stock levels on smart shelves. This approach reduces out-of-stock incidents and increases sales by ensuring the most relevant products are prominently displayed based on consumer behavior and demand analytics.

Edge Analytics for Inventory

Edge analytics in inventory management enables real-time data processing at the point of sale or stock, reducing latency and improving accuracy in stock level monitoring. Smart shelves equipped with edge computing analyze sensor data locally to automate inventory tracking, minimize stockouts, and optimize replenishment cycles for retail efficiency.

AI-Powered Planogram Compliance

AI-powered planogram compliance enhances inventory management by automatically identifying stock discrepancies and optimizing product placement on smart shelves, improving shelf availability and customer experience. Integrating AI-driven analytics with smart shelf technology ensures real-time tracking and compliance with merchandising standards, reducing out-of-stock scenarios and boosting retail operational efficiency.

Smart Shelf Sensors

Smart Shelf Sensors leverage real-time data collection through weight sensors and RFID technology to automatically track inventory levels, reducing stockouts and overstocks with high accuracy. These devices enhance inventory management by enabling instant product detection and seamless integration with retail management systems for optimized shelf replenishment.

Predictive Shrinkage Detection

Inventory management systems provide foundational tracking and stock level optimization, while smart shelf technology leverages IoT sensors and AI analytics for real-time monitoring and predictive shrinkage detection. By analyzing foot traffic patterns and product interactions, smart shelves enable retailers to proactively identify and prevent theft or loss, reducing shrinkage rates significantly compared to traditional inventory controls.

Digital Twin Inventory Mapping

Digital Twin Inventory Mapping revolutionizes traditional inventory management by creating a real-time, virtual replica of physical stock, enabling precise tracking and efficient replenishment. Smart Shelves integrated with this technology enhance accuracy by automatically updating inventory levels and reducing stockouts, thereby optimizing retail operations and customer satisfaction.

Inventory Management vs Smart Shelf Infographic

industrydif.com

industrydif.com