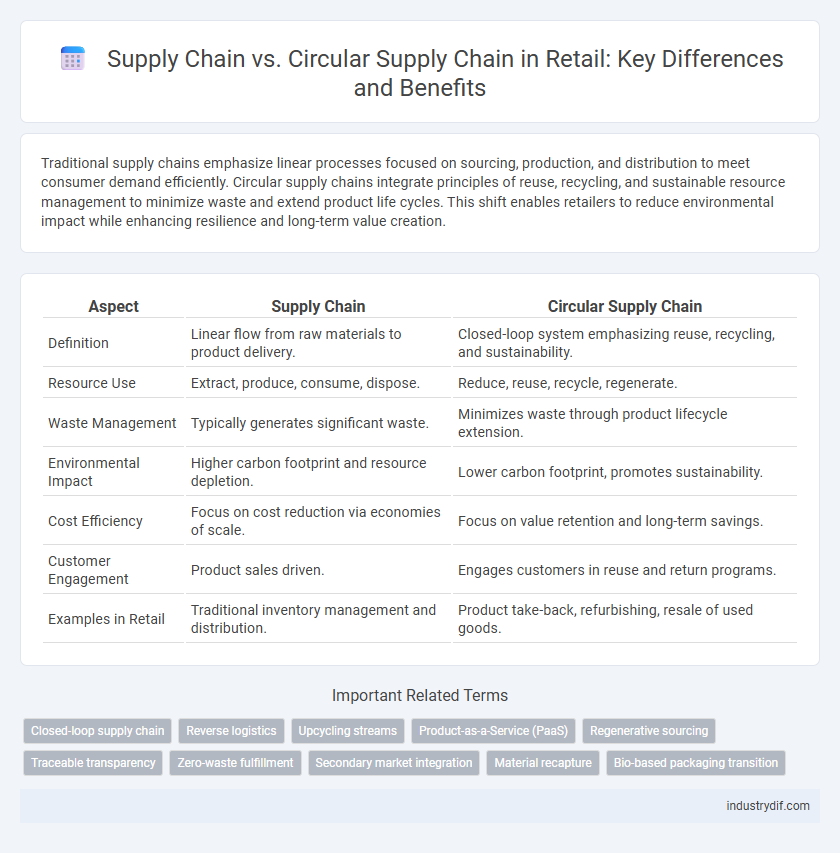

Traditional supply chains emphasize linear processes focused on sourcing, production, and distribution to meet consumer demand efficiently. Circular supply chains integrate principles of reuse, recycling, and sustainable resource management to minimize waste and extend product life cycles. This shift enables retailers to reduce environmental impact while enhancing resilience and long-term value creation.

Table of Comparison

| Aspect | Supply Chain | Circular Supply Chain |

|---|---|---|

| Definition | Linear flow from raw materials to product delivery. | Closed-loop system emphasizing reuse, recycling, and sustainability. |

| Resource Use | Extract, produce, consume, dispose. | Reduce, reuse, recycle, regenerate. |

| Waste Management | Typically generates significant waste. | Minimizes waste through product lifecycle extension. |

| Environmental Impact | Higher carbon footprint and resource depletion. | Lower carbon footprint, promotes sustainability. |

| Cost Efficiency | Focus on cost reduction via economies of scale. | Focus on value retention and long-term savings. |

| Customer Engagement | Product sales driven. | Engages customers in reuse and return programs. |

| Examples in Retail | Traditional inventory management and distribution. | Product take-back, refurbishing, resale of used goods. |

Understanding the Traditional Retail Supply Chain

The traditional retail supply chain involves linear processes where products move from manufacturers to distributors, retailers, and finally to consumers, often leading to excess waste and inefficiencies. Inventory management, demand forecasting, and logistics coordination are critical for minimizing costs and meeting customer expectations in this model. Understanding these linear flows highlights the need for innovative approaches like circular supply chains that incorporate reuse and recycling to enhance sustainability.

Key Components of the Circular Supply Chain in Retail

Key components of the circular supply chain in retail include closed-loop systems that prioritize product lifecycle extension through reuse, refurbishing, and recycling. Advanced inventory management leverages data analytics to optimize resource allocation and minimize waste, while reverse logistics facilitates the efficient return and reintegration of products. Collaboration between suppliers, manufacturers, and retailers ensures sustainable sourcing, enhancing product traceability and reducing environmental impact.

Linear vs. Circular Supply Chain Models: Core Differences

Linear supply chain models follow a one-way flow where raw materials are transformed into products and eventually disposed of as waste, leading to resource depletion and environmental impact. Circular supply chain models prioritize resource recovery, reuse, and recycling, creating a closed-loop system that minimizes waste and maximizes sustainability. Core differences include the shift from linear consumption to continuous material circulation, fostering economic and environmental resilience in retail operations.

Environmental Impact: Supply Chain vs. Circular Supply Chain

Traditional supply chains often generate significant environmental impact through resource depletion, waste, and greenhouse gas emissions, driven by linear production and consumption models. Circular supply chains minimize these effects by emphasizing resource reuse, recycling, and closed-loop processes, significantly reducing landfill waste and carbon footprints. Retailers adopting circular supply chains improve sustainability metrics by lowering raw material extraction and supporting product life extension strategies.

Cost Implications in Retail Supply Chain Approaches

Traditional retail supply chains often incur high costs due to linear processes involving raw material extraction, production, distribution, and disposal, leading to inefficiencies and waste management expenses. Circular supply chains reduce operational costs by implementing resource recovery, recycling, and product reuse strategies, which lower raw material procurement and waste treatment costs. Adopting circular supply chain models enhances cost efficiency while promoting sustainability in retail operations by minimizing environmental impact and optimizing resource utilization.

The Role of Technology in Circular Supply Chains

Technology drives efficiency and transparency in circular supply chains by enabling real-time tracking, resource optimization, and waste reduction through advanced data analytics and IoT sensors. Blockchain enhances traceability and trust by securely recording product lifecycle information, facilitating material recovery and reuse. Automation and AI support predictive maintenance and reverse logistics, minimizing environmental impact while maximizing supply chain resilience.

Sustainable Sourcing and Resource Efficiency

Supply chain management in retail emphasizes sustainable sourcing by prioritizing ethically produced materials and reducing environmental impact through supplier transparency. Circular supply chains enhance resource efficiency by integrating product life extension, recycling, and waste minimization strategies, enabling retailers to close the loop on materials. This approach reduces raw material dependency and fosters long-term sustainability and cost savings.

Consumer Expectations Driving Circular Supply Chains

Consumer expectations for sustainable and ethically sourced products are intensifying, pushing retailers to adopt circular supply chains that emphasize resource reuse and waste reduction. Circular supply chains promote transparency, product longevity, and end-of-life recycling, aligning with consumer demands for environmental responsibility. This paradigm shift enhances brand loyalty and meets regulatory pressures, differentiating retailers in a competitive market.

Challenges and Barriers to Circular Adoption in Retail

Retail supply chains face significant challenges in transitioning to circular supply chains, including high upfront investment costs, complex reverse logistics, and lack of standardized recycling infrastructure. Limited consumer awareness and engagement further hinder the adoption of circular practices, while regulatory uncertainties create operational risks for retailers. Additionally, data fragmentation and inadequate collaboration across suppliers and partners slow down the integration of closed-loop systems essential for circularity.

Future Trends: Evolving Retail Supply Chain Strategies

Future trends in retail supply chain strategies emphasize the shift from traditional linear supply chains to circular supply chains, promoting sustainability and resource efficiency. Circular supply chains incorporate product lifecycle management, reverse logistics, and waste reduction, enabling retailers to minimize environmental impact while meeting consumer demand for eco-friendly practices. Advanced technologies like AI and blockchain support transparency and optimization, driving the evolution of resilient, closed-loop retail supply systems.

Related Important Terms

Closed-loop supply chain

A closed-loop supply chain integrates reverse logistics with traditional supply processes to maximize resource efficiency by recovering, refurbishing, and recycling products. This circular supply chain model reduces waste and lowers costs while enhancing sustainability in retail operations.

Reverse logistics

Supply chain management traditionally focuses on the forward flow of goods from supplier to customer, whereas circular supply chain integrates reverse logistics to recover value through product returns, recycling, and refurbishment processes. Reverse logistics plays a critical role in circular supply chains by enabling efficient handling of returned products, reducing waste, and promoting sustainability in retail operations.

Upcycling streams

Traditional retail supply chains prioritize linear processes designed for product distribution and disposal, often generating significant waste. Circular supply chains incorporate upcycling streams that transform waste materials into valuable products, enhancing sustainability and reducing environmental impact while creating new revenue opportunities.

Product-as-a-Service (PaaS)

Traditional supply chains focus on linear product flow from manufacturer to consumer, while circular supply chains emphasize resource regeneration and product reuse. Product-as-a-Service (PaaS) models drive circular supply chains by enabling companies to retain ownership, optimize asset utilization, and facilitate product lifecycle extension through leasing, subscription, or pay-per-use schemes.

Regenerative sourcing

Regenerative sourcing in circular supply chains emphasizes replenishing natural resources and restoring ecosystems, contrasting with traditional supply chains that often prioritize linear resource extraction. This approach supports sustainable retail by enhancing resource efficiency, reducing waste, and promoting long-term environmental resilience.

Traceable transparency

Traditional supply chains often lack full traceable transparency, leading to inefficiencies and limited accountability. Circular supply chains prioritize traceable transparency through continuous monitoring and data sharing, enabling sustainable resource management and reducing environmental impact in retail operations.

Zero-waste fulfillment

Traditional supply chains prioritize efficiency and cost reduction, often generating significant waste through excess inventory and packaging. Circular supply chains emphasize zero-waste fulfillment by integrating reuse, recycling, and regenerative processes that minimize environmental impact and promote sustainable resource management in retail operations.

Secondary market integration

Integrating the secondary market into traditional supply chains enhances retail efficiency by promoting product life extension, reducing waste, and optimizing resource use through refurbishment and resale. Circular supply chain models prioritize this integration, enabling retailers to capture value from returned, refurbished, or remanufactured goods, thereby supporting sustainability goals and cost savings.

Material recapture

Material recapture in traditional supply chains emphasizes end-of-life product disposal, leading to resource waste and higher costs. Circular supply chains optimize material recapture by integrating reuse, refurbishment, and recycling processes, significantly reducing raw material extraction and enhancing sustainability within retail operations.

Bio-based packaging transition

Transitioning to bio-based packaging in retail supply chains reduces reliance on virgin plastics and decreases carbon emissions, aligning with sustainable procurement goals. Circular supply chains further enhance resource efficiency by enabling packaging reuse, recycling, and biodegradability, driving cost savings and minimizing waste in retail operations.

Supply chain vs Circular supply chain Infographic

industrydif.com

industrydif.com