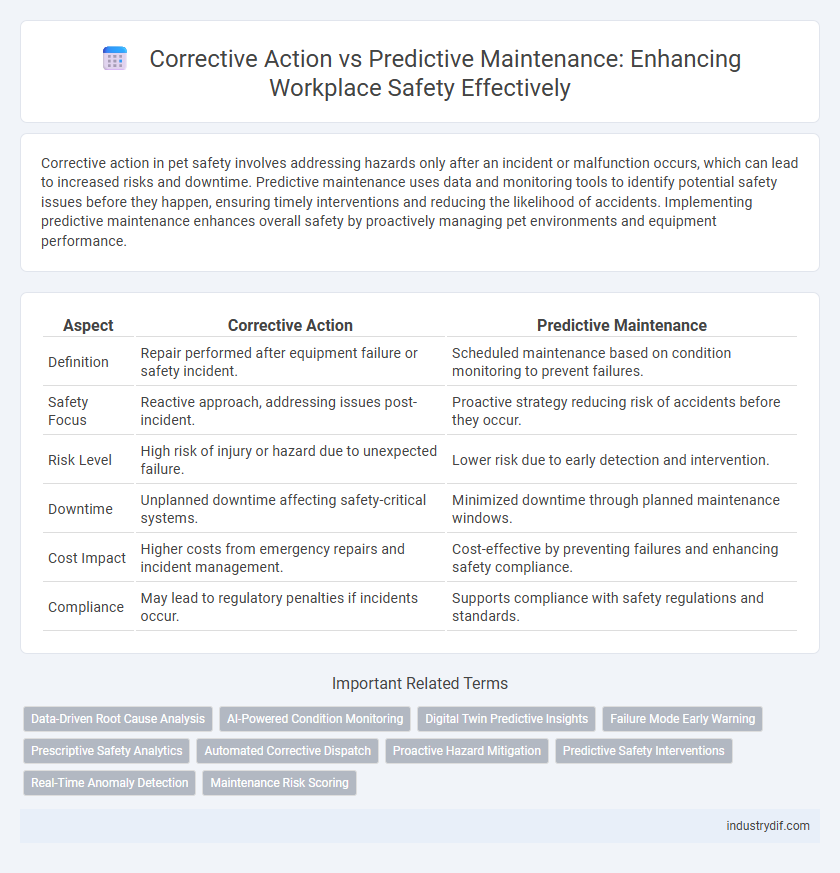

Corrective action in pet safety involves addressing hazards only after an incident or malfunction occurs, which can lead to increased risks and downtime. Predictive maintenance uses data and monitoring tools to identify potential safety issues before they happen, ensuring timely interventions and reducing the likelihood of accidents. Implementing predictive maintenance enhances overall safety by proactively managing pet environments and equipment performance.

Table of Comparison

| Aspect | Corrective Action | Predictive Maintenance |

|---|---|---|

| Definition | Repair performed after equipment failure or safety incident. | Scheduled maintenance based on condition monitoring to prevent failures. |

| Safety Focus | Reactive approach, addressing issues post-incident. | Proactive strategy reducing risk of accidents before they occur. |

| Risk Level | High risk of injury or hazard due to unexpected failure. | Lower risk due to early detection and intervention. |

| Downtime | Unplanned downtime affecting safety-critical systems. | Minimized downtime through planned maintenance windows. |

| Cost Impact | Higher costs from emergency repairs and incident management. | Cost-effective by preventing failures and enhancing safety compliance. |

| Compliance | May lead to regulatory penalties if incidents occur. | Supports compliance with safety regulations and standards. |

Defining Corrective Action in Safety Management

Corrective action in safety management refers to immediate measures taken to fix identified hazards or incidents to prevent recurrence and ensure workplace safety. It involves investigating the root causes of safety failures and implementing targeted solutions such as equipment repairs or procedural changes. This approach contrasts with predictive maintenance, which anticipates and addresses potential safety issues before they cause harm.

What is Predictive Maintenance?

Predictive maintenance uses data analytics and real-time sensor monitoring to anticipate equipment failures before they occur, minimizing unplanned downtime and enhancing workplace safety. Unlike corrective action, which responds to safety incidents or equipment breakdowns after they happen, predictive maintenance proactively identifies potential hazards and performance issues. This approach leverages machine learning algorithms and IoT technology to ensure machinery operates safely and efficiently, reducing the risk of accidents and costly repairs.

Key Differences Between Corrective Action and Predictive Maintenance

Corrective action addresses safety issues after a failure or hazard is detected, focusing on immediate repair and containment to prevent accidents. Predictive maintenance uses data-driven techniques like sensor monitoring and condition analysis to anticipate potential safety risks before they occur, enabling proactive interventions. The key difference lies in timing: corrective action is reactive, triggered by existing problems, while predictive maintenance is proactive, aiming to prevent failures and ensure continuous safety compliance.

The Role of Corrective Action in Incident Prevention

Corrective action plays a crucial role in incident prevention by addressing safety hazards immediately after identification, reducing the risk of recurring incidents. Implementing corrective measures ensures compliance with safety regulations and mitigates root causes of accidents, enhancing overall workplace safety. This proactive response complements predictive maintenance by resolving unexpected failures and preventing safety breaches effectively.

Predictive Maintenance: Reducing Equipment Failures

Predictive maintenance leverages real-time data and advanced analytics to identify equipment anomalies before failures occur, significantly enhancing safety by preventing unexpected breakdowns. This proactive approach minimizes downtime and reduces the risk of accidents caused by equipment malfunctions, outperforming corrective action strategies that respond only after failures. Implementing predictive maintenance systems improves operational reliability and ensures a safer working environment by addressing issues early.

Safety Implications of Reactive vs Proactive Approaches

Corrective action in safety management addresses hazards only after incidents occur, often leading to increased downtime and higher risk of injury. Predictive maintenance employs data-driven monitoring to anticipate and prevent equipment failures, significantly reducing safety risks and unplanned incidents. Proactive approaches enhance workplace safety by identifying potential dangers before they cause harm, whereas reactive methods may result in more severe consequences due to delayed responses.

Data-Driven Decision Making in Predictive Maintenance

Corrective action addresses safety issues after failures occur, leading to increased downtime and potential hazards. Predictive maintenance leverages real-time data analytics and sensor monitoring to forecast equipment failures before they happen, drastically reducing safety risks. Data-driven decision making enhances predictive maintenance by optimizing inspection schedules and resource allocation, ensuring proactive interventions that improve overall workplace safety.

Integrating Corrective Actions Into Safety Programs

Integrating corrective actions into safety programs enhances risk mitigation by addressing hazards identified through incident analysis, ensuring that root causes are systematically eliminated. Corrective action plans complement predictive maintenance by providing reactive solutions that improve equipment reliability and worker safety after failures occur. Embedding these actions within safety management systems promotes continuous improvement and regulatory compliance, reducing workplace accidents effectively.

Cost-Benefit Analysis: Corrective vs Predictive Strategies

Corrective action involves repairing equipment after a failure, often leading to higher downtime costs and safety risks, whereas predictive maintenance uses data-driven techniques to anticipate and prevent failures, reducing unexpected incidents and associated expenses. The cost-benefit analysis favors predictive strategies through lower repair costs, enhanced operational safety, and extended equipment life. Investing in predictive maintenance technology proves economically advantageous by minimizing emergency repairs and improving workplace safety compliance.

Best Practices for Enhancing Safety Through Maintenance Choices

Implementing predictive maintenance significantly enhances safety by anticipating equipment failures before they occur, reducing the risk of accidents caused by unexpected breakdowns. Corrective action, while necessary for addressing immediate hazards, often leads to downtime and increased exposure to unsafe conditions during repair. Best practices involve integrating predictive analytics, condition monitoring, and real-time data to shift from reactive corrective measures to proactive maintenance strategies that ensure continuous safety and reliability.

Related Important Terms

Data-Driven Root Cause Analysis

Data-driven root cause analysis in corrective action leverages past incident data to identify underlying hazards and implement targeted safety improvements, reducing the recurrence of failures. Predictive maintenance uses real-time sensor data and analytics to anticipate equipment failures before they occur, enhancing workplace safety by preventing accidents proactively.

AI-Powered Condition Monitoring

AI-powered condition monitoring enhances predictive maintenance by continuously analyzing real-time sensor data to identify early signs of equipment failure, reducing safety risks before they manifest. Corrective action, triggered only after faults occur, lacks this proactive detection, making AI-driven predictive maintenance essential for optimizing workplace safety and minimizing unexpected downtime.

Digital Twin Predictive Insights

Corrective action addresses safety issues after failures occur, often leading to unexpected downtime and increased risk, whereas predictive maintenance leverages Digital Twin predictive insights to identify potential hazards and equipment degradation before they impact operations. Digital Twin technology simulates real-time asset conditions, enabling proactive safety measures and reducing accident rates through continuous monitoring and data-driven decision-making.

Failure Mode Early Warning

Corrective action addresses safety issues after failure occurs, leading to downtime and potential hazards, whereas predictive maintenance leverages failure mode early warning systems to detect anomalies and prevent incidents before they escalate. Implementing predictive maintenance significantly enhances workplace safety by enabling timely interventions based on real-time data analysis, reducing the risk of unexpected equipment failures.

Prescriptive Safety Analytics

Prescriptive safety analytics integrates real-time data and machine learning algorithms to recommend precise corrective actions before safety incidents occur, enhancing predictive maintenance strategies by identifying potential hazards and optimizing resource allocation. This approach reduces downtime and mitigates risks more effectively than reactive corrective action, ensuring a safer work environment through proactive intervention.

Automated Corrective Dispatch

Automated Corrective Dispatch enhances safety by promptly addressing detected hazards through immediate corrective actions, reducing the likelihood of accidents caused by equipment failures. Predictive Maintenance minimizes safety risks by forecasting potential failures in advance, but Automated Corrective Dispatch ensures faster response times to unforeseen safety issues, improving overall hazard mitigation.

Proactive Hazard Mitigation

Predictive maintenance enhances safety by identifying potential equipment failures before they occur, enabling proactive hazard mitigation that reduces workplace accidents and downtime. Corrective action responds to incidents after they happen, often leading to increased risks and costs, whereas predictive maintenance prioritizes early detection and prevention for safer operational environments.

Predictive Safety Interventions

Predictive safety interventions leverage advanced data analytics and real-time monitoring to anticipate equipment failures and hazardous conditions before they occur, significantly reducing downtime and preventing accidents. Unlike corrective action, which responds reactively to incidents, predictive maintenance proactively enhances workplace safety by identifying risks early and optimizing preventive measures.

Real-Time Anomaly Detection

Real-time anomaly detection enhances safety by enabling predictive maintenance to identify potential equipment failures before they occur, reducing downtime and preventing accidents. Corrective action responds after anomalies are detected, but predictive maintenance leverages continuous data monitoring for proactive risk mitigation and improved operational safety.

Maintenance Risk Scoring

Maintenance risk scoring enhances safety by prioritizing predictive maintenance over corrective action, enabling early identification of potential failures and reducing unexpected downtime. Implementing predictive maintenance supported by risk scoring minimizes hazards and operational risks by addressing equipment issues before they escalate into safety incidents.

Corrective Action vs Predictive Maintenance for Safety Infographic

industrydif.com

industrydif.com