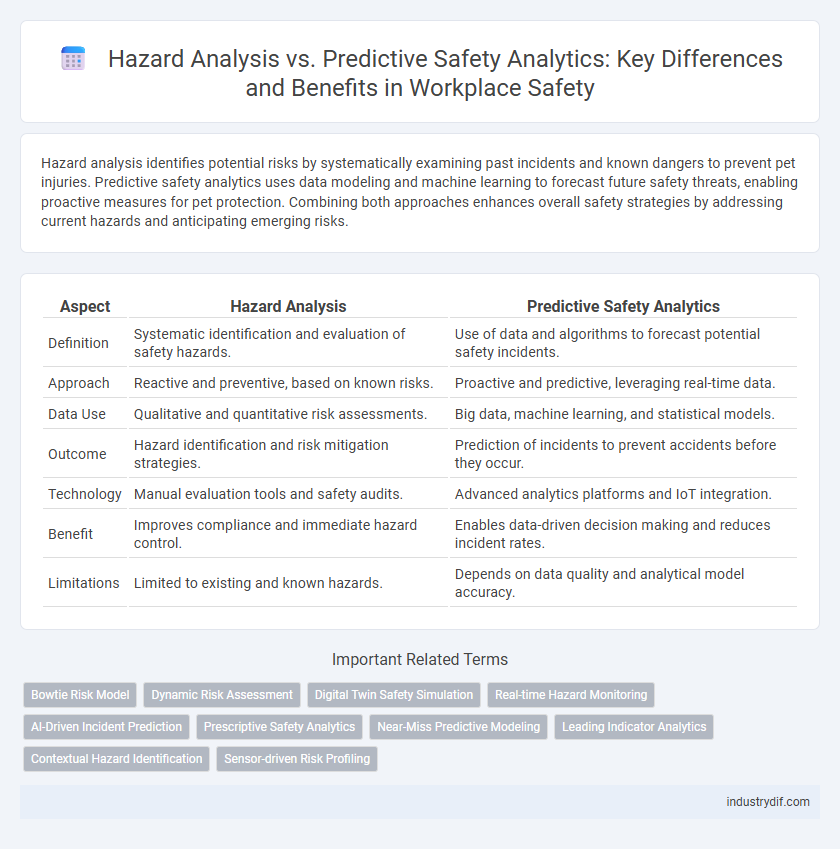

Hazard analysis identifies potential risks by systematically examining past incidents and known dangers to prevent pet injuries. Predictive safety analytics uses data modeling and machine learning to forecast future safety threats, enabling proactive measures for pet protection. Combining both approaches enhances overall safety strategies by addressing current hazards and anticipating emerging risks.

Table of Comparison

| Aspect | Hazard Analysis | Predictive Safety Analytics |

|---|---|---|

| Definition | Systematic identification and evaluation of safety hazards. | Use of data and algorithms to forecast potential safety incidents. |

| Approach | Reactive and preventive, based on known risks. | Proactive and predictive, leveraging real-time data. |

| Data Use | Qualitative and quantitative risk assessments. | Big data, machine learning, and statistical models. |

| Outcome | Hazard identification and risk mitigation strategies. | Prediction of incidents to prevent accidents before they occur. |

| Technology | Manual evaluation tools and safety audits. | Advanced analytics platforms and IoT integration. |

| Benefit | Improves compliance and immediate hazard control. | Enables data-driven decision making and reduces incident rates. |

| Limitations | Limited to existing and known hazards. | Depends on data quality and analytical model accuracy. |

Introduction to Hazard Analysis and Predictive Safety Analytics

Hazard Analysis systematically identifies potential risks and unsafe conditions within a workplace to prevent accidents and ensure compliance with safety regulations. Predictive Safety Analytics leverages data mining, machine learning, and historical incident data to anticipate future hazards and reduce workplace injuries proactively. Combining these methods enhances risk management by providing both foundational hazard awareness and forward-looking insights for safety improvements.

Defining Hazard Analysis in Industrial Safety

Hazard Analysis in industrial safety involves systematically identifying, evaluating, and controlling potential sources of harm within the workplace to prevent accidents and injuries. This process includes methods such as Job Safety Analysis (JSA), Failure Mode and Effects Analysis (FMEA), and Hazard and Operability Study (HAZOP) to assess risks associated with equipment, processes, and human factors. Effective hazard analysis supports compliance with regulatory standards like OSHA and ISO 45001, forming the foundation for risk mitigation strategies in industrial environments.

What Is Predictive Safety Analytics?

Predictive Safety Analytics uses data-driven techniques and machine learning algorithms to identify potential hazards before they cause incidents, enabling proactive risk management. Unlike traditional Hazard Analysis, which relies on historical data and expert judgment to assess existing risks, predictive analytics continuously analyzes real-time data streams from sensors, equipment, and workplace conditions to forecast safety issues. This approach enhances workplace safety by reducing accidents through early detection of patterns that indicate increased risk.

Core Objectives: Hazard Identification vs. Risk Prediction

Hazard analysis centers on the systematic identification and evaluation of potential safety threats within a workplace or process, aiming to mitigate known dangers to prevent incidents. Predictive safety analytics employs data-driven models and machine learning to forecast future risks by analyzing patterns and trends, enabling proactive interventions before hazards materialize. Both approaches enhance workplace safety, with hazard analysis focusing on current threats and predictive analytics targeting future risk mitigation through advanced prediction techniques.

Methodologies: Traditional vs. Data-Driven Approaches

Hazard analysis utilizes traditional methodologies such as failure mode and effects analysis (FMEA) and fault tree analysis (FTA) to systematically identify and evaluate potential risks based on historical incident data and expert judgment. Predictive safety analytics employs data-driven approaches, leveraging machine learning algorithms and real-time sensor data to forecast safety incidents before they occur, enhancing proactive risk management. The shift from manual hazard identification to automated, predictive models marks a significant evolution in safety methodologies, improving accuracy and response times.

Data Sources Used in Hazard Analysis vs. Predictive Analytics

Hazard analysis relies on historical incident reports, safety audits, and regulatory compliance data to identify potential risks and causes of past accidents. Predictive safety analytics incorporates real-time data from IoT sensors, machine learning models, and environmental monitoring systems to forecast future safety hazards and prevent incidents. The integration of structured historical data with unstructured, continuous sensor data enhances the accuracy and responsiveness of predictive safety measures.

Key Benefits and Limitations of Each Approach

Hazard analysis systematically identifies potential risks by evaluating existing processes and past incidents, offering clear insights into known dangers but often missing emerging threats. Predictive safety analytics leverages big data and machine learning to detect patterns and forecast incidents before they occur, enhancing proactive risk management while facing challenges such as data quality and algorithm transparency. Both approaches complement each other, with hazard analysis providing a foundational safety assessment and predictive analytics enabling real-time, data-driven prevention strategies.

Integration of Hazard Analysis with Predictive Analytics

Integrating hazard analysis with predictive safety analytics enhances risk identification by combining traditional qualitative assessments with data-driven predictive models. This fusion allows organizations to anticipate potential hazards through real-time data monitoring, improving proactive safety measures and reducing incident rates. Leveraging both methods creates a comprehensive safety management system that optimizes resource allocation and strengthens overall workplace safety performance.

Real-World Applications in Industrial Settings

Hazard analysis identifies potential risks by systematically examining industrial processes, equipment, and environments to prevent accidents before they occur. Predictive safety analytics leverages historical data, sensor inputs, and machine learning algorithms to forecast safety incidents, enabling proactive interventions in real time. Real-world applications in manufacturing and chemical plants demonstrate that combining hazard analysis with predictive safety analytics significantly reduces workplace injuries and operational downtime.

Future Trends in Safety Management Technologies

Hazard analysis techniques remain essential for identifying potential risks in workplace environments, but predictive safety analytics leverage big data, machine learning, and IoT sensors to anticipate incidents before they occur. Emerging trends in safety management technologies emphasize real-time monitoring, automated risk assessment, and AI-driven decision support systems that transform traditional hazard identification into proactive safety strategies. Integration of cloud computing and wearable devices enhances predictive analytics, enabling organizations to reduce accidents and improve compliance with safety regulations more efficiently.

Related Important Terms

Bowtie Risk Model

The Bowtie Risk Model visually maps hazard scenarios by linking potential causes to preventive barriers and consequences, offering a comprehensive framework for hazard analysis. Predictive Safety Analytics enhances this framework by using data-driven insights to forecast risk trends and optimize control measures, improving proactive safety management.

Dynamic Risk Assessment

Hazard analysis systematically identifies potential sources of harm through static evaluation, while predictive safety analytics leverages real-time data and machine learning to perform dynamic risk assessment, enabling proactive threat mitigation. Dynamic risk assessment continuously adapts to changing conditions by analyzing live sensor inputs, environmental variables, and operational data to predict hazards before they manifest.

Digital Twin Safety Simulation

Hazard analysis identifies potential risks by examining historical safety data and known hazards, while predictive safety analytics leverages digital twin safety simulation to forecast future incidents through real-time data integration and scenario modeling. Digital twin technology enables dynamic risk assessment by replicating physical systems in a virtual environment, allowing organizations to proactively mitigate hazards and enhance workplace safety.

Real-time Hazard Monitoring

Real-time hazard monitoring leverages predictive safety analytics by continuously analyzing data from sensors and operational systems to identify emerging risks before they manifest. Unlike traditional hazard analysis, which relies on static assessments, predictive analytics enables dynamic, data-driven decision-making that enhances workplace safety through immediate hazard detection and response.

AI-Driven Incident Prediction

Hazard analysis identifies potential risks based on historical data and known safety protocols, while predictive safety analytics uses AI-driven incident prediction to analyze real-time data and detect emerging hazards before they occur. AI algorithms enhance safety management by forecasting incidents, enabling proactive interventions that reduce workplace accidents and improve overall risk mitigation.

Prescriptive Safety Analytics

Prescriptive Safety Analytics extends Hazard Analysis and Predictive Safety Analytics by offering actionable recommendations to prevent incidents, leveraging data-driven insights and machine learning algorithms. This approach not only identifies potential hazards and predicts risks but also prescribes specific safety measures, optimizing workplace safety and reducing accident rates effectively.

Near-Miss Predictive Modeling

Hazard analysis systematically identifies potential safety risks by evaluating known hazards and their impact, whereas predictive safety analytics leverages near-miss predictive modeling to analyze historical near-miss data and forecast future incidents with higher accuracy. Near-miss predictive modeling utilizes machine learning algorithms to detect patterns and trends in near-miss events, enabling proactive interventions that significantly reduce workplace accidents and enhance overall safety performance.

Leading Indicator Analytics

Leading Indicator Analytics in predictive safety analytics proactively identifies potential hazards by analyzing real-time data trends and behavioral patterns, enabling organizations to implement preventive measures before incidents occur. In contrast, traditional hazard analysis primarily focuses on reactive identification of known risks and past incidents, limiting its effectiveness in anticipating future safety challenges.

Contextual Hazard Identification

Contextual hazard identification in hazard analysis relies on historical incident data and environmental factors to pinpoint potential risks, while predictive safety analytics harness machine learning algorithms and real-time sensor data to forecast emerging hazards. Integrating contextual insights with predictive models enhances proactive safety measures by anticipating risks within specific operational environments.

Sensor-driven Risk Profiling

Hazard analysis identifies potential risks based on historical incident data and static assessments, while predictive safety analytics leverages real-time sensor data to dynamically profile and anticipate risks before they materialize. Sensor-driven risk profiling enhances accuracy by continuously monitoring environmental and operational parameters, enabling proactive interventions and reducing incident rates in high-risk industrial settings.

Hazard Analysis vs Predictive Safety Analytics Infographic

industrydif.com

industrydif.com