Lockout Tagout (LOTO) involves physically securing energy sources with locks and tags to prevent accidental equipment startup, ensuring worker safety during maintenance. Digital Energy Isolation leverages advanced technology and software controls to remotely deactivate and monitor energy sources, offering enhanced precision and real-time status updates. Both methods prioritize hazard prevention but differ in application, with digital solutions increasing efficiency and reducing human error risks.

Table of Comparison

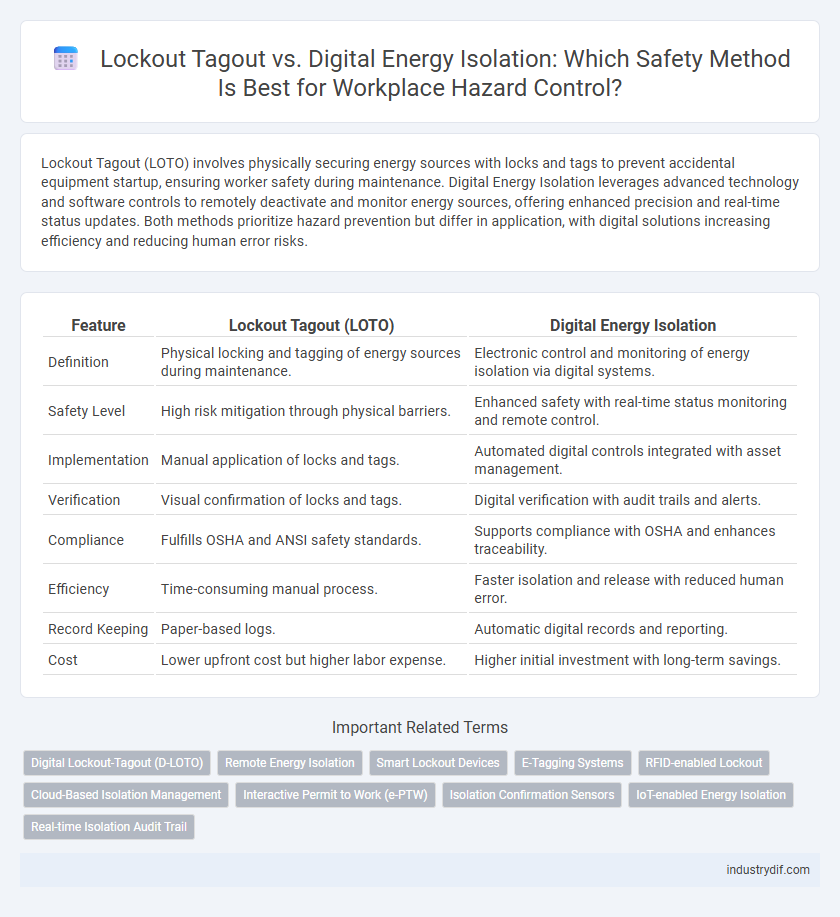

| Feature | Lockout Tagout (LOTO) | Digital Energy Isolation |

|---|---|---|

| Definition | Physical locking and tagging of energy sources during maintenance. | Electronic control and monitoring of energy isolation via digital systems. |

| Safety Level | High risk mitigation through physical barriers. | Enhanced safety with real-time status monitoring and remote control. |

| Implementation | Manual application of locks and tags. | Automated digital controls integrated with asset management. |

| Verification | Visual confirmation of locks and tags. | Digital verification with audit trails and alerts. |

| Compliance | Fulfills OSHA and ANSI safety standards. | Supports compliance with OSHA and enhances traceability. |

| Efficiency | Time-consuming manual process. | Faster isolation and release with reduced human error. |

| Record Keeping | Paper-based logs. | Automatic digital records and reporting. |

| Cost | Lower upfront cost but higher labor expense. | Higher initial investment with long-term savings. |

Introduction to Lockout Tagout (LOTO) and Digital Energy Isolation

Lockout Tagout (LOTO) is a critical safety procedure designed to prevent accidental machine startup during maintenance by physically locking and tagging energy sources. Digital Energy Isolation enhances traditional LOTO by using electronic systems to monitor and control energy isolation remotely, increasing accuracy and reducing human error. Integrating digital solutions with LOTO protocols improves compliance with OSHA standards and promotes safer workplace environments.

Key Differences Between Traditional LOTO and Digital Energy Isolation

Traditional Lockout Tagout (LOTO) relies on physical locks and tags to isolate energy sources, ensuring equipment remains de-energized during maintenance. Digital Energy Isolation uses advanced sensors and software to monitor and control energy isolation remotely, increasing real-time safety visibility and reducing human error. While LOTO is labor-intensive and prone to manual mistakes, digital solutions offer automated compliance tracking and data analytics for enhanced safety management.

Regulatory Compliance: LOTO vs Digital Energy Isolation

Lockout Tagout (LOTO) remains the industry-standard safety protocol mandated by OSHA under standard 29 CFR 1910.147, requiring physical isolation and tagging of energy sources to prevent accidental machine startup during maintenance. Digital Energy Isolation, while innovative, lacks comprehensive regulatory recognition and integration into federal safety standards, posing challenges for compliance verification and enforcement. Organizations adopting digital methods must ensure alignment with existing LOTO regulations or seek updated guidelines to maintain regulatory compliance and worker safety.

Advantages of Digital Energy Isolation Over Traditional Methods

Digital Energy Isolation enhances workplace safety by providing real-time monitoring and remote control capabilities, reducing human error associated with traditional Lockout Tagout procedures. It offers precise verification of energy sources status through automated sensors, ensuring complete de-energization before maintenance begins. The integration of digital systems streamlines compliance tracking and audit accuracy, leading to improved regulatory adherence and reduced downtime.

Common Challenges in Implementing Lockout Tagout

Lockout Tagout (LOTO) faces common challenges such as human error in equipment identification, prolonged downtime due to manual processes, and inconsistencies in adherence to safety protocols. Digital Energy Isolation offers enhanced accuracy through automated system controls and real-time monitoring, reducing the risk of accidental energy release. Transitioning to digital solutions addresses these challenges by streamlining procedures and improving compliance tracking.

Enhanced Safety Outcomes with Digital Energy Isolation

Digital Energy Isolation significantly improves safety outcomes by providing real-time monitoring and remote control capabilities, which minimize human error and ensure complete de-energization of equipment. Unlike traditional Lockout Tagout methods, digital systems offer automated verification processes and detailed audit trails, enhancing compliance with safety regulations. These advanced features reduce workplace accidents and increase overall operational safety in industrial environments.

Technology Integration in Energy Isolation Procedures

Digital Energy Isolation enhances traditional Lockout Tagout by integrating smart sensors and IoT devices to monitor energy sources in real-time, significantly reducing the risk of accidental energization. Technology integration allows automated verification and remote communication, ensuring compliance with safety protocols and improving worker protection. This shift towards digital systems streamlines energy isolation procedures, increasing overall operational efficiency and reducing human error.

Training Requirements: Traditional vs Digital Systems

Traditional Lockout Tagout (LOTO) training emphasizes hands-on procedures, physical lock identification, and compliance with OSHA standards for mechanical energy control. Digital Energy Isolation systems require comprehensive education on software interfaces, real-time monitoring, and cybersecurity measures to prevent unauthorized access or system bypass. Effective training for both methods mandates regular updates to ensure worker competency and adherence to evolving safety protocols.

Case Studies: Industry Adoption of Digital Energy Isolation

Case studies reveal significant industry adoption of Digital Energy Isolation, showcasing enhanced compliance and reduced incident rates compared to traditional Lockout Tagout methods. Manufacturing and energy sectors report improved worker safety and streamlined maintenance processes through digital systems that provide real-time monitoring and remote control of hazardous energy sources. These successes demonstrate Digital Energy Isolation's effectiveness in minimizing human error and ensuring robust safety protocols in complex industrial environments.

Future Trends in Safety: The Shift Towards Digital Solutions

Digital energy isolation is revolutionizing lockout tagout procedures by integrating real-time monitoring and remote control capabilities, significantly enhancing workplace safety. Future trends emphasize the adoption of Internet of Things (IoT) devices and automated systems to minimize human error and streamline energy isolation processes. Advanced analytics and cloud-based platforms enable predictive maintenance and proactive hazard identification, driving a shift towards more efficient and reliable safety protocols.

Related Important Terms

Digital Lockout-Tagout (D-LOTO)

Digital Lockout-Tagout (D-LOTO) enhances traditional lockout tagout procedures by integrating digital controls, real-time monitoring, and automated documentation to improve energy isolation safety and regulatory compliance. This technology reduces human error, accelerates workflow efficiency, and provides detailed audit trails, making it a superior solution for managing hazardous energy in industrial settings.

Remote Energy Isolation

Remote energy isolation enhances Lockout Tagout (LOTO) procedures by enabling workers to control hazardous energy sources from a distance, reducing exposure to risks during maintenance. Digital energy isolation systems offer real-time monitoring and verification, improving safety compliance and minimizing human error compared to traditional manual LOTO methods.

Smart Lockout Devices

Smart lockout devices enhance traditional Lockout Tagout procedures by integrating digital energy isolation technology, enabling real-time monitoring and remote control of equipment status to prevent accidental startup during maintenance. These innovative systems improve workplace safety by ensuring precise energy control, reducing human error, and providing electronic audit trails for compliance verification.

E-Tagging Systems

Lockout Tagout (LOTO) procedures have traditionally relied on physical locks and tags to ensure machinery remains de-energized during maintenance, but Digital Energy Isolation systems, such as E-Tagging, enhance safety by enabling real-time monitoring and remote control of energy sources. E-Tagging systems improve compliance and reduce human error by providing a centralized digital platform that tracks isolation status and authorization, significantly increasing workplace safety and operational efficiency.

RFID-enabled Lockout

RFID-enabled Lockout Tagout enhances safety protocols by utilizing digital energy isolation to accurately identify and control hazardous energy sources, reducing human error and increasing compliance in industrial environments. This smart technology streamlines lockout procedures, enabling faster verification and real-time monitoring of locked-out equipment to prevent accidental energy release.

Cloud-Based Isolation Management

Cloud-based isolation management revolutionizes traditional Lockout Tagout (LOTO) procedures by enabling real-time tracking, remote authorization, and comprehensive audit trails for energy isolation activities. Leveraging digital energy isolation enhances worker safety compliance and reduces human error through automated alerts and centralized data accessibility.

Interactive Permit to Work (e-PTW)

Lockout Tagout (LOTO) procedures are critical for ensuring worker safety by physically isolating hazardous energy sources, while Digital Energy Isolation enhances this process through Interactive Permit to Work (e-PTW) systems that streamline real-time communication, authorization, and compliance tracking. Implementing e-PTW in digital energy isolation reduces human error, accelerates permit validations, and provides auditable records, significantly improving safety management in industrial environments.

Isolation Confirmation Sensors

Lockout Tagout procedures rely on physical locks and tags to prevent equipment energization, but Digital Energy Isolation enhances safety by integrating isolation confirmation sensors that continuously monitor and verify energy isolation status in real-time. These sensors reduce human error by providing automated alerts and documentation, ensuring comprehensive hazard control and compliance with OSHA standards.

IoT-enabled Energy Isolation

Lockout Tagout traditionally prevents machine startup during maintenance by using physical locks and tags, whereas IoT-enabled Digital Energy Isolation enhances safety through real-time monitoring, remote control, and automated compliance verification, reducing human error and enabling faster response times. IoT integration allows for centralized data collection and analytics, improving energy isolation procedures by providing timely alerts and predictive maintenance insights for critical equipment.

Real-time Isolation Audit Trail

Lockout Tagout systems traditionally rely on physical locks and manual logs to prevent equipment energization, but Digital Energy Isolation platforms offer a real-time isolation audit trail that enhances safety compliance by automatically recording and monitoring isolation status. This digital solution reduces human error and provides instant access to accurate data, improving decision-making and ensuring regulatory adherence in hazardous energy control processes.

Lockout Tagout vs Digital Energy Isolation Infographic

industrydif.com

industrydif.com