Traditional safety audits rely on retrospective data review and checklist compliance to identify hazards after incidents occur, often missing emerging risks. Predictive safety analytics leverage real-time data, machine learning, and trend analysis to anticipate potential safety breaches before they happen, enhancing proactive risk management. This shift from reactive to predictive methods significantly improves pet safety by enabling timely interventions and reducing incident rates.

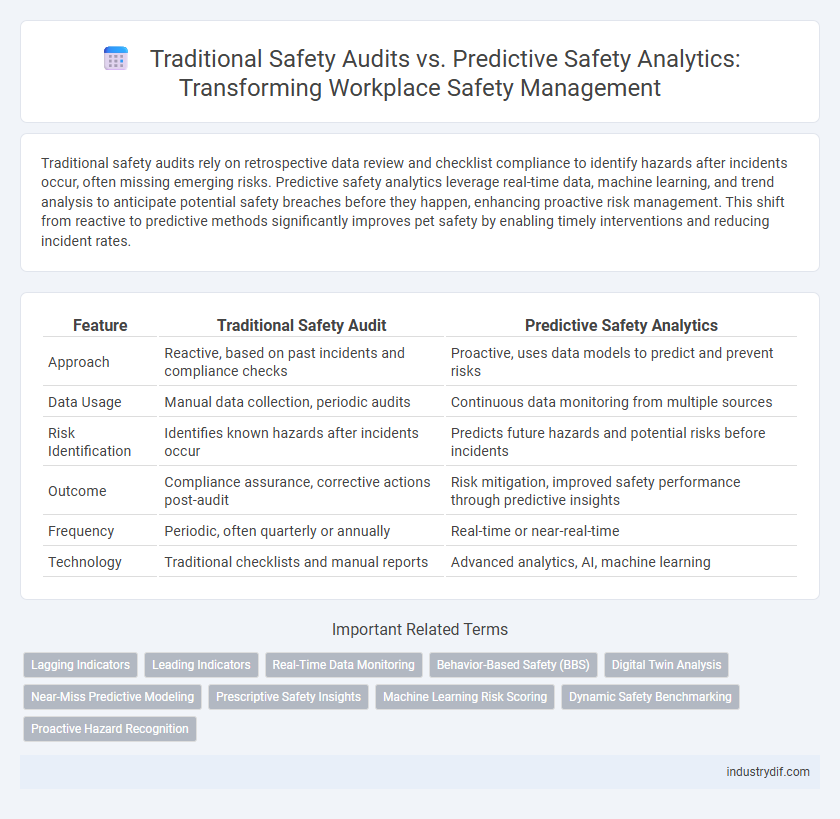

Table of Comparison

| Feature | Traditional Safety Audit | Predictive Safety Analytics |

|---|---|---|

| Approach | Reactive, based on past incidents and compliance checks | Proactive, uses data models to predict and prevent risks |

| Data Usage | Manual data collection, periodic audits | Continuous data monitoring from multiple sources |

| Risk Identification | Identifies known hazards after incidents occur | Predicts future hazards and potential risks before incidents |

| Outcome | Compliance assurance, corrective actions post-audit | Risk mitigation, improved safety performance through predictive insights |

| Frequency | Periodic, often quarterly or annually | Real-time or near-real-time |

| Technology | Traditional checklists and manual reports | Advanced analytics, AI, machine learning |

Introduction to Safety Practices in Industry

Traditional safety audits rely on periodic inspections and historical incident reports to identify workplace hazards and ensure compliance with safety regulations. Predictive safety analytics utilize real-time data and machine learning algorithms to forecast potential risks and prevent accidents before they occur. Integrating predictive safety analytics enhances proactive risk management and improves overall industrial safety performance.

Defining Traditional Safety Audits

Traditional safety audits involve systematic inspections and reviews of workplace conditions, compliance with safety regulations, and documentation verification to identify existing hazards. These audits rely heavily on historical data, physical observations, and manual reporting to evaluate safety performance and ensure adherence to established protocols. The process is typically periodic, focusing on past and current safety states rather than forecasting potential future risks.

Fundamentals of Predictive Safety Analytics

Predictive safety analytics transforms traditional safety audits by leveraging real-time data and advanced algorithms to identify potential hazards before incidents occur. This approach integrates machine learning models and historical safety records to forecast risks, enabling proactive interventions and reducing workplace accidents. Emphasizing continuous data monitoring and predictive modeling enhances overall safety management effectiveness compared to retrospective audit methods.

Key Differences Between Audit and Analytics Approaches

Traditional safety audits rely on periodic inspections and compliance checklists to identify hazards and ensure regulatory adherence, providing a retrospective view of workplace safety. Predictive safety analytics utilize real-time data, machine learning, and trend analysis to forecast potential incidents and proactively mitigate risks. The key difference lies in the proactive, data-driven approach of predictive analytics versus the reactive, compliance-focused nature of traditional audits.

Scope and Limitations of Traditional Safety Audits

Traditional safety audits primarily focus on identifying compliance gaps and observable hazards through periodic inspections and checklist evaluations, often limited to retrospective data analysis. Their scope is confined to surface-level issues without integrating real-time data or predictive insights, resulting in delayed hazard detection and reactive safety management. This limitation restricts the ability to foresee potential risks and implement proactive measures critical for dynamic and complex operational environments.

Advantages of Predictive Safety Analytics in Risk Management

Predictive Safety Analytics leverages real-time data and machine learning algorithms to identify potential hazards before they result in incidents, significantly enhancing risk management. Unlike Traditional Safety Audits that rely on periodic inspections and historical records, predictive analytics continuously monitors safety indicators and provides actionable insights for proactive intervention. This approach reduces workplace accidents, minimizes downtime, and improves compliance by enabling early detection and mitigation of emerging risks.

Data-Driven Decision-Making in Safety Programs

Traditional safety audits rely on historical data and periodic inspections to identify hazards and compliance gaps, often resulting in reactive measures. Predictive safety analytics leverage real-time data, machine learning algorithms, and risk modeling to anticipate incidents before they occur, enabling proactive interventions. Implementing data-driven decision-making enhances safety programs by optimizing resource allocation, reducing workplace accidents, and improving overall risk management.

Implementation Challenges and Best Practices

Traditional safety audits face challenges like resource intensiveness, periodic assessment gaps, and reactive identification of hazards, limiting timely interventions. Predictive safety analytics implementation demands high-quality data integration, advanced analytical skills, and continuous monitoring frameworks to proactively identify risks. Best practices include fostering cross-functional collaboration, investing in robust data infrastructure, and iterative model validation for effective risk mitigation.

Case Studies: Real-World Applications and Outcomes

Case studies demonstrate that traditional safety audits often identify hazards after incidents occur, resulting in reactive measures with limited prevention. Predictive safety analytics leverage real-time data and machine learning algorithms to forecast potential risks, enabling proactive interventions that reduce workplace accidents significantly. Organizations using predictive models report up to a 30% decrease in injury rates and enhanced compliance with safety regulations compared to those relying solely on traditional audits.

Future Trends in Industrial Safety Management

Predictive safety analytics leverages real-time data and machine learning algorithms to identify potential hazards before they occur, surpassing traditional safety audits that rely on historical data and manual inspections. Future trends in industrial safety management emphasize the integration of IoT sensors, AI-driven risk assessments, and automated reporting to enhance proactive decision-making. This shift enables companies to minimize workplace incidents and improve compliance with evolving safety regulations through continuous monitoring and predictive insights.

Related Important Terms

Lagging Indicators

Traditional safety audits rely heavily on lagging indicators such as injury rates and incident reports, which reflect past safety performance and often delay corrective actions. Predictive safety analytics, while incorporating lagging indicators, enhance safety management by using real-time data and advanced algorithms to forecast potential hazards and prevent future incidents.

Leading Indicators

Traditional safety audits rely on lagging indicators such as past incidents and compliance checks, which often detect issues only after they have occurred. Predictive safety analytics focus on leading indicators like behavioral patterns, real-time hazard detection, and near-miss data to proactively identify risks and prevent accidents before they happen.

Real-Time Data Monitoring

Traditional safety audits rely on periodic inspections and historical data, which can delay hazard detection and response times. Predictive safety analytics utilize real-time data monitoring from IoT sensors and wearable devices to identify potential risks instantly, enabling proactive interventions that significantly reduce workplace accidents.

Behavior-Based Safety (BBS)

Traditional Safety Audits rely on retrospective data collection and checklist compliance to identify hazards, while Predictive Safety Analytics utilize real-time behavior-based safety (BBS) data to forecast and prevent incidents before they occur. Integrating BBS insights with predictive models enhances workplace safety by proactively addressing risky behaviors and improving employee engagement in hazard identification.

Digital Twin Analysis

Traditional safety audits rely on periodic inspections and manual data collection, often missing real-time hazard detection, while predictive safety analytics leverage Digital Twin technology to simulate workplace conditions and predict potential risks proactively. Digital Twin analysis integrates IoT sensor data and machine learning models to provide continuous monitoring, enabling organizations to identify safety vulnerabilities and prevent incidents before they occur.

Near-Miss Predictive Modeling

Traditional safety audits rely on retrospective data and manual inspections to identify hazards, often missing subtle patterns leading to incidents. Near-miss predictive modeling in predictive safety analytics leverages real-time data and machine learning algorithms to detect potential risks before accidents occur, significantly improving proactive safety management and reducing workplace injuries.

Prescriptive Safety Insights

Traditional safety audits rely on retrospective data analysis to identify risks, often leading to reactive measures, whereas predictive safety analytics utilize real-time data and machine learning algorithms to forecast potential hazards and prescribe targeted interventions. Prescriptive safety insights enhance decision-making by recommending specific actions that mitigate risks proactively, reducing workplace incidents and improving overall safety performance.

Machine Learning Risk Scoring

Machine Learning Risk Scoring in Predictive Safety Analytics leverages historical data and real-time inputs to identify potential hazards with higher accuracy than Traditional Safety Audits, which rely on periodic, manual inspections. This advanced approach enables proactive risk mitigation by continuously analyzing patterns and predicting incidents before they occur, significantly enhancing workplace safety outcomes.

Dynamic Safety Benchmarking

Traditional safety audits rely on static checklists and periodic assessments that provide limited insights into evolving workplace hazards, whereas predictive safety analytics utilize real-time data and machine learning algorithms to identify emerging risks and trends. Dynamic safety benchmarking continuously adjusts performance metrics based on current operational conditions, enabling proactive incident prevention and targeted safety improvements.

Proactive Hazard Recognition

Traditional safety audits rely on retrospective hazard identification through manual inspections and checklist evaluations, often detecting issues after incidents occur. Predictive safety analytics harness real-time data and machine learning algorithms to proactively recognize potential hazards, enabling timely interventions that prevent accidents before they happen.

Traditional Safety Audit vs Predictive Safety Analytics Infographic

industrydif.com

industrydif.com