Lockout/Tagout procedures physically secure energy sources to prevent accidental machine startup during maintenance, ensuring worker safety by clearly signaling hazards. Remote isolation systems enhance safety by allowing operators to control and isolate energy sources from a safe distance, reducing exposure to dangerous equipment. Both methods are essential for preventing accidents, but remote isolation offers increased flexibility and minimizes direct contact with hazardous machinery.

Table of Comparison

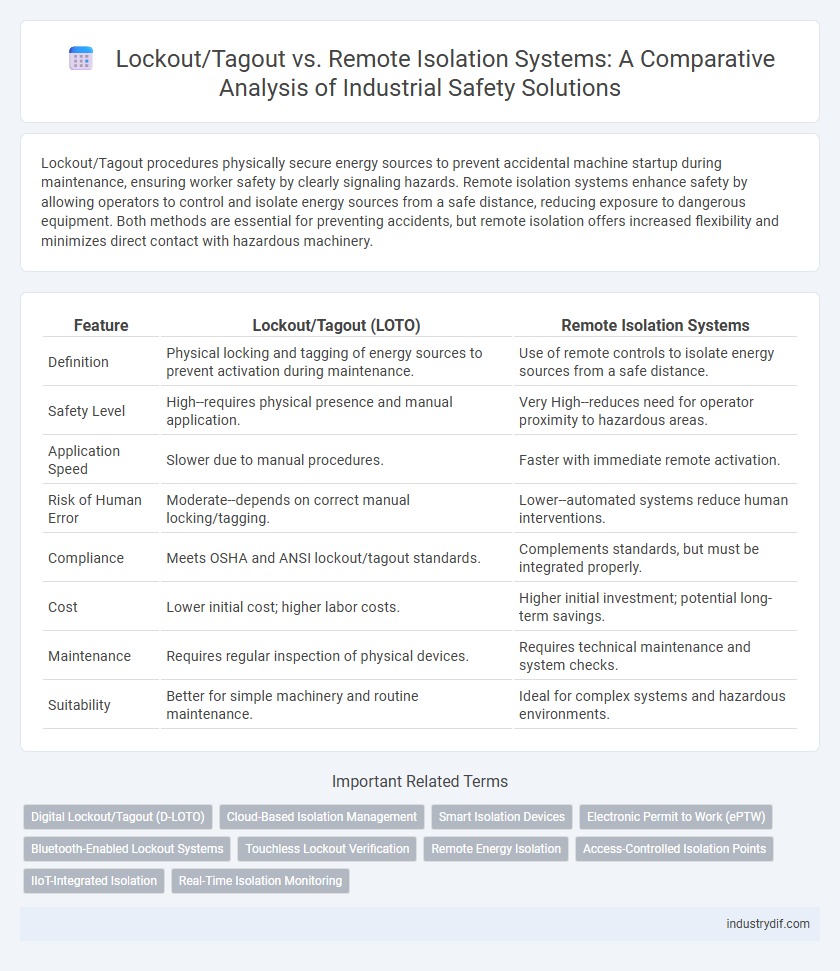

| Feature | Lockout/Tagout (LOTO) | Remote Isolation Systems |

|---|---|---|

| Definition | Physical locking and tagging of energy sources to prevent activation during maintenance. | Use of remote controls to isolate energy sources from a safe distance. |

| Safety Level | High--requires physical presence and manual application. | Very High--reduces need for operator proximity to hazardous areas. |

| Application Speed | Slower due to manual procedures. | Faster with immediate remote activation. |

| Risk of Human Error | Moderate--depends on correct manual locking/tagging. | Lower--automated systems reduce human interventions. |

| Compliance | Meets OSHA and ANSI lockout/tagout standards. | Complements standards, but must be integrated properly. |

| Cost | Lower initial cost; higher labor costs. | Higher initial investment; potential long-term savings. |

| Maintenance | Requires regular inspection of physical devices. | Requires technical maintenance and system checks. |

| Suitability | Better for simple machinery and routine maintenance. | Ideal for complex systems and hazardous environments. |

Understanding Lockout/Tagout: Principles and Practices

Lockout/Tagout (LOTO) involves physically isolating energy sources by applying locks and tags to equipment, ensuring machinery remains de-energized during maintenance to prevent accidental startup. Core principles include identifying all energy sources, isolating and securing them, verifying zero energy state, and controlling stored or residual energy. Proper LOTO practices are essential for compliance with OSHA standards and significantly reduce workplace injuries from unexpected equipment energization.

Remote Isolation Systems: Definition and Applications

Remote isolation systems are safety mechanisms designed to control hazardous energy sources from a distance, preventing accidental machine startup during maintenance. These systems use wireless or wired technology to isolate energy remotely, enhancing worker safety by minimizing physical exposure to dangerous equipment. Common applications include industrial machinery, electrical panels, and chemical processes where direct lockout/tagout procedures may be challenging or riskier.

Key Differences Between Lockout/Tagout and Remote Isolation

Lockout/Tagout (LOTO) procedures physically isolate energy sources by applying locks and tags directly to equipment to prevent accidental activation during maintenance. Remote Isolation Systems use automated controls to shut off or isolate hazardous energy from a distance, minimizing human intervention and enhancing operational efficiency. Key differences include the manual versus automated nature of isolation, the levels of physical presence required, and the potential reduction in human error through remote monitoring technologies.

Safety Improvements with Remote Isolation Technologies

Remote isolation systems significantly enhance workplace safety by reducing the need for physical presence near hazardous equipment during lockout/tagout procedures. These technologies enable operators to control energy sources from a safe distance, minimizing exposure to electrical, mechanical, or chemical hazards. Implementing remote isolation improves compliance with safety standards and lowers the risk of accidents and lockout/tagout-related injuries.

Compliance Requirements: LOTO vs Remote Isolation

Lockout/Tagout (LOTO) compliance requires physical lock devices and tags to isolate energy sources during maintenance, adhering to OSHA standards 29 CFR 1910.147. Remote Isolation Systems meet compliance by enabling energy isolation from a safe distance, reducing exposure risks, and must still fulfill control verification and signage protocols. Both methods mandate strict adherence to documented procedures, employee training, and periodic inspections to ensure effective hazard prevention.

Risk Assessment: Which System Offers Better Hazard Control?

Lockout/Tagout (LOTO) systems provide robust risk assessment frameworks by physically isolating energy sources, ensuring machinery remains de-energized during maintenance and reducing accidental startup hazards. Remote isolation systems enhance hazard control by allowing operators to deactivate equipment from a safe distance, minimizing exposure to dangerous energy sources and enabling real-time monitoring of isolation status. Evaluating both methods through comprehensive risk assessments reveals that combining LOTO's physical barriers with remote isolation's technological controls offers superior protection against energy-related incidents.

Human Factors: Operator Involvement and Training Implications

Lockout/Tagout procedures demand direct operator involvement for the physical isolation of energy sources, requiring comprehensive training on equipment-specific steps to prevent accidental energization. Remote isolation systems reduce the need for manual interaction, minimizing human error but necessitating advanced technical training focused on system monitoring and emergency override capabilities. Both methods emphasize human factors, with Lockout/Tagout relying on procedural discipline and Remote Isolation systems depending on operator proficiency with digital controls.

Integration Challenges: Upgrading from LOTO to Remote Isolation

Upgrading from Lockout/Tagout (LOTO) to Remote Isolation Systems presents significant integration challenges, including compatibility with existing equipment and ensuring seamless communication between control devices. Facility managers must address potential cybersecurity risks and provide comprehensive training to ensure personnel safety and procedural compliance. Balancing physical lockout methods with digital isolation technologies requires meticulous planning to maintain regulatory adherence and operational efficiency.

Cost-Benefit Analysis: Implementation and Maintenance

Lockout/Tagout systems typically involve lower initial implementation costs but require extensive manual labor for maintenance and compliance monitoring, increasing long-term expenses. Remote isolation systems demand higher upfront investment due to advanced technology integration but reduce operational downtime and enhance worker safety, leading to significant cost savings over time. Analyzing the trade-offs between immediate implementation costs and ongoing maintenance expenses is crucial for optimizing safety budgets and ensuring regulatory adherence.

Future Trends in Industrial Isolation Safety

Emerging trends in industrial isolation safety emphasize the integration of remote isolation systems with classic Lockout/Tagout procedures to enhance efficiency and reduce human error. Advanced IoT sensors and real-time monitoring enable proactive identification of hazardous conditions, allowing safer isolation and maintenance operations. Artificial intelligence-driven analytics will further optimize safety protocols by predicting potential failures and ensuring compliance with evolving regulatory standards.

Related Important Terms

Digital Lockout/Tagout (D-LOTO)

Digital Lockout/Tagout (D-LOTO) systems enhance safety by providing real-time monitoring, remote control capabilities, and detailed audit trails that surpass traditional Lockout/Tagout and Remote Isolation methods. These systems minimize human error and downtime by integrating IoT sensors and centralized digital platforms for more efficient energy-isolation management.

Cloud-Based Isolation Management

Cloud-based isolation management systems enhance Lockout/Tagout (LOTO) procedures by providing real-time monitoring, secure audit trails, and remote control capabilities that significantly reduce human error and improve compliance with safety regulations. These systems enable efficient tracking and verification of isolation status across multiple sites, increasing overall operational safety and minimizing downtime during maintenance activities.

Smart Isolation Devices

Smart isolation devices enhance safety by integrating Lockout/Tagout procedures with remote isolation systems, reducing human error and ensuring precise control over hazardous energy sources. These technologies provide real-time monitoring and automated lockout capabilities, significantly minimizing the risk of accidental equipment startup during maintenance.

Electronic Permit to Work (ePTW)

Electronic Permit to Work (ePTW) systems streamline Lockout/Tagout and Remote Isolation processes by enhancing control, tracking, and authorization of hazardous energy isolation activities, significantly reducing human error and improving compliance with safety regulations. Integration of ePTW enables real-time monitoring and documentation, ensuring accurate work permits and secure isolation procedures that protect personnel from unexpected energy releases.

Bluetooth-Enabled Lockout Systems

Bluetooth-enabled lockout systems enhance safety by providing real-time monitoring and control over hazardous energy sources, significantly reducing the risk of accidental machine startups during maintenance. These remote isolation systems streamline lockout/tagout procedures by enabling authorized personnel to apply and verify locks digitally, improving compliance and minimizing human error.

Touchless Lockout Verification

Touchless lockout verification enhances safety protocols by allowing workers to confirm machinery isolation remotely, eliminating the risk of accidental contact with energized equipment. Remote isolation systems integrated with lockout/tagout procedures improve compliance and reduce human error by providing real-time status updates and digital audit trails.

Remote Energy Isolation

Remote Energy Isolation systems enhance workplace safety by enabling the control of hazardous energy sources from a distance, reducing direct exposure risks associated with traditional Lockout/Tagout methods. These systems integrate advanced monitoring and control technologies to ensure secure and efficient isolation of machinery during maintenance or emergency situations.

Access-Controlled Isolation Points

Access-controlled isolation points in lockout/tagout systems enhance safety by physically securing energy sources to prevent accidental activation during maintenance, ensuring only authorized personnel can restore operation. Remote isolation systems add an advanced layer by enabling energy control from a distance, reducing employee exposure to hazards and streamlining the lockout process.

IIoT-Integrated Isolation

IIoT-integrated isolation systems enhance Lockout/Tagout procedures by enabling remote monitoring and control of hazardous energy sources, significantly reducing human error and exposure risks. These systems provide real-time data analytics and automated verification, improving overall safety compliance and operational efficiency in industrial environments.

Real-Time Isolation Monitoring

Lockout/Tagout procedures provide physical barriers to equipment energy sources, while remote isolation systems enable real-time isolation monitoring through sensors and automated controls, enhancing worker safety by continuously verifying isolation status. Real-time isolation monitoring reduces the risk of accidental energization by offering instant alerts and detailed status updates, far surpassing the static, manual verification methods of traditional Lockout/Tagout.

Lockout/Tagout vs Remote Isolation Systems Infographic

industrydif.com

industrydif.com