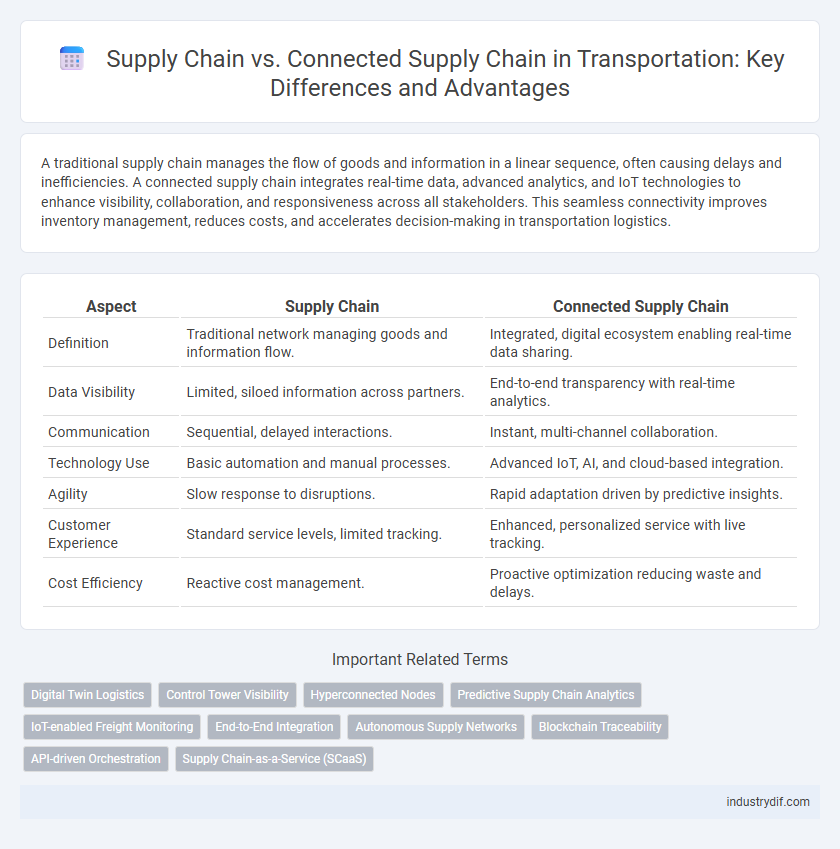

A traditional supply chain manages the flow of goods and information in a linear sequence, often causing delays and inefficiencies. A connected supply chain integrates real-time data, advanced analytics, and IoT technologies to enhance visibility, collaboration, and responsiveness across all stakeholders. This seamless connectivity improves inventory management, reduces costs, and accelerates decision-making in transportation logistics.

Table of Comparison

| Aspect | Supply Chain | Connected Supply Chain |

|---|---|---|

| Definition | Traditional network managing goods and information flow. | Integrated, digital ecosystem enabling real-time data sharing. |

| Data Visibility | Limited, siloed information across partners. | End-to-end transparency with real-time analytics. |

| Communication | Sequential, delayed interactions. | Instant, multi-channel collaboration. |

| Technology Use | Basic automation and manual processes. | Advanced IoT, AI, and cloud-based integration. |

| Agility | Slow response to disruptions. | Rapid adaptation driven by predictive insights. |

| Customer Experience | Standard service levels, limited tracking. | Enhanced, personalized service with live tracking. |

| Cost Efficiency | Reactive cost management. | Proactive optimization reducing waste and delays. |

Defining Traditional Supply Chain in Transportation

The traditional supply chain in transportation involves the linear movement of goods from suppliers to manufacturers, distributors, and end customers, with minimal real-time data integration or collaboration between stakeholders. It relies heavily on scheduled shipments, manual tracking, and isolated information systems that limit visibility and responsiveness. This approach often results in inefficiencies, delayed deliveries, and higher operational costs due to the lack of connectivity and dynamic coordination.

Introduction to Connected Supply Chain

A connected supply chain integrates advanced digital technologies such as IoT, AI, and cloud computing to enable real-time data sharing and enhanced visibility across all logistics and transportation nodes. This transformation reduces delays and optimizes inventory management by providing precise tracking and predictive analytics throughout the supply network. The shift from traditional supply chains to connected systems drives increased efficiency, agility, and responsiveness in global transportation and distribution operations.

Key Differences: Supply Chain vs Connected Supply Chain

Supply chains primarily rely on linear, manual processes with limited real-time visibility and data sharing across partners. Connected supply chains leverage IoT, advanced analytics, and integrated digital platforms to enable real-time tracking, enhanced collaboration, and proactive decision-making. This transformation results in improved efficiency, reduced costs, and increased responsiveness to market demands.

Technology Integration in Connected Supply Chains

Technology integration in connected supply chains enables real-time data exchange across suppliers, manufacturers, and logistics providers, enhancing visibility and decision-making. Advanced IoT sensors, AI-driven analytics, and blockchain solutions facilitate seamless communication and traceability, reducing delays and increasing efficiency. This integration transforms traditional supply chains into dynamic networks capable of rapid response to disruptions and market demands.

Real-Time Visibility and Tracking

Real-time visibility and tracking in transportation transform traditional supply chains into connected supply chains by enabling instantaneous monitoring of shipments and inventory status. Connected supply chains leverage IoT devices, GPS, and cloud-based platforms to provide end-to-end transparency, reducing delays and improving decision-making accuracy. This enhanced data integration facilitates proactive management of logistics, leading to optimized route planning and increased supply chain resilience.

Impact on Operational Efficiency

A connected supply chain integrates real-time data sharing across suppliers, manufacturers, and logistics providers, significantly enhancing operational efficiency by reducing delays and minimizing inventory costs. This seamless communication enables proactive decision-making, leading to faster response times and improved resource allocation. Traditional supply chains often suffer from information silos, resulting in inefficiencies and slower throughput.

Collaboration Across the Transportation Network

Collaboration across the transportation network in a connected supply chain leverages real-time data sharing and integrated communication platforms to synchronize operations among carriers, suppliers, and distributors. This connectivity enhances route optimization, reduces transit times, and improves inventory management through predictive analytics and dynamic resource allocation. Traditional supply chains lack this level of interconnectedness, often resulting in delays, inefficiencies, and limited visibility across the entire transportation ecosystem.

Risk Management and Resilience

Traditional supply chains often lack real-time visibility, making risk management reactive and increasing vulnerability to disruptions. Connected supply chains leverage IoT, AI, and advanced analytics to provide proactive risk identification, enabling faster response and enhanced resilience. This integration minimizes delays, reduces costs, and ensures continuity in transportation networks despite unforeseen challenges.

Cost Implications and ROI

Traditional supply chains often face high operational costs due to inefficiencies in inventory management, transportation delays, and lack of real-time data. Connected supply chains leverage IoT and AI technologies to optimize route planning, reduce lead times, and improve demand forecasting, significantly lowering costs and enhancing asset utilization. Companies investing in connected supply chain systems report faster ROI through decreased capital expenditures and improved responsiveness to market fluctuations.

Future Trends in Connected Transportation Supply Chains

Future trends in connected transportation supply chains emphasize real-time data integration, leveraging IoT devices and AI for enhanced visibility and predictive analytics. Blockchain technology ensures secure, transparent transactions across the supply chain, reducing delays and fraud. Autonomous vehicles and smart infrastructure further optimize efficiency, lowering operational costs and improving delivery accuracy.

Related Important Terms

Digital Twin Logistics

Supply chain management integrates digital twin logistics to create a connected supply chain, simulating real-time operations and enabling predictive analytics for enhanced decision-making. Digital twin technology in transportation optimizes route planning, inventory management, and risk mitigation by providing accurate virtual representations of physical assets and processes.

Control Tower Visibility

A traditional supply chain often suffers from fragmented data and limited real-time insight, hindering proactive decision-making and responsiveness. In contrast, a connected supply chain leverages control tower visibility, enabling centralized monitoring, end-to-end transparency, and faster identification of disruptions to optimize transportation efficiency and reduce costs.

Hyperconnected Nodes

Hyperconnected nodes in a connected supply chain enable seamless real-time data exchange across transportation hubs, enhancing route optimization and reducing transit times. This integration surpasses traditional supply chain limitations by fostering predictive analytics and dynamic decision-making for efficient goods movement.

Predictive Supply Chain Analytics

Predictive Supply Chain Analytics leverages advanced machine learning algorithms and real-time data integration to transform traditional supply chains into connected supply chains, enhancing demand forecasting accuracy and inventory optimization. This connectivity enables proactive disruption management and improved decision-making across transportation networks, reducing costs and increasing efficiency throughout the supply chain.

IoT-enabled Freight Monitoring

IoT-enabled freight monitoring transforms traditional supply chains by providing real-time tracking of shipments, enhancing visibility, and reducing delays through continuous data exchange between assets. Connected supply chains leverage this technology to optimize route planning, improve inventory management, and increase overall transportation efficiency.

End-to-End Integration

End-to-End Integration in a Connected Supply Chain enables real-time data sharing and synchronized operations across all transportation nodes, enhancing visibility, efficiency, and responsiveness. Traditional supply chains often lack this seamless connectivity, leading to delays, increased costs, and fragmented information flows throughout the transportation network.

Autonomous Supply Networks

Autonomous Supply Networks (ASNs) leverage real-time data integration and AI-driven automation to create adaptive, interconnected transportation systems that optimize supply chain efficiency and responsiveness. These networks enable seamless coordination across logistics, inventory, and delivery, surpassing traditional supply chains by minimizing delays and reducing operational costs through predictive analytics and self-correcting mechanisms.

Blockchain Traceability

Blockchain traceability enhances traditional supply chains by enabling real-time tracking of goods, ensuring data integrity, and reducing fraud through decentralized ledgers. Connected supply chains leverage this technology to improve transparency, optimize inventory management, and enhance collaboration among stakeholders across the transportation network.

API-driven Orchestration

API-driven orchestration in connected supply chains enables real-time data integration and automated workflows across multiple transportation partners, enhancing visibility and responsiveness. This advanced coordination reduces delays, optimizes route planning, and improves overall supply chain efficiency compared to traditional supply chains.

Supply Chain-as-a-Service (SCaaS)

Supply Chain-as-a-Service (SCaaS) transforms traditional supply chains into connected ecosystems by leveraging real-time data integration, AI-driven analytics, and cloud-based platforms to enhance visibility, agility, and efficiency in transportation logistics. This service-centric model reduces operational costs and accelerates decision-making, enabling seamless coordination between suppliers, carriers, and distributors across global supply networks.

Supply Chain vs Connected Supply Chain Infographic

industrydif.com

industrydif.com