Hazardous waste reclamation involves safely processing dangerous materials like chemicals, solvents, and heavy metals to reduce environmental impact and recover valuable components. E-waste reclamation specifically targets electronic devices, extracting precious metals and recyclable parts while properly managing toxic substances such as lead and mercury. Both processes require specialized techniques to ensure human health and environmental protection during disposal and recovery.

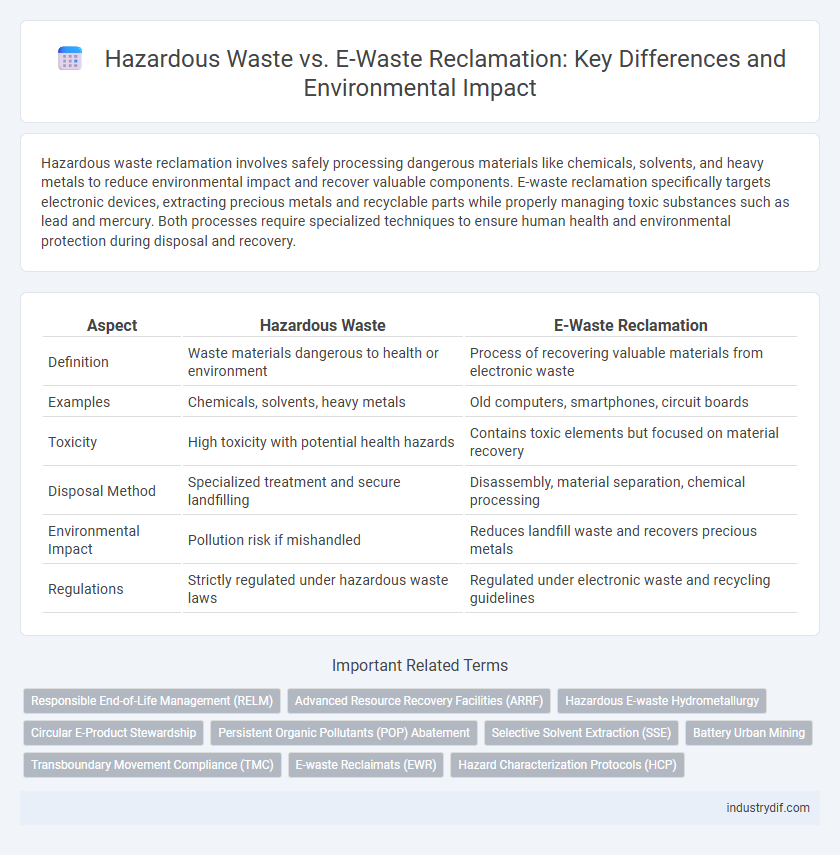

Table of Comparison

| Aspect | Hazardous Waste | E-Waste Reclamation |

|---|---|---|

| Definition | Waste materials dangerous to health or environment | Process of recovering valuable materials from electronic waste |

| Examples | Chemicals, solvents, heavy metals | Old computers, smartphones, circuit boards |

| Toxicity | High toxicity with potential health hazards | Contains toxic elements but focused on material recovery |

| Disposal Method | Specialized treatment and secure landfilling | Disassembly, material separation, chemical processing |

| Environmental Impact | Pollution risk if mishandled | Reduces landfill waste and recovers precious metals |

| Regulations | Strictly regulated under hazardous waste laws | Regulated under electronic waste and recycling guidelines |

Definition of Hazardous Waste and E-waste

Hazardous waste consists of materials that pose substantial threats to human health or the environment due to their chemical, physical, or biological properties, such as toxicity, flammability, or corrosiveness. E-waste, or electronic waste, refers to discarded electrical or electronic devices, including computers, smartphones, and televisions, which contain hazardous substances like lead, mercury, and cadmium requiring specialized reclamation processes. Proper reclamation of both hazardous waste and e-waste involves safe handling, treatment, and recovery methods to minimize environmental impact and recover valuable materials.

Key Differences between Hazardous Waste and E-waste

Hazardous waste includes materials like chemicals, solvents, and medical waste that pose significant health or environmental risks due to their toxic, corrosive, or reactive properties. E-waste specifically refers to discarded electronic devices such as computers, smartphones, and televisions, containing valuable metals like gold, silver, and palladium alongside harmful substances like lead and mercury. The key difference lies in hazardous waste's broad classification of dangerous substances across various industries, while e-waste reclamation targets the recovery of precious metals from electronics with specialized recycling processes.

Sources of Hazardous Waste and E-waste

Hazardous waste originates from industrial processes, chemical manufacturing, medical facilities, and automotive industries, containing toxic, corrosive, or flammable substances requiring specialized disposal. E-waste primarily comes from discarded electronic devices such as computers, smartphones, televisions, and household appliances, containing valuable metals and harmful components like lead and mercury. Efficient reclamation of both waste types demands targeted recovery methods to minimize environmental contamination and promote resource reuse.

Environmental Impact of Hazardous Waste

Hazardous waste poses significant environmental risks due to its toxic, corrosive, and reactive properties, which can contaminate soil, groundwater, and air if improperly managed. Unlike e-waste reclamation, which focuses on recovering valuable metals and reducing landfill volume, hazardous waste requires specialized treatment processes to neutralize harmful chemicals before disposal. Effective hazardous waste management is critical to prevent ecosystem damage, human health hazards, and long-term environmental pollution.

Environmental Risks of E-waste Mismanagement

E-waste mismanagement releases toxic substances such as lead, mercury, and cadmium into soil and water, causing severe environmental contamination and health risks. Unlike general hazardous waste, e-waste contains complex materials that break down slowly, leading to long-term pollutant accumulation and ecosystem damage. Improper disposal and informal recycling practices significantly increase greenhouse gas emissions and hazardous leachate, intensifying global environmental hazards.

Regulatory Framework for Hazardous Waste Management

The regulatory framework for hazardous waste management is governed by strict laws such as the Resource Conservation and Recovery Act (RCRA) in the United States, which mandates proper identification, handling, and disposal to minimize environmental contamination. In contrast, e-waste reclamation operates under overlapping regulations including the RCRA but also specific electronics recycling standards like the E-Cycle programs and the Basel Convention for international shipment controls. Compliance with these frameworks ensures that hazardous components in both waste streams are safely treated, recycled, or disposed of to prevent toxic exposure and ecosystem damage.

E-waste Reclamation Processes and Technologies

E-waste reclamation processes involve advanced technologies such as automated disassembly, mechanical shredding, and hydrometallurgical extraction to efficiently recover valuable metals like gold, silver, and copper. These methods reduce environmental hazards by safely separating toxic components, including lead, mercury, and cadmium, from electronic devices. Innovative techniques like bioleaching and plasma arc recycling enhance material recovery rates while minimizing energy consumption and pollution.

Challenges in Hazardous Waste Disposal

Hazardous waste disposal faces significant challenges due to the toxic and reactive nature of substances such as heavy metals, chemicals, and organic pollutants, which require specialized treatment to prevent environmental contamination. Unlike e-waste reclamation that primarily focuses on recovering valuable materials like gold, silver, and rare earth elements through controlled processes, hazardous waste demands stringent regulatory compliance and safe handling protocols to mitigate risks to human health and ecosystems. The complexity of hazardous waste management intensifies with the presence of mixed waste streams and the high costs associated with secure containment, transportation, and incineration or stabilization methods.

Economic Benefits of E-waste Reclamation

E-waste reclamation offers significant economic benefits by recovering valuable metals such as gold, silver, copper, and palladium, reducing the need for costly mining operations. Processing e-waste supports the creation of green jobs and stimulates innovation in recycling technologies, boosting local economies. Efficient recovery from e-waste also lowers disposal costs and mitigates environmental cleanup expenses associated with hazardous waste mismanagement.

Future Trends in Hazardous Waste and E-waste Reclamation

Emerging technologies in hazardous waste and e-waste reclamation emphasize advanced chemical stabilization and AI-driven sorting systems to enhance material recovery efficiency. Increased regulatory frameworks globally are driving innovation in sustainable recycling processes that reduce environmental impact and maximize resource reclamation. Integration of circular economy principles and investment in automated e-waste disassembly are set to transform future waste management strategies, improving both safety and economic viability.

Related Important Terms

Responsible End-of-Life Management (RELM)

Hazardous waste requires specialized containment and treatment protocols to prevent environmental contamination, while e-waste reclamation focuses on recovering valuable materials such as precious metals and rare earth elements through responsible end-of-life management (RELM) practices. Implementing RELM ensures the safe disposal and recycling of electronic components, minimizing toxic leachates and promoting sustainable resource reuse.

Advanced Resource Recovery Facilities (ARRF)

Advanced Resource Recovery Facilities (ARRF) specialize in processing both hazardous waste and e-waste using cutting-edge technologies that maximize material extraction while minimizing environmental impact. These facilities employ automated sorting, chemical treatments, and thermal processes to efficiently reclaim valuable metals, reduce toxic residues, and ensure safe disposal in compliance with regulatory standards.

Hazardous E-waste Hydrometallurgy

Hazardous e-waste hydrometallurgy involves using aqueous chemistry techniques to safely extract valuable metals such as gold, silver, copper, and rare earth elements from complex electronic waste streams while minimizing environmental toxicity. This method enhances resource recovery efficiency and reduces the hazardous impact compared to traditional pyrometallurgical processes commonly applied in hazardous waste and e-waste reclamation.

Circular E-Product Stewardship

Circular e-product stewardship emphasizes the reclamation of e-waste by recovering valuable materials like precious metals and rare earth elements, reducing hazardous waste impacts on the environment. This approach contrasts hazardous waste disposal by promoting sustainable lifecycle management through repair, reuse, and recycling, minimizing toxic exposure and resource depletion.

Persistent Organic Pollutants (POP) Abatement

Hazardous waste reclamation targets Persistent Organic Pollutants (POPs) through advanced chemical and thermal treatments to neutralize toxic compounds, while e-waste reclamation emphasizes the recovery of valuable metals alongside POP abatement techniques tailored to electronic components. Effective management of POPs in both hazardous and e-waste streams reduces environmental contamination and human health risks by decomposing or sequestering these persistent toxic substances.

Selective Solvent Extraction (SSE)

Selective Solvent Extraction (SSE) offers a highly efficient method in hazardous waste and e-waste reclamation by selectively separating valuable metals such as gold, silver, and palladium from complex waste streams. This process enhances metal recovery rates while minimizing secondary pollution, making it a critical technology in sustainable waste management and resource recovery.

Battery Urban Mining

Battery urban mining recovers critical metals such as lithium, cobalt, and nickel from hazardous e-waste, reducing environmental contamination and conserving finite natural resources. Advanced recycling technologies enable efficient extraction of valuable materials from spent batteries, promoting circular economy practices and minimizing hazardous waste disposal risks.

Transboundary Movement Compliance (TMC)

Hazardous waste and e-waste reclamation require strict adherence to Transboundary Movement Compliance (TMC) protocols under the Basel Convention to prevent illegal dumping and environmental contamination. Ensuring proper shipment documentation, notification procedures, and consent from importing countries is critical to maintaining regulatory compliance and promoting responsible recycling practices.

E-waste Reclaimats (EWR)

E-waste Reclaimers (EWR) specialize in recovering valuable materials like gold, silver, and copper from discarded electronic devices, significantly reducing environmental contamination compared to hazardous waste disposal. Their processes prioritize sustainable reclamation techniques that minimize toxic emissions and promote circular economy practices in the electronics industry.

Hazard Characterization Protocols (HCP)

Hazard Characterization Protocols (HCP) are essential in distinguishing between hazardous waste and e-waste reclamation by systematically evaluating chemical, physical, and toxicological properties to identify potential risks. These protocols enable regulatory compliance and safe treatment by classifying wastes based on hazard levels, facilitating proper handling, recycling, or disposal of materials like heavy metals, flame retardants, and persistent organic pollutants commonly found in e-waste.

Hazardous Waste vs E-waste Reclamation Infographic

industrydif.com

industrydif.com