Industrial waste comprises large volumes of byproducts from manufacturing processes, often containing hazardous materials requiring specialized disposal methods. Smart waste management employs advanced technologies such as IoT sensors and data analytics to optimize collection routes and reduce environmental impact. Integrating smart waste solutions in industrial settings enhances efficiency, lowers costs, and promotes sustainable waste handling practices.

Table of Comparison

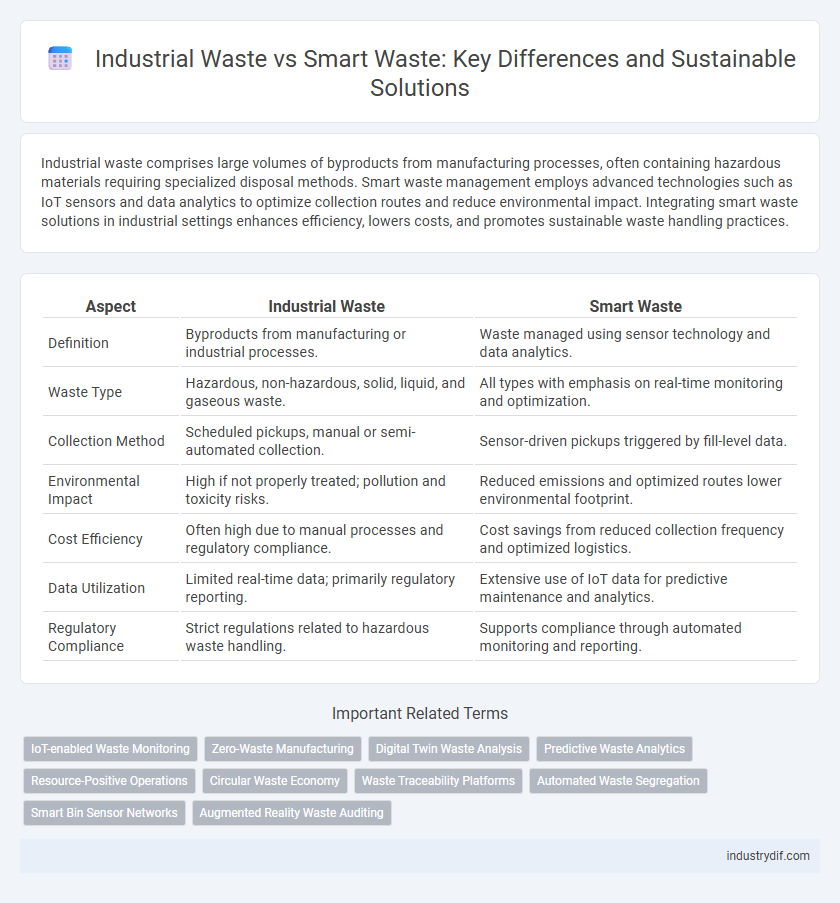

| Aspect | Industrial Waste | Smart Waste |

|---|---|---|

| Definition | Byproducts from manufacturing or industrial processes. | Waste managed using sensor technology and data analytics. |

| Waste Type | Hazardous, non-hazardous, solid, liquid, and gaseous waste. | All types with emphasis on real-time monitoring and optimization. |

| Collection Method | Scheduled pickups, manual or semi-automated collection. | Sensor-driven pickups triggered by fill-level data. |

| Environmental Impact | High if not properly treated; pollution and toxicity risks. | Reduced emissions and optimized routes lower environmental footprint. |

| Cost Efficiency | Often high due to manual processes and regulatory compliance. | Cost savings from reduced collection frequency and optimized logistics. |

| Data Utilization | Limited real-time data; primarily regulatory reporting. | Extensive use of IoT data for predictive maintenance and analytics. |

| Regulatory Compliance | Strict regulations related to hazardous waste handling. | Supports compliance through automated monitoring and reporting. |

Defining Industrial Waste and Smart Waste

Industrial waste comprises byproducts generated from manufacturing, chemical processing, and heavy industries, often containing hazardous materials such as heavy metals, solvents, and toxic chemicals. Smart waste utilizes Internet of Things (IoT) technology and sensors to optimize collection and processing, enabling real-time monitoring and efficient management of waste streams. Defining smart waste involves integrating data-driven solutions to reduce industrial waste impact, enhancing sustainability and resource recovery.

Key Differences Between Industrial Waste and Smart Waste

Industrial waste consists primarily of byproducts from manufacturing processes, including hazardous chemicals, heavy metals, and non-biodegradable materials, requiring specialized disposal methods. Smart waste refers to waste materials managed using advanced technologies such as IoT sensors, AI-driven analytics, and automated collection systems to optimize efficiency and reduce environmental impact. Key differences lie in industrial waste's traditional physical composition versus smart waste's integration with digital management systems enabling real-time monitoring and data-driven decision-making.

Types and Sources of Industrial Waste

Industrial waste primarily includes manufacturing byproducts such as chemicals, heavy metals, plastics, solvents, and scrap materials generated by factories, power plants, and refineries. Common sources of industrial waste encompass sectors like textile production, metal processing, chemical manufacturing, and food processing industries, each producing distinctive waste types requiring specialized handling. Smart waste management integrates technology to monitor and optimize the disposal of these hazardous and non-hazardous wastes, reducing environmental impact and improving resource recovery.

Technologies Driving Smart Waste Management

Industrial waste management relies heavily on traditional methods such as landfilling and incineration, often leading to environmental pollution and resource depletion. Smart waste management incorporates advanced technologies like IoT sensors, machine learning, and data analytics to optimize waste collection, sorting, and recycling processes. These innovations enable real-time monitoring, predictive maintenance, and efficient resource utilization, significantly reducing the ecological footprint of waste management operations.

Environmental Impact: Industrial vs Smart Waste

Industrial waste often contains hazardous materials that contribute significantly to soil, water, and air pollution, posing severe health risks and environmental degradation. Smart waste management employs advanced technologies like IoT sensors and data analytics to optimize waste collection, reduce landfill use, and minimize carbon emissions. The shift from traditional industrial waste disposal to smart waste systems enhances sustainability by promoting resource recovery and reducing environmental impact.

Regulatory Frameworks for Waste Management

Regulatory frameworks for industrial waste management mandate strict compliance with hazardous material handling, disposal procedures, and emission limits, enforced by agencies such as the EPA and OSHA. Smart waste management incorporates IoT-enabled monitoring systems and data analytics to enhance regulatory adherence, providing real-time reporting and automated compliance alerts. Integration of advanced technologies within legal structures promotes sustainable practices, reduces environmental impact, and ensures efficient resource recovery.

Smart Waste Solutions in Industrial Settings

Smart waste solutions in industrial settings leverage IoT sensors and AI analytics to optimize waste collection and reduce operational costs. These technologies enable real-time monitoring of industrial waste levels, ensuring timely disposal and minimizing environmental impact. Implementing smart waste management systems enhances resource efficiency and supports sustainable industrial practices.

Economic Benefits of Smart Waste Over Traditional Methods

Smart waste management systems reduce operational costs by optimizing collection routes and minimizing fuel consumption, leading to significant economic savings compared to traditional industrial waste methods. Real-time data analytics enable precise waste sorting and processing, increasing recycling rates and reducing landfill fees. Enhanced resource efficiency in smart waste solutions drives lower labor expenses and improves revenue through the recovery of valuable materials.

Challenges in Transitioning from Industrial to Smart Waste

Transitioning from industrial waste management to smart waste systems faces challenges such as integrating IoT-enabled sensors with legacy infrastructure and addressing data privacy concerns. High initial investment costs and the need for skilled personnel to operate advanced analytics platforms pose additional barriers. Overcoming regulatory inconsistencies and ensuring real-time data accuracy remain critical to achieving efficient smart waste solutions.

Future Trends in Waste Management: Smart Systems vs Conventional Methods

Industrial waste management traditionally relies on manual sorting and landfilling, resulting in inefficiencies and environmental hazards. Smart waste systems integrate IoT sensors and AI analytics to optimize collection routes, reduce operational costs, and enhance recycling rates. Future trends emphasize the shift towards data-driven solutions that enable real-time monitoring and predictive maintenance, surpassing the limitations of conventional methods.

Related Important Terms

IoT-enabled Waste Monitoring

Industrial waste typically consists of large volumes of hazardous byproducts generated by manufacturing processes, posing significant environmental and health risks if not properly managed. Smart waste solutions leverage IoT-enabled waste monitoring systems equipped with sensors and real-time data analytics to optimize collection routes, reduce overflow, and enhance recycling efficiency, transforming traditional waste management into a more sustainable and cost-effective practice.

Zero-Waste Manufacturing

Zero-waste manufacturing aims to eliminate industrial waste by integrating smart waste technologies that optimize resource efficiency and material recovery throughout production processes. Implementing IoT sensors and AI analytics enables real-time monitoring and precise waste segregation, significantly reducing landfill contributions and promoting circular economy principles within industrial settings.

Digital Twin Waste Analysis

Industrial waste management traditionally relies on manual monitoring and periodic assessments, often leading to inefficiencies and increased environmental impact. Digital twin waste analysis leverages real-time data and advanced simulations to optimize smart waste strategies, enhancing resource recovery and minimizing disposal costs.

Predictive Waste Analytics

Industrial waste management faces challenges due to unpredictable waste volumes and hazardous materials, whereas smart waste systems leverage predictive waste analytics to optimize collection schedules and reduce operational costs. Predictive models use real-time data from IoT sensors to forecast waste generation patterns, improving resource allocation and minimizing environmental impacts.

Resource-Positive Operations

Industrial waste typically involves large volumes of hazardous and non-recyclable materials generated by manufacturing processes, posing significant environmental challenges due to inefficient disposal and limited reuse strategies. Smart waste management leverages data analytics, IoT sensors, and AI-driven optimization to transform waste streams into resource-positive operations, enhancing recycling rates, reducing landfill dependency, and promoting a circular economy.

Circular Waste Economy

Industrial waste management traditionally involves large-scale disposal methods, whereas smart waste systems employ IoT sensors and data analytics to optimize recycling processes, significantly enhancing resource recovery efficiency. Implementing a circular waste economy leverages smart waste technologies to transform industrial byproducts into valuable materials, reducing landfill usage and conserving raw resources.

Waste Traceability Platforms

Industrial waste management often lacks transparency and real-time monitoring, leading to inefficient disposal and environmental risks, whereas smart waste traceability platforms utilize IoT sensors and blockchain technology for precise tracking, ensuring accountability and compliance from waste generation to final processing. These platforms enhance data accuracy and operational efficiency by providing stakeholders with actionable insights and automated reporting throughout the waste management lifecycle.

Automated Waste Segregation

Automated waste segregation in industrial waste management leverages advanced sensors and AI to accurately classify materials, reducing contamination and enhancing recycling efficiency. Smart waste systems integrate IoT technologies to monitor waste streams in real-time, optimizing collection routes and minimizing operational costs while promoting sustainable waste handling.

Smart Bin Sensor Networks

Smart bin sensor networks revolutionize industrial waste management by enabling real-time monitoring of waste levels, optimizing collection routes, and reducing overflow incidents. These IoT-enabled systems enhance operational efficiency and environmental sustainability compared to traditional industrial waste disposal methods.

Augmented Reality Waste Auditing

Industrial waste management often faces challenges in accurately tracking and sorting hazardous materials, leading to inefficient disposal and environmental risks. Smart waste solutions leverage augmented reality waste auditing, enhancing real-time data visualization and analysis for precise waste categorization and improved regulatory compliance.

Industrial Waste vs Smart Waste Infographic

industrydif.com

industrydif.com