Incineration reduces waste volume by burning materials at high temperatures, but it can release harmful emissions if not properly controlled. Waste-to-energy (WTE) combines incineration with energy recovery, converting waste into renewable electricity and heat while minimizing environmental impact through advanced pollution controls. Both methods address landfill overflow, but WTE offers a sustainable solution by turning waste into valuable resources.

Table of Comparison

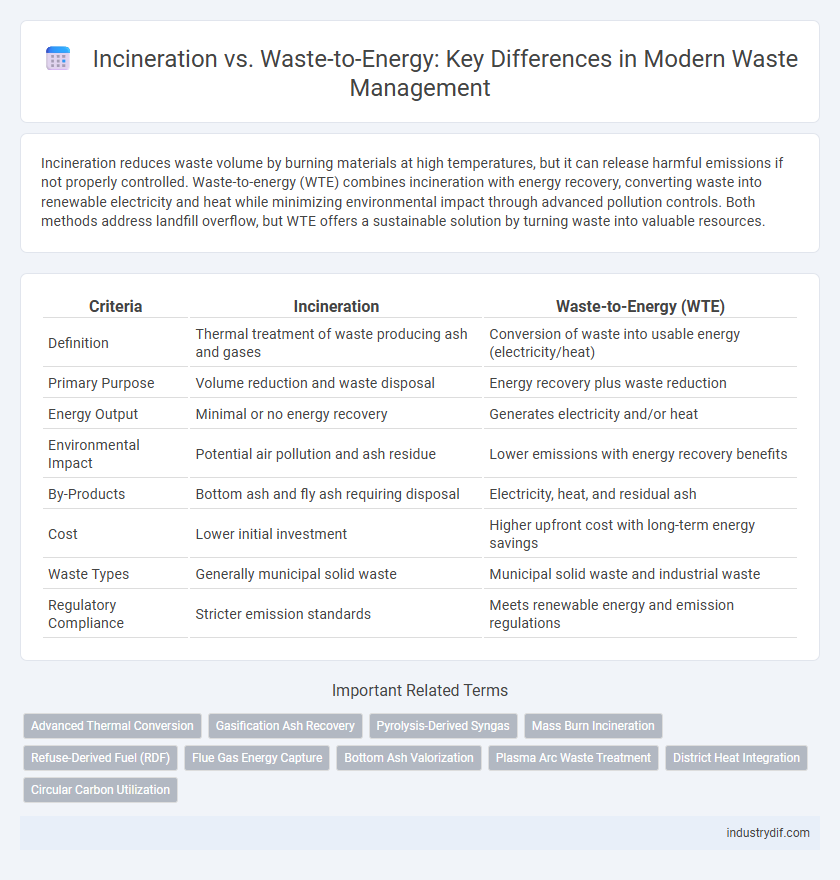

| Criteria | Incineration | Waste-to-Energy (WTE) |

|---|---|---|

| Definition | Thermal treatment of waste producing ash and gases | Conversion of waste into usable energy (electricity/heat) |

| Primary Purpose | Volume reduction and waste disposal | Energy recovery plus waste reduction |

| Energy Output | Minimal or no energy recovery | Generates electricity and/or heat |

| Environmental Impact | Potential air pollution and ash residue | Lower emissions with energy recovery benefits |

| By-Products | Bottom ash and fly ash requiring disposal | Electricity, heat, and residual ash |

| Cost | Lower initial investment | Higher upfront cost with long-term energy savings |

| Waste Types | Generally municipal solid waste | Municipal solid waste and industrial waste |

| Regulatory Compliance | Stricter emission standards | Meets renewable energy and emission regulations |

Incineration and Waste-to-Energy: Key Industry Definitions

Incineration refers to the process of burning waste materials at high temperatures to reduce volume and convert waste into ash, flue gas, and heat. Waste-to-Energy (WTE) involves incineration or other thermal treatments that not only reduce waste volume but also capture energy in the form of electricity or heat for use in power grids or district heating systems. Key industry definitions distinguish incineration as a simple disposal method, while Waste-to-Energy emphasizes energy recovery and sustainable waste management solutions.

Historical Evolution of Waste Disposal Technologies

Incineration, which dates back to the late 19th century, initially served as a primary method for reducing municipal solid waste volume through high-temperature combustion. Waste-to-energy (WTE) technologies evolved in the mid-20th century, integrating waste incineration with energy recovery systems to generate electricity and heat, enhancing resource efficiency. Advances in emission control and combustion technology have significantly improved environmental performance, marking a transition from simple waste disposal to sustainable energy conversion.

How Incineration Works: Process Overview

Incineration involves the combustion of waste materials at high temperatures, reducing volume and converting waste into ash, flue gas, and heat. Waste-to-energy plants utilize this heat to generate steam, which drives turbines to produce electricity, integrating waste disposal with energy recovery. Key components include waste feeding systems, combustion chambers, air pollution control devices, and energy recovery units, ensuring efficient processing and emission control.

Understanding Modern Waste-to-Energy Systems

Modern waste-to-energy (WtE) systems optimize waste incineration by converting municipal solid waste into electricity and heat through advanced combustion technologies. These systems incorporate air pollution control devices, such as scrubbers and filters, to minimize emissions of dioxins, furans, and particulate matter, ensuring compliance with environmental regulations. Enhanced energy recovery efficiency and resource conservation in WtE plants contribute to reducing landfill use and lowering greenhouse gas emissions compared to traditional incineration methods.

Environmental Impacts: Incineration vs Waste-to-Energy

Incineration releases significant amounts of CO2 and toxic emissions such as dioxins and furans, contributing to air pollution and health risks. Waste-to-Energy (WTE) facilities incorporate advanced pollution control technologies that reduce emissions, capture energy, and lower landfill dependence. The Environmental Protection Agency (EPA) reports that modern WTE plants reduce greenhouse gas emissions by offsetting fossil fuel energy production compared to traditional incineration methods.

Energy Recovery Efficiency: A Comparative Analysis

Incineration and waste-to-energy (WTE) technologies differ significantly in energy recovery efficiency, with WTE plants typically achieving 20-30% higher efficiency through advanced combustion and heat recovery systems. Modern waste-to-energy facilities utilize combined heat and power (CHP) techniques to convert municipal solid waste into electricity and thermal energy, maximizing energy output per ton of waste processed. In contrast, conventional incineration primarily reduces waste volume but recovers less usable energy, resulting in lower overall system efficiency.

Air Emissions and Pollution Controls in Both Processes

Incineration releases significant air pollutants such as dioxins, furans, and particulate matter, requiring advanced filtration systems like electrostatic precipitators and fabric filters to mitigate environmental impact. Waste-to-Energy (WTE) plants incorporate comprehensive pollution controls including scrubbers, selective catalytic reduction (SCR) systems, and continuous emissions monitoring to substantially reduce nitrogen oxides (NOx), sulfur dioxide (SO2), and heavy metals. Both methods demand stringent regulatory compliance under frameworks like the Clean Air Act to minimize harmful air emissions and protect public health.

Economic Considerations: Cost and Revenue Streams

Incineration involves straightforward combustion of waste with lower upfront capital costs but limited revenue generation, primarily from tipping fees. Waste-to-Energy (WtE) facilities, while requiring higher initial investment due to advanced technology for energy recovery and emissions control, generate diversified revenue streams including electricity sales, heat distribution, and byproduct utilization such as ash for cement production. Economic viability improves in WtE projects through long-term energy contracts and government incentives promoting renewable energy, offsetting operational expenses over time.

Global Regulations and Policy Trends

Global regulations increasingly favor waste-to-energy (WTE) over traditional incineration due to stricter emissions standards set by the European Union's Waste Framework Directive and the United States EPA's Clean Air Act. Policy trends emphasize circular economy principles, promoting WTE technologies that recover energy while minimizing environmental impact and supporting carbon reduction targets outlined in the Paris Agreement. Countries like Japan and South Korea implement stringent permits and incentives for advanced WTE plants, reflecting a global shift towards sustainable waste management solutions.

Future Innovations in Thermal Waste Treatment

Emerging advancements in thermal waste treatment include more efficient waste-to-energy (WTE) systems integrating plasma gasification and advanced flue gas cleaning technologies to minimize emissions. Future innovations aim to optimize incineration processes by enhancing energy recovery rates and reducing toxic byproducts through catalysts and improved combustion controls. These developments promise to elevate sustainability standards by combining maximized energy extraction with stringent environmental compliance.

Related Important Terms

Advanced Thermal Conversion

Advanced Thermal Conversion techniques, such as pyrolysis and gasification, offer more efficient and environmentally friendly alternatives to traditional incineration by converting waste into valuable energy and reducing harmful emissions. These methods optimize energy recovery while minimizing the production of toxic residues and greenhouse gases compared to conventional Waste-to-Energy incineration processes.

Gasification Ash Recovery

Gasification ash recovery offers higher efficiency in extracting valuable metals and minerals compared to traditional incineration, reducing landfill waste and enabling resource circularity. Its controlled, lower-temperature process minimizes toxic emissions, enhancing environmental sustainability while producing syngas for energy generation.

Pyrolysis-Derived Syngas

Pyrolysis-derived syngas offers a cleaner alternative to traditional incineration by producing fewer pollutants and enabling higher energy recovery rates through gasification processes. Its composition, rich in hydrogen and carbon monoxide, enhances efficiency in waste-to-energy conversion compared to direct combustion methods.

Mass Burn Incineration

Mass burn incineration involves the direct combustion of municipal solid waste without prior sorting, resulting in significant volume reduction but higher emissions compared to advanced waste-to-energy technologies that incorporate energy recovery systems. Waste-to-energy processes utilize mass burn incineration combined with energy capture, producing electricity and heat while minimizing environmental impact through emissions control and efficient waste conversion.

Refuse-Derived Fuel (RDF)

Refuse-Derived Fuel (RDF) enhances waste-to-energy processes by converting sorted municipal solid waste into a high-energy fuel, offering a cleaner and more efficient alternative to traditional incineration. Utilizing RDF reduces landfill dependency and lowers greenhouse gas emissions by maximizing energy recovery from combustible waste materials.

Flue Gas Energy Capture

Incineration primarily focuses on reducing waste volume through combustion, releasing heat energy that is often lost or minimally captured. Waste-to-energy processes optimize flue gas energy capture by integrating advanced heat recovery systems and gas cleaning technologies, converting emissions into usable energy forms such as steam or electricity, thereby enhancing overall energy efficiency and reducing environmental impact.

Bottom Ash Valorization

Incineration produces bottom ash that contains recoverable metals and minerals, making its valorization crucial for reducing landfill dependency and enhancing resource recovery. Waste-to-energy plants optimize bottom ash processing to extract valuable materials while minimizing environmental impact and maximizing energy output efficiency.

Plasma Arc Waste Treatment

Plasma Arc Waste Treatment employs extremely high temperatures generated by plasma torches to convert waste into syngas and inert slag, offering a cleaner alternative to traditional incineration by significantly reducing harmful emissions and volume of residual waste. This technology enhances waste-to-energy efficiency by producing a higher calorific value gas, making it a sustainable option for energy recovery and minimizing environmental impact compared to conventional incineration methods.

District Heat Integration

Incineration and waste-to-energy (WTE) plants both convert municipal solid waste into usable heat but differ significantly in district heat integration efficiency; WTE facilities optimize energy recovery by coupling advanced combustion with combined heat and power (CHP) systems to supply consistent thermal energy to urban heating networks. District heating integration in waste-to-energy plants reduces fossil fuel dependency, cuts greenhouse gas emissions, and promotes sustainable urban energy cycles by distributing heat directly through insulated pipelines to residential and commercial buildings.

Circular Carbon Utilization

Incineration primarily reduces waste volume through combustion but often emits significant carbon dioxide without recovering energy, limiting its role in circular carbon utilization. Waste-to-Energy technologies convert waste into usable energy while capturing and recycling carbon emissions, enhancing sustainability by integrating carbon recovery into the circular economy.

Incineration vs Waste-to-Energy Infographic

industrydif.com

industrydif.com