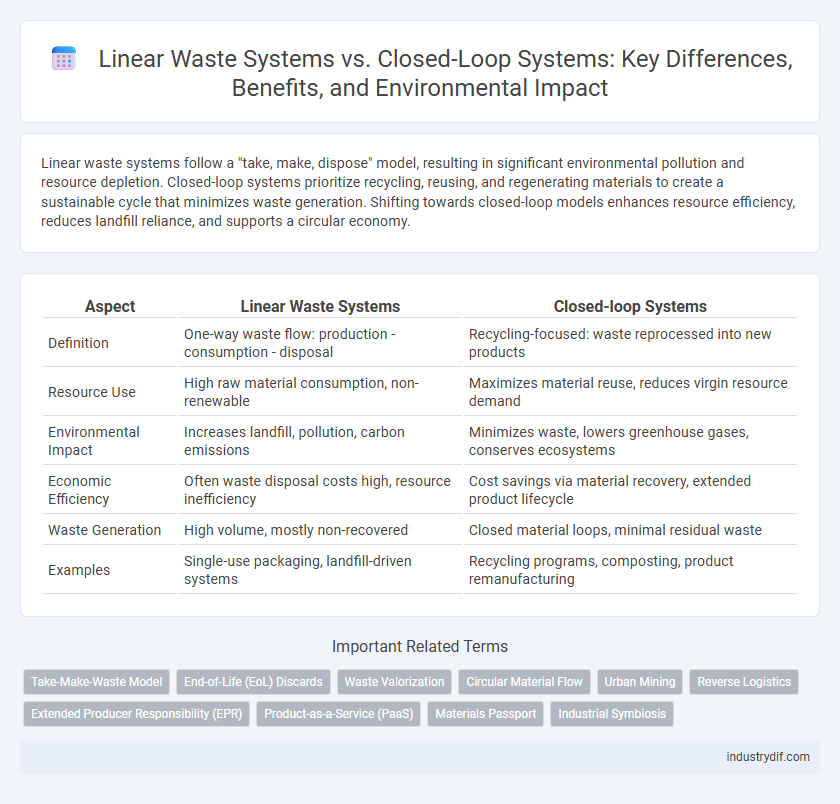

Linear waste systems follow a "take, make, dispose" model, resulting in significant environmental pollution and resource depletion. Closed-loop systems prioritize recycling, reusing, and regenerating materials to create a sustainable cycle that minimizes waste generation. Shifting towards closed-loop models enhances resource efficiency, reduces landfill reliance, and supports a circular economy.

Table of Comparison

| Aspect | Linear Waste Systems | Closed-loop Systems |

|---|---|---|

| Definition | One-way waste flow: production - consumption - disposal | Recycling-focused: waste reprocessed into new products |

| Resource Use | High raw material consumption, non-renewable | Maximizes material reuse, reduces virgin resource demand |

| Environmental Impact | Increases landfill, pollution, carbon emissions | Minimizes waste, lowers greenhouse gases, conserves ecosystems |

| Economic Efficiency | Often waste disposal costs high, resource inefficiency | Cost savings via material recovery, extended product lifecycle |

| Waste Generation | High volume, mostly non-recovered | Closed material loops, minimal residual waste |

| Examples | Single-use packaging, landfill-driven systems | Recycling programs, composting, product remanufacturing |

Understanding Linear Waste Systems

Linear waste systems follow a straightforward process of production, consumption, and disposal, generating significant amounts of landfill and pollution. These systems rely heavily on finite natural resources and lack mechanisms for recycling or reuse, leading to substantial environmental degradation. Understanding the inefficiencies of linear waste systems highlights the urgent need for transitioning to sustainable models like closed-loop systems.

Defining Closed-Loop Waste Systems

Closed-loop waste systems prioritize the continuous reuse and recycling of materials, minimizing waste generation by transforming end-of-life products back into raw materials for production. Unlike linear waste systems, which follow a take-use-dispose model leading to resource depletion and environmental harm, closed-loop systems emphasize sustainability through circular economy principles. These systems reduce landfill dependency and resource extraction, driving efficiency by maintaining material value within the production cycle.

Key Differences Between Linear and Closed-Loop Models

Linear waste systems operate on a take-make-dispose model, leading to significant environmental pollution and resource depletion due to the lack of recycling or reuse. Closed-loop systems emphasize circularity by designing products for durability, reuse, and recycling, significantly reducing landfill waste and conserving raw materials. The key difference lies in resource management: linear systems rely on constant extraction, whereas closed-loop systems prioritize sustainability through continuous material recovery.

Environmental Impacts of Linear Waste Systems

Linear waste systems generate significant environmental degradation due to their reliance on a take-make-dispose model, leading to resource depletion, increased greenhouse gas emissions, and persistent landfill accumulation. The continuous extraction and disposal cycle in linear systems exacerbates pollution in air, soil, and water, contributing to biodiversity loss and ecosystem disruption. Inefficient waste management in linear systems results in substantial carbon footprints and hinders efforts toward sustainable resource utilization.

Resource Efficiency in Closed-Loop Approaches

Closed-loop waste systems significantly enhance resource efficiency by promoting the reuse, recycling, and recovery of materials, minimizing the extraction of virgin resources. Unlike linear waste models that follow a take-make-dispose pattern, closed-loop approaches reduce environmental impact and waste generation through circular material flows. Implementing closed-loop systems leads to sustainable consumption, cost savings, and reduced landfill dependency by maximizing the lifecycle of products and materials.

Economic Implications of Waste Management Systems

Linear waste systems generate higher long-term costs due to resource depletion and increased landfill expenses, while closed-loop systems offer economic benefits by promoting resource efficiency and reducing material costs through recycling and reuse. Investing in circular economy models fosters job creation in recycling industries and lowers environmental remediation costs. Closed-loop waste management improves sustainability, leading to increased profitability and reduced financial risk for businesses and municipalities.

Technological Innovations in Closed-Loop Systems

Closed-loop systems leverage advanced technologies such as AI-driven sorting, chemical recycling, and bioconversion to maximize resource recovery and minimize waste output. Innovations in sensor-based material identification and automated processing enable higher purity levels in recycled materials, enhancing their value and usability. These technological advancements facilitate sustainable waste management by closing the material loop and significantly reducing dependency on virgin resources.

Regulatory Drivers for Circular Waste Solutions

Regulatory drivers for circular waste solutions emphasize stringent landfill reduction targets and extended producer responsibility (EPR) policies to shift from linear waste systems toward closed-loop models. Governments enforce regulations mandating recycling quotas, biodegradable material usage, and transparent waste tracking to promote resource recovery and minimize landfill dependency. Compliance with international agreements like the EU Circular Economy Action Plan accelerates adoption of closed-loop waste management, ensuring materials are continuously reused and environmental impact is minimized.

Industry Case Studies: Linear vs Closed-Loop Successes

Industry case studies highlight significant efficiency gains and cost reductions achieved by companies adopting closed-loop systems, particularly in the electronics and automotive sectors. Linear waste systems, exemplified by traditional manufacturing plants, generate high volumes of landfill waste and raw material depletion, as seen in the fast-fashion industry. Closed-loop models enable firms like Siemens and Adidas to reclaim materials, reduce resource dependency, and minimize environmental impact through circular design and recycling technologies.

Future Trends in Sustainable Waste Systems

Linear waste systems, characterized by a take-make-dispose model, are increasingly unsustainable due to resource depletion and environmental pollution. Closed-loop systems prioritize recycling, reuse, and regeneration to minimize waste and maximize resource efficiency, aligning with circular economy principles. Future trends emphasize integrating advanced technologies like AI-driven sorting, biodegradable materials, and policy frameworks promoting zero waste, driving a transition toward sustainable waste management globally.

Related Important Terms

Take-Make-Waste Model

The Take-Make-Waste model in linear waste systems generates significant environmental strain by extracting raw materials, manufacturing products, and disposing of waste without recycling or reuse. Closed-loop systems minimize waste by designing products for durability, reuse, and recyclability, promoting sustainable resource management and reducing landfill dependency.

End-of-Life (EoL) Discards

Linear waste systems generate significant End-of-Life (EoL) discards by disposing products after single-use, contributing to environmental pollution and resource depletion. Closed-loop systems minimize EoL discards through recycling, remanufacturing, and reuse processes, enhancing sustainability and conserving raw materials.

Waste Valorization

Linear waste systems prioritize disposal and resource extraction, often resulting in significant environmental impact and resource depletion. Closed-loop systems emphasize waste valorization by recycling and repurposing materials, transforming waste into valuable resources to achieve sustainability and reduce landfill dependency.

Circular Material Flow

Linear waste systems follow a take-make-dispose model resulting in resource depletion and increased landfill accumulation, whereas closed-loop systems promote circular material flow by reusing, recycling, and regenerating materials to minimize waste and conserve resources. Implementing closed-loop systems enhances sustainability through continuous material circulation, reducing environmental impact and fostering economic resilience.

Urban Mining

Linear waste systems rely heavily on raw material extraction and discard, leading to significant resource depletion and environmental degradation, whereas closed-loop systems prioritize urban mining by recovering valuable materials from post-consumer waste to reintegrate into production cycles, thereby reducing landfill dependency and conserving finite resources. Urban mining facilitates sustainable resource management in closed-loop systems by extracting metals and rare earth elements from electronic waste, construction debris, and other urban refuse streams to minimize the demand for virgin materials.

Reverse Logistics

Reverse logistics plays a critical role in closed-loop waste systems by enabling the collection, refurbishment, and recycling of products, significantly reducing landfill dependency. In contrast, linear waste systems primarily rely on forward logistics for disposal, leading to higher waste generation and resource depletion.

Extended Producer Responsibility (EPR)

Extended Producer Responsibility (EPR) policies shift the accountability for waste management from municipalities to producers, incentivizing the design of products within closed-loop systems that prioritize reuse and recycling over linear waste approaches. By mandating producers to manage the end-of-life impact of their products, EPR drives the transition from linear waste systems--characterized by "take-make-dispose" patterns--to sustainable closed-loop systems that reduce environmental impact and improve resource efficiency.

Product-as-a-Service (PaaS)

Linear waste systems generate significant environmental burden by promoting single-use products and disposing of materials after consumption, whereas closed-loop systems minimize waste by designing products for reuse, recycling, and durability. Product-as-a-Service (PaaS) models enhance closed-loop systems by shifting ownership to providers who maintain, refurbish, and recycle products, fostering resource efficiency and reducing landfill waste.

Materials Passport

Materials Passports enable Closed-loop Systems by providing detailed information on the composition and recyclability of products, facilitating efficient recovery and reuse of materials. In contrast, Linear Waste Systems lack this transparency, leading to increased waste generation and resource depletion.

Industrial Symbiosis

Linear waste systems generate significant industrial byproducts that often become environmental liabilities, whereas closed-loop systems leverage industrial symbiosis to transform waste into valuable inputs, enhancing resource efficiency and reducing landfill dependency. Industrial symbiosis facilitates the exchange of materials, energy, and water among interconnected industries, driving sustainable circular economies and minimizing ecological footprints.

Linear Waste Systems vs Closed-loop Systems Infographic

industrydif.com

industrydif.com