Industrial waste often consists of hazardous byproducts generated from manufacturing processes that require proper disposal to prevent environmental harm. Industrial symbiosis promotes the collaborative reuse of waste materials between industries, turning byproducts into valuable inputs and reducing overall waste production. This approach enhances resource efficiency, lowers costs, and minimizes the environmental footprint of industrial activities.

Table of Comparison

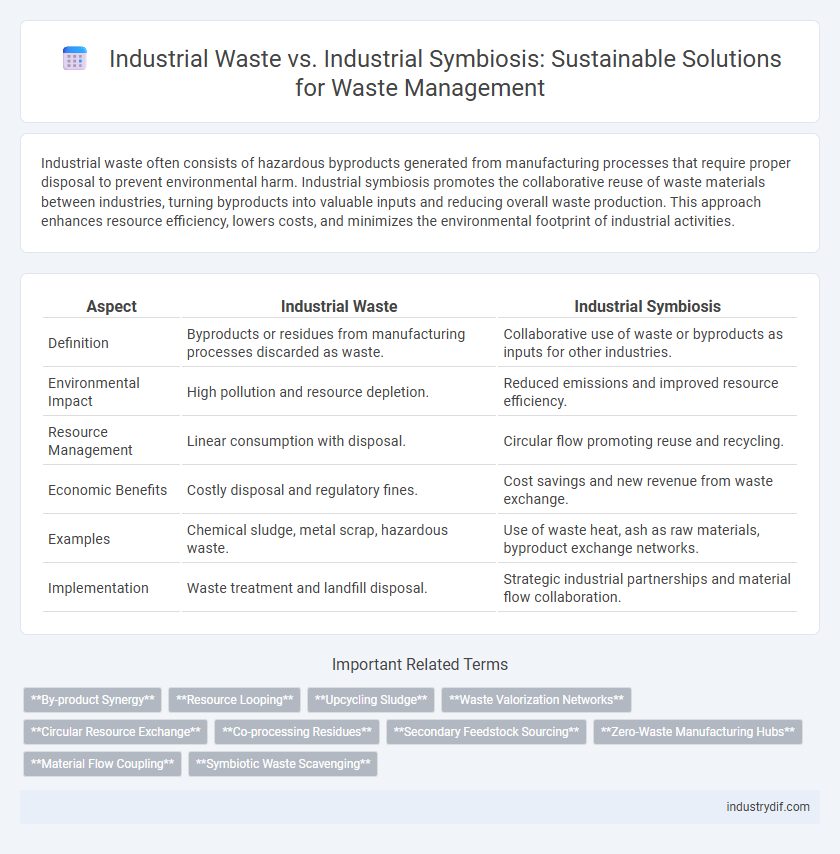

| Aspect | Industrial Waste | Industrial Symbiosis |

|---|---|---|

| Definition | Byproducts or residues from manufacturing processes discarded as waste. | Collaborative use of waste or byproducts as inputs for other industries. |

| Environmental Impact | High pollution and resource depletion. | Reduced emissions and improved resource efficiency. |

| Resource Management | Linear consumption with disposal. | Circular flow promoting reuse and recycling. |

| Economic Benefits | Costly disposal and regulatory fines. | Cost savings and new revenue from waste exchange. |

| Examples | Chemical sludge, metal scrap, hazardous waste. | Use of waste heat, ash as raw materials, byproduct exchange networks. |

| Implementation | Waste treatment and landfill disposal. | Strategic industrial partnerships and material flow collaboration. |

Defining Industrial Waste

Industrial waste refers to the by-products generated from manufacturing processes, including hazardous chemicals, scrap metals, and toxic substances that require proper disposal or treatment to prevent environmental contamination. Unlike general waste, industrial waste demands specialized handling due to its potential to harm ecosystems and human health through air, water, and soil pollution. Understanding the characteristics and sources of industrial waste is essential for developing effective waste management strategies and exploring industrial symbiosis opportunities where one industry's waste becomes another's raw material.

Overview of Industrial Symbiosis

Industrial symbiosis transforms traditional industrial waste streams into valuable resources by promoting collaboration between manufacturing facilities, leading to reduced landfill use and lower environmental impact. This process optimizes resource efficiency through the exchange of energy, materials, and by-products, fostering circular economy principles within industrial parks. Emphasizing system-wide integration, industrial symbiosis enhances waste valorization, reduces operational costs, and supports sustainable industrial development.

Key Differences Between Waste and Symbiosis

Industrial waste involves the disposal of byproducts generated from manufacturing processes, often requiring treatment to minimize environmental harm. Industrial symbiosis, by contrast, emphasizes resource sharing and the reuse of waste materials as inputs for other processes, promoting circular economy practices. Key differences lie in waste management's focus on elimination and containment versus symbiosis' integration of waste streams to enhance sustainability and reduce raw material consumption.

Types of Industrial Waste

Industrial waste includes hazardous substances such as heavy metals, chemical solvents, and toxic sludges generated from manufacturing processes, posing significant environmental threats. Industrial symbiosis transforms waste types like heat, wastewater, and by-products into valuable resources by enabling material and energy exchanges between industries. This approach reduces landfill disposal and promotes circular economy principles by converting diverse industrial waste streams into inputs for other processes.

Principles Behind Industrial Symbiosis

Industrial Symbiosis relies on principles of resource efficiency, collaboration, and waste valorization to transform traditional industrial waste streams into valuable secondary materials, reducing environmental impact and operational costs. Unlike conventional industrial waste management that emphasizes disposal, Industrial Symbiosis promotes the exchange of by-products, energy, and information among different industries to close material loops and optimize resource use. This approach aligns with circular economy objectives by fostering sustainable production patterns and minimizing raw material extraction.

Economic Impact of Industrial Waste

Industrial waste generates significant economic costs, including disposal fees, regulatory compliance expenses, and potential environmental fines, which can reduce a company's profitability. Industrial symbiosis transforms waste streams into valuable resources through inter-company collaborations, enhancing resource efficiency and reducing raw material expenses. This circular approach promotes economic growth by minimizing waste management costs and creating new revenue opportunities from by-products.

Benefits of Industrial Symbiosis

Industrial symbiosis transforms industrial waste by enabling the reuse of by-products as raw materials in other processes, significantly reducing overall waste generation. This approach decreases disposal costs and environmental pollution while enhancing resource efficiency and fostering sustainable industrial growth. Industries engaged in symbiosis benefit from reduced energy consumption and improved economic performance through shared resources and cooperative innovation.

Case Studies: Waste Management vs Symbiosis

Industrial waste management typically involves the removal, treatment, and disposal of byproducts generated by manufacturing processes, often leading to significant environmental impact and high operational costs. In contrast, industrial symbiosis emphasizes the collaborative exchange of resources, where waste from one industry becomes raw material for another, exemplified by case studies such as the Kalundborg Eco-Industrial Park in Denmark, which demonstrates substantial reductions in landfill use and greenhouse gas emissions. These symbiotic networks optimize resource efficiency, lower environmental footprints, and generate economic benefits by transforming waste into valuable inputs, reshaping traditional waste management paradigms.

Environmental Implications

Industrial waste often contains hazardous substances that can pollute soil, water, and air, leading to long-term environmental degradation and health risks. Industrial symbiosis reduces these environmental impacts by promoting resource efficiency, waste minimization, and the reuse of by-products among interconnected industries. This collaborative approach significantly lowers greenhouse gas emissions and conserves natural resources compared to traditional waste disposal methods.

Future Trends in Industrial Resource Circulation

Future trends in industrial resource circulation emphasize the shift from traditional industrial waste disposal towards advanced industrial symbiosis, where by-products and waste materials from one process become valuable inputs for another. This transition fosters sustainable resource efficiency, reduces environmental impact, and drives circular economy initiatives within manufacturing sectors. Emerging technologies such as AI-driven waste tracking and blockchain for transparent material exchanges are poised to accelerate these symbiotic industrial networks globally.

Related Important Terms

By-product Synergy

Industrial waste often consists of excess materials discarded after production, whereas industrial symbiosis leverages by-product synergy by transforming these wastes into valuable inputs for other processes, reducing environmental impact and resource consumption. This approach enhances circular economy practices by fostering collaboration between industries to optimize material flows and minimize waste generation.

Resource Looping

Industrial waste often leads to resource depletion and environmental pollution, whereas industrial symbiosis promotes resource looping by enabling waste from one process to become input for another, thereby minimizing raw material consumption and reducing landfill use. This circular approach enhances sustainability by optimizing material flows and closing resource loops within industrial ecosystems.

Upcycling Sludge

Industrial waste, particularly sludge, poses significant environmental challenges due to its volume and toxicity, but industrial symbiosis offers innovative solutions by transforming sludge into valuable materials through upcycling processes. Upcycling sludge in industrial symbiosis reduces landfill use and greenhouse gas emissions while creating secondary raw materials for construction, agriculture, and energy sectors, enhancing resource efficiency and circular economy initiatives.

Waste Valorization Networks

Industrial waste management benefits significantly from industrial symbiosis through waste valorization networks, where by-products of one industry serve as raw materials for another, reducing landfill dependency and conserving resources. These interconnected systems enhance sustainability by promoting circular economy principles, optimizing resource efficiency, and minimizing environmental footprints associated with traditional industrial waste disposal.

Circular Resource Exchange

Industrial waste generation poses significant environmental challenges, whereas industrial symbiosis promotes circular resource exchange by enabling the reuse of by-products and waste materials among industries, reducing landfill dependence and raw material consumption. This circular resource flow enhances resource efficiency, lowers costs, and minimizes environmental impact by transforming waste streams into valuable inputs within interconnected industrial networks.

Co-processing Residues

Co-processing residues involves using industrial waste as alternative raw materials or fuels in cement kilns, reducing landfill disposal and conserving natural resources. Industrial symbiosis enhances this practice by facilitating resource exchange between industries, optimizing the recovery and reutilization of co-processing residues to achieve sustainable waste management and lower environmental impact.

Secondary Feedstock Sourcing

Industrial waste typically involves byproducts discarded after manufacturing processes, whereas industrial symbiosis emphasizes secondary feedstock sourcing by repurposing these wastes as raw materials for other industries, reducing resource extraction and environmental impact. This circular approach in industrial symbiosis enhances material efficiency and fosters sustainable production through collaborative waste exchange networks.

Zero-Waste Manufacturing Hubs

Industrial waste typically consists of byproducts and pollutants generated during manufacturing processes, posing significant environmental challenges. Zero-waste manufacturing hubs leverage industrial symbiosis by transforming waste streams into valuable inputs for other industries, promoting resource efficiency and minimizing landfill use.

Material Flow Coupling

Material flow coupling in industrial waste management involves connecting waste output from one process as input for another, minimizing landfill use and resource extraction. Industrial symbiosis exemplifies this by facilitating coordinated material exchanges among multiple industries, enhancing resource efficiency and reducing environmental impact compared to isolated industrial waste disposal.

Symbiotic Waste Scavenging

Symbiotic waste scavenging in industrial symbiosis transforms industrial waste streams into valuable raw materials by facilitating resource exchange among industries, significantly reducing landfill disposal and environmental pollution. This practice enhances circular economy models by promoting collaborative waste reuse, lowering production costs, and fostering sustainable industrial ecosystems.

Industrial Waste vs Industrial Symbiosis Infographic

industrydif.com

industrydif.com